Products

Ebil Tech

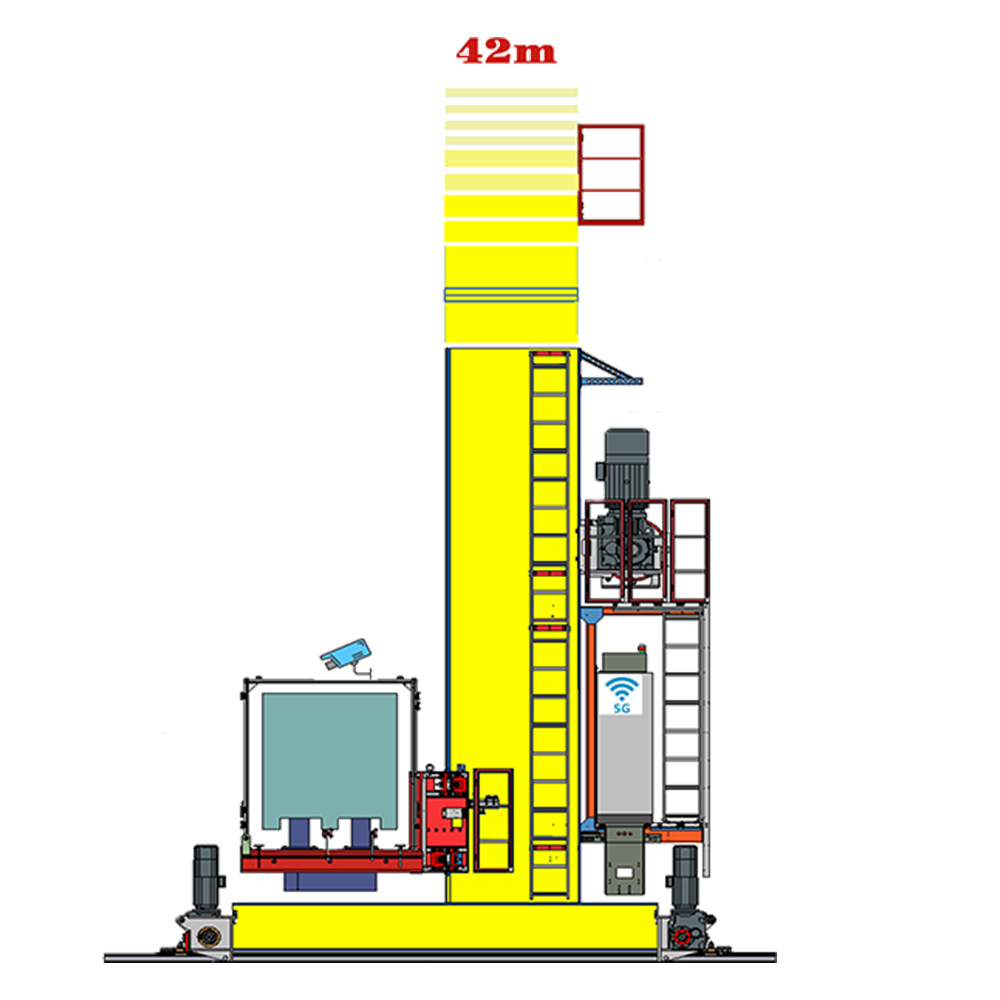

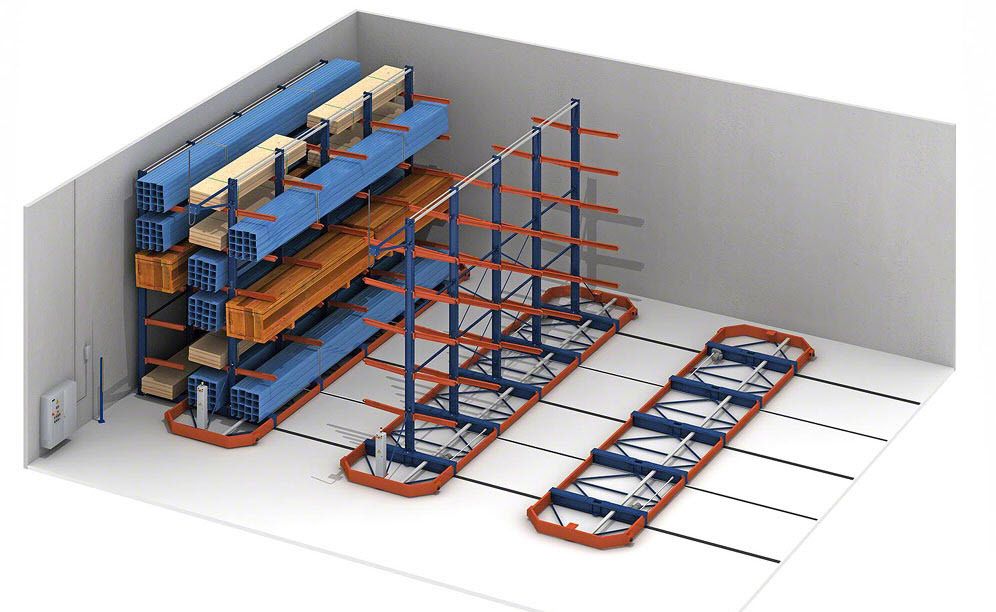

Material Handling Robot

Material Handling Robot is one of our products, we can provide one-stop storage system solutions and products, our products also include Garment Storage Shelving, Multi-Lever Mezzanine Racking, Telescoping beam rack, Automatic Pallet Runner, Drawer Rack for sheets, Medium Duty Rack, Roll-Out Rack, Industrial Steel Platform, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Recife (Brazil), Solomon Islands, Kalachei - Circassian, Socotra, Spain, Kiev (Ukraine), and so on. We are looking forward to cooperate with you. If you are interested in Material Handling Robot.

A Material Handling Robot, also known as an Industrial Robot or Robotic Manipulator, refers to a type of robot specifically designed for handling, moving, and manipulating various types of objects within industrial settings. These robots are widely used in manufacturing, warehouses, and distribution centers to automate material handling tasks and improve operational efficiency.

Material Handling Robots offer several advantages, including increased productivity, improved accuracy, reduced labor costs, and enhanced workplace safety. By automating material handling tasks, these robots contribute to efficient and streamlined operations within industrial environments.

The key characteristics and functionalities of Material Handling Robots:

1. Versatile Manipulation: Material Handling Robots are equipped with mechanical arms and grippers that can handle a wide range of objects, such as boxes, pallets, components, and more. The robot's end effector or gripper can be customized to suit the specific requirements of the task, enabling precise and secure handling of diverse objects.

2. Automated Material Transport: These robots have the capability to autonomously transport objects from one location to another within a workspace. They can navigate through the facility using various guidance systems, such as sensors, cameras, or predefined paths, to efficiently move materials between workstations, conveyor belts, or storage areas.

3. Pick and Place Operations: Material Handling Robots excel in pick and place operations, where they can accurately pick up objects from one location and place them in another, following specific instructions or patterns. This is particularly useful in assembly lines, packaging operations, or order fulfillment processes.

4. Payload Capacity: Material Handling Robots are designed to handle different payload capacities, ranging from a few kilograms to several tons, depending on the specific application. This allows them to lift and move objects of varying sizes and weights.

5. Collaborative Capabilities: Some Material Handling Robots are designed to work collaboratively with human operators. These collaborative robots, also known as cobots, can operate in close proximity to humans, ensuring safe and efficient collaboration. They often include safety features like force sensing or power limitations to prevent injury or accidents.

6. Integration with Automation Systems: Material Handling Robots can be integrated with other automation systems, such as conveyor belts, sensors, or vision systems, to streamline material flow and enhance overall system efficiency. This integration allows for seamless communication and coordination between the robot and the surrounding equipment or control systems.

7. Programming and Control: Material Handling Robots can be programmed to perform specific tasks using various programming methods, including teach pendant programming, offline programming, or programming through graphical interfaces. They can be controlled and monitored through dedicated control systems, enabling operators to manage and optimize the robot's operations.