Automation storage equipment series

- Category : Automation storage equipment series

- Custom service : Yes

- Payment : L/C, T/T, Western Union, D/P, MoneyGram

- Place of delivery : NanJing, China

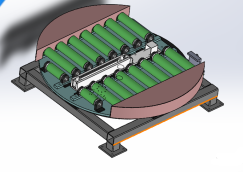

Multi-deck Shuttle carrier

Ebil Tech

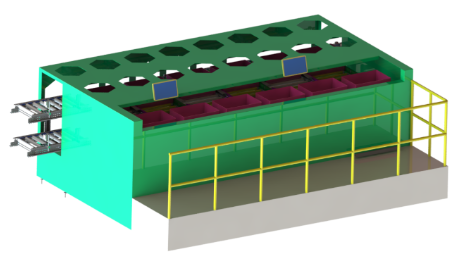

provide professional automated warehouse solutions

Core Functions

Inshuttle car is drove by both AC/DC, running on the guide rail to pick the feedboxes by the clamp to the specified location,

and put the feedboxes from racking entrance to inside.. ,

Advantages

High speed, precise positioning

Both single depth and double depth are available

High picking speed

Specifications

4m/s Max speed

2m/s Max acceleration speed

50KG Max load

PLC Control Unit

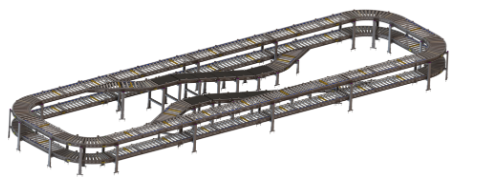

Roller Conveyors for Boxes, Totes and Bins

Increasing manipulation speed between areas. Low maintenance.

The distances within an installation can be covered by different transport devices, which are commonly combined with demanding

requirements in terms of functionality and frequency of each and every component of the system.

The use of driving mechanism and presence-detection systems enabled by mechanical or optical detection devices allows the boxes to be moved under controlled conditions to the desired positions.

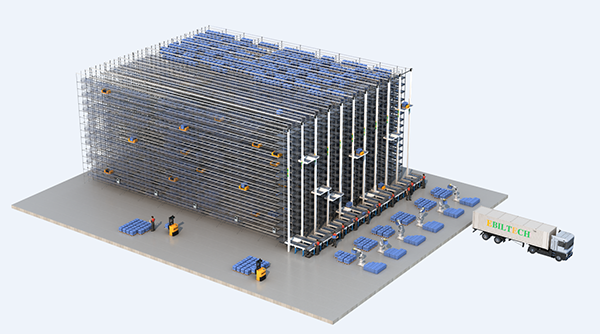

Goods to person

1. Inventory is received at decanting workstations where operators scan bar codes and transfer items into inventory totes.

2. Inventory totes are conveyed and automatically stored in the high-density storage buffer.

3. When needed, inventory totes are retrieved and directed to picking stations.

4. Lights and graphical instructions direct operators to pick the required items from the inventory totes and place them into

order containers.

5. When an order container is complete, it is automatically routed to the packing area.

6. Inventory totes return to the high-density storage buffer.

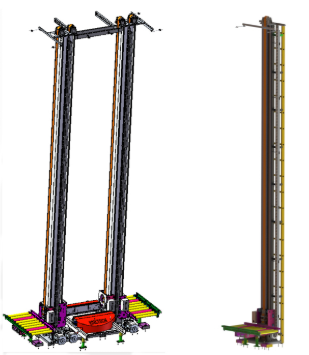

Consists of a racking structure with an integrated shuttle track system, with multidirectional microshuttles transport product bins between storage locations in the rack and stations that can be used for picking and replenishment. A built in lift allows

shuttles to move up and down between rack levels and to the available stations.

Software controls shuttle traffic, maximizing throughput and minimizing order lead times. The user-friendly interface shows

real-time data of the entire system, providing an overview of all every component.

Ebil Tech Products

Get a quote

The professional supplier that provide intelligent intensive storage equipment and system solutions.