High Intensive Racking

- Category : High Intensive Racking

- Custom service : Yes

- Payment : L/C, T/T, Western Union, D/P, MoneyGram

- Place of delivery : NanJing, China

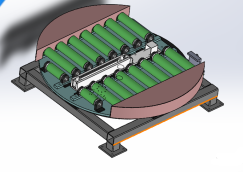

Drive In Pallet Rack

Ebil Tech

provide professional automated warehouse solutions

Drive in rack are exceptionally suited to large stocks of relatively few product types. Use this high density system to reduce

overall square footage requirements by 35% or more, compared to a standard pallet rack configuration.

Advantages

-- LIFO (last in, first out) or FIFO (first in, first out) load methods;

-- Deep lane storage reduces space usage, cuts costs and holds more loads;

-- High volumes, few SKUs;

-- Multiple access aisles eliminated;

-- Extra control over inputs and outputs;

-- More storage density instead of the direct access of Pallet Racks;

-- Specifically designed for your pallets and forklifts;

Ebil Tech Products

Get a quote

The professional supplier that provide intelligent intensive storage equipment and system solutions.