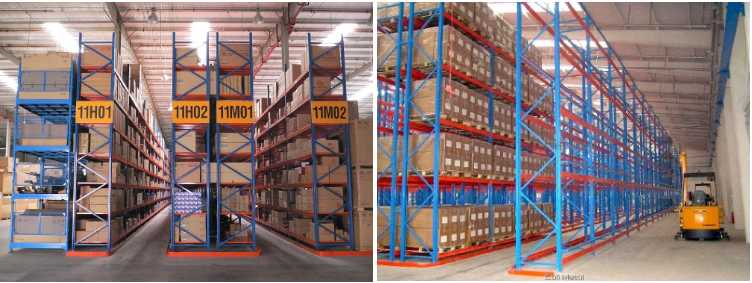

Standard Rack Series

- Category : Standard Rack Series

- Custom service : Yes

- Payment : L/C, T/T, Western Union, D/P, MoneyGram

- Place of delivery : NanJing, China

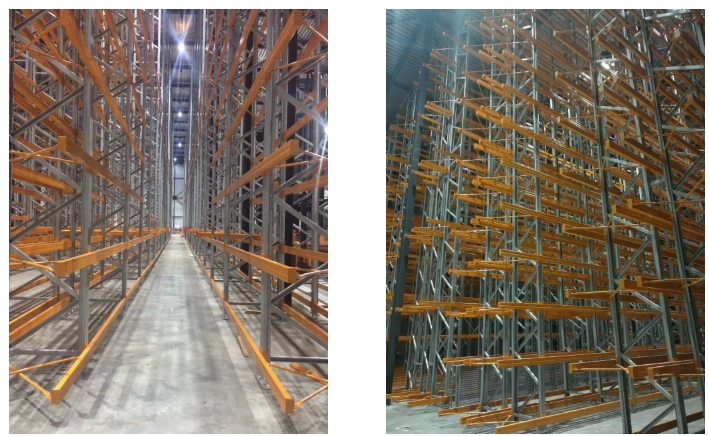

Very Narrow Aisle Rack

Ebil Tech

provide professional automated warehouse solutions

Very Narrow Aisle Rack

Very narrow aisle pallet rack on sale mainly used with the most advantage three ways forklift, occupying small aisle, saving the

space of the warehouse, and can store and pick up products quickly, and cutting down the operating cost. which particularly

suitable for logistic center less than 15 m high.Comparing with the conventional pallet rack,its aisle is much narrower, ordinarily

1600-2000 mm, the space utilization rate will increase about 20%. Guide rails should be installed on the both sides of aisle for the

three-way forklift running.

Advantages

1) This storage racking makes optimum use of floor area and roof height by providing high density storage

2) Pallets can be located, accessed and moved individually;

3) The height between levels can be easily adjusted by 50 mm pitch interval.

4) Strength and rigidity prevents compression damage to goods.

5) Bottom level of pallets can be stored on the floor, lowering structure costs.

6) Rich accessories: upright protector, guide rail, frame barrier, row spacer, wire deckings, steel shelf, etc.

Ebil Tech Products

Get a quote

The professional supplier that provide intelligent intensive storage equipment and system solutions.