Automation storage equipment series

- Category : Automation storage equipment series

- Custom service : Yes

- Payment : L/C, T/T, Western Union, D/P, MoneyGram

- Place of delivery : NanJing, China

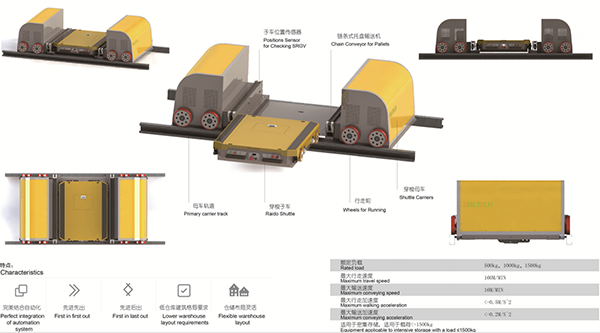

Mother-Child Shuttle

Ebil Tech

provide professional automated warehouse solutions

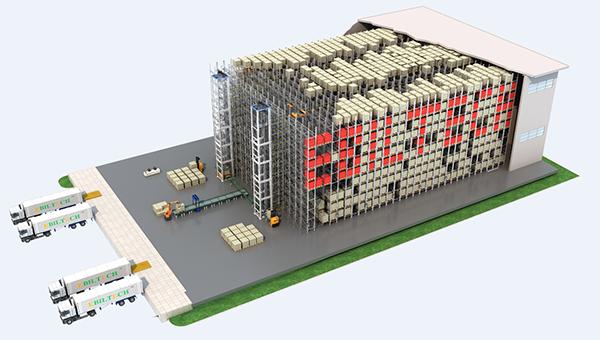

Primary-secondary Mother-Child Shuttle solution

The Mother-Child Shuttle solution is a full automatic and high density storage system which takes the shuttle as a core, it is consist of radio shuttle racks, longitudinal movement shuttle, lateral movement mother shuttle, vertical direction movement elevator, conveyor lines and so on. According to practical application requirements, in-out stock can choose the way of FIFO or FILO, shuttle and mother shuttle can one-to-one match or several-for-one match. With the adjustment of WMS, WCS, equipment scheduling soft management and the whole system to suitable for the single variety and large scale situation, such as food, drink, paper, etc.

Mother-Child Shuttle Advantages and Characteristics

1. Modular design of equipment to achieve system automation;

2. Additional equipment in later stage, and expandable warehouse-in/out efficiency;

3. Out-of-stock mode: first in first out/first in last out;

Ebil Tech Products

Get a quote

The professional supplier that provide intelligent intensive storage equipment and system solutions.