Automation storage equipment series

- Category : Automation storage equipment series

- Custom service : Yes

- Payment : L/C, T/T, Western Union, D/P, MoneyGram

- Place of delivery : NanJing, China

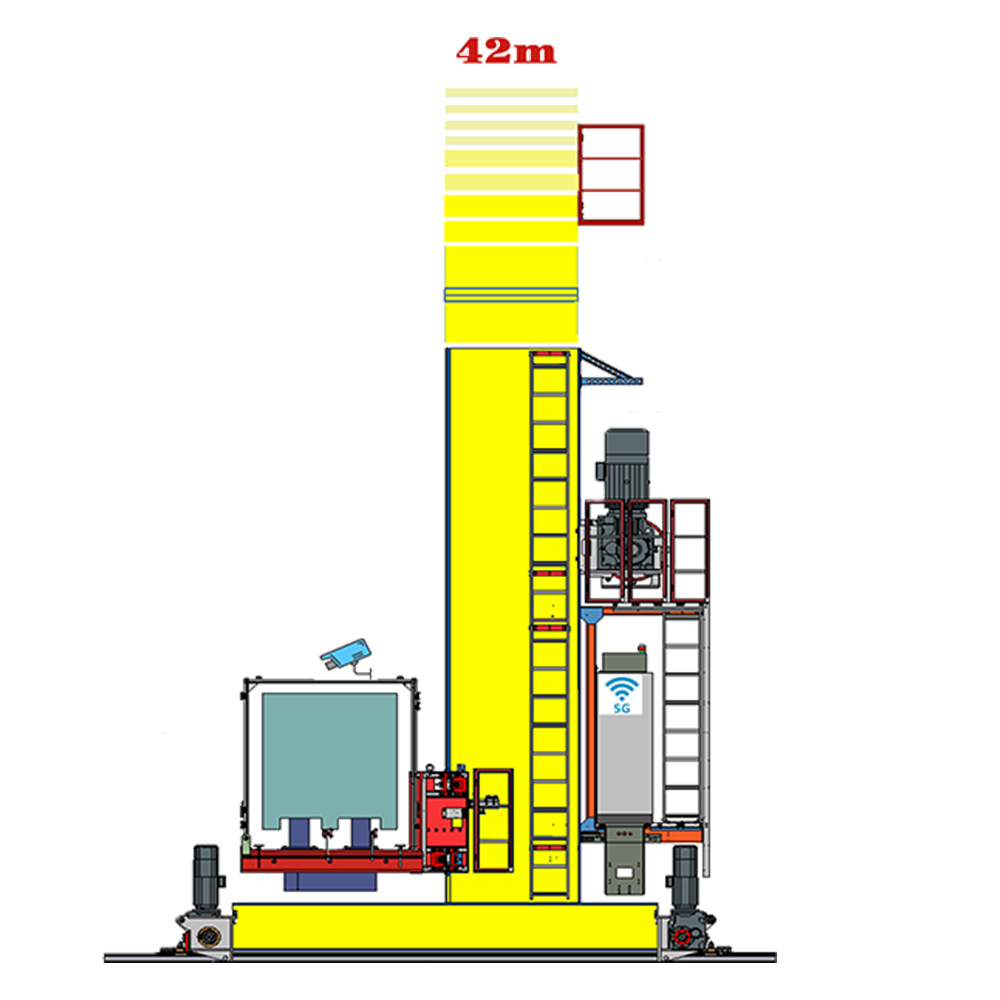

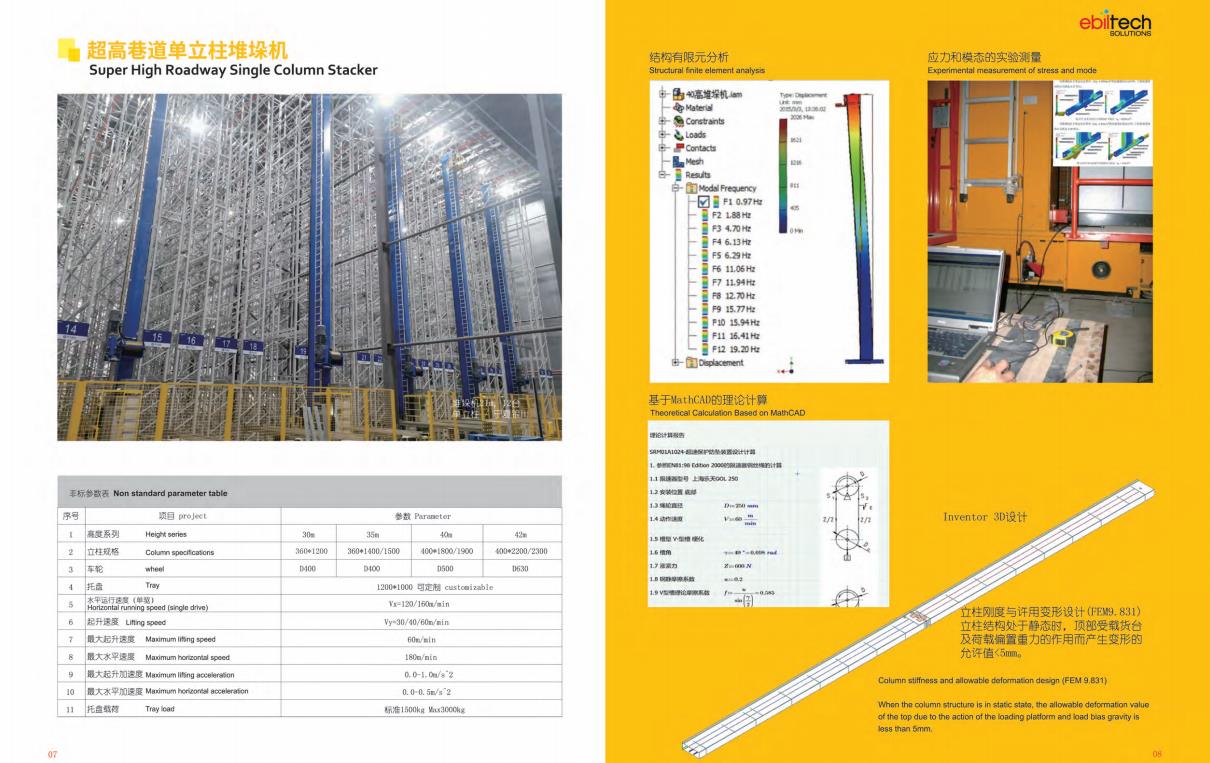

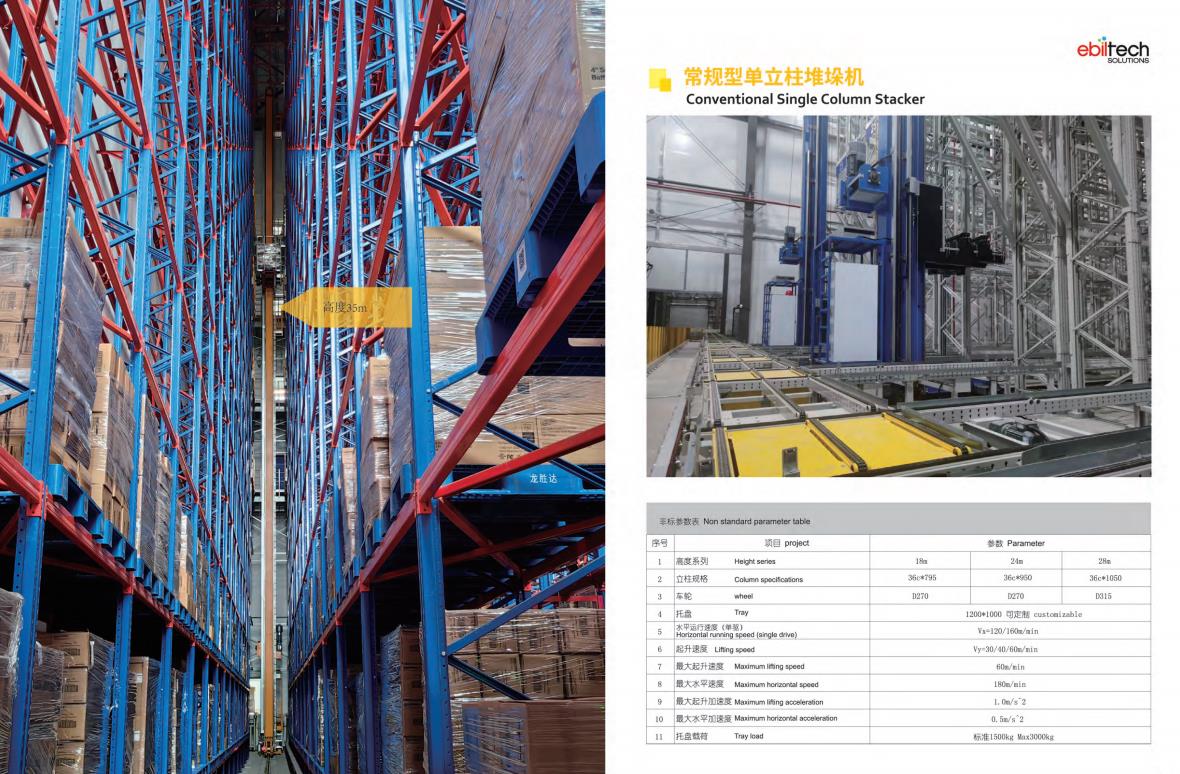

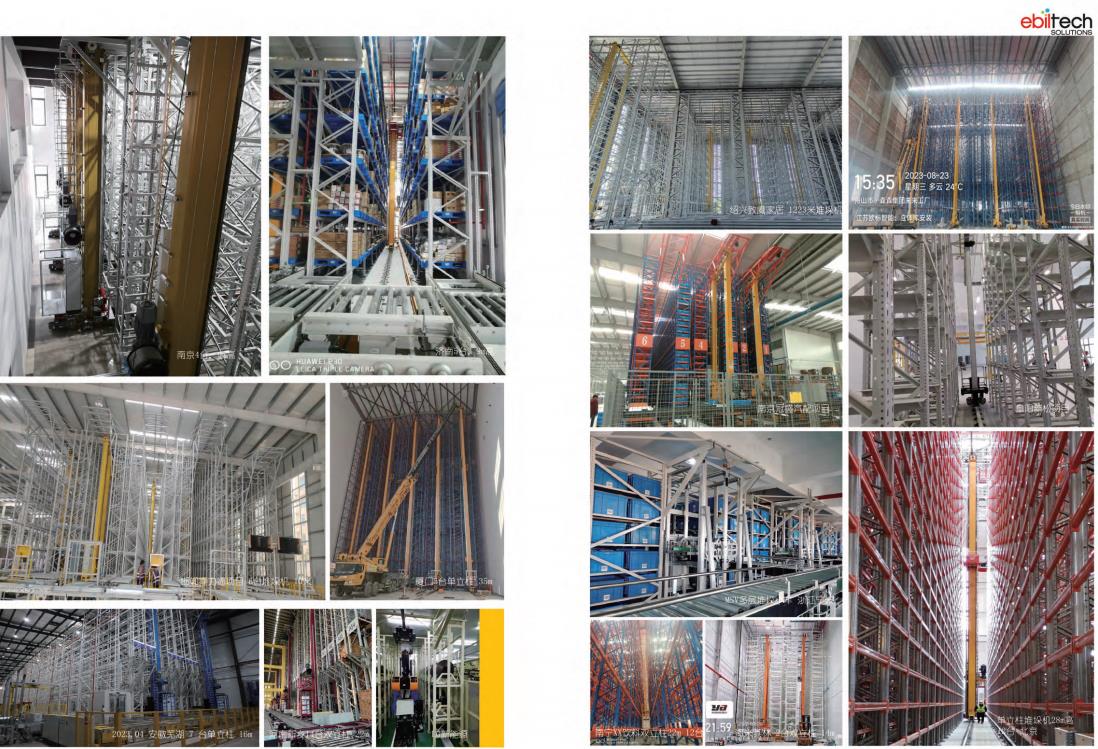

Stacker Crane

Ebil Tech

provide professional automated warehouse solutions

The EBILTECH stacker cranes automate product input and output operations, ensuring fast and precise control of warehouse stock and eliminating manual operating errors.

The key benefits of using stacker cranes within a storage system are:

1. Automation of the product input and output operations

2 .Fast and accurate warehouse controls and updates, facilitating the inventory system

3. Elimination of manual errors

4. he possibility of adjusting to special working conditions (temperature -30°, high humidity)

Stacker Cranes For Warehouse

type:Single Column Stacker,Double Column Stacker,Heavy Stacker,Miniload Stacker Crane

Loading: 500-1000kg,500-1500kg,Loading: 2000-3500kgLoading: 20-50kg

Height: <=12mHeight: <=24mHeight:<=16 mmHeight: <=18 m

Speed: 180m/min,Speed: 180m/min,Speed: 80m/min,Speed: 240m/min

Get a quote

The professional supplier that provide intelligent intensive storage equipment and system solutions.