Products

Ebil Tech

Automatic Pallet Runner

Automatic Pallet Runner is one of our products, we can provide one-stop storage system solutions and products, our products also include Steel Mezzanine Platform, Robotic Shuttle, FIFO Racking, Tear Drop Pallet Rack, Four Way Shuttle, Warehouse Racks For Storage, Warehouse Robot, Automated Storage for Sheet, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Indonesia, Casablanca (Morocco), Cameroon, Ho Chi Minh City (Vietnam), Dusseldorf (Germany), Ottawa (Canada), and so on. We are looking forward to cooperate with you. If you are interested in Automatic Pallet Runner.

An Automatic Pallet Runner, also known as a Pallet Runner System, is an automated material handling solution used in warehouses and distribution centers to optimize the storage and retrieval of palletized goods. It is designed to operate within selective racking systems and offers high-density storage capabilities.

The use of an Automatic Pallet Runner system offers several benefits, including increased storage capacity, improved warehouse efficiency, reduced labor costs, and enhanced inventory control. By optimizing space utilization and automating pallet movements, it provides an efficient and space-saving solution for warehouses with high-density storage requirements.

Here are the key features and functionalities of an Automatic Pallet Runner:

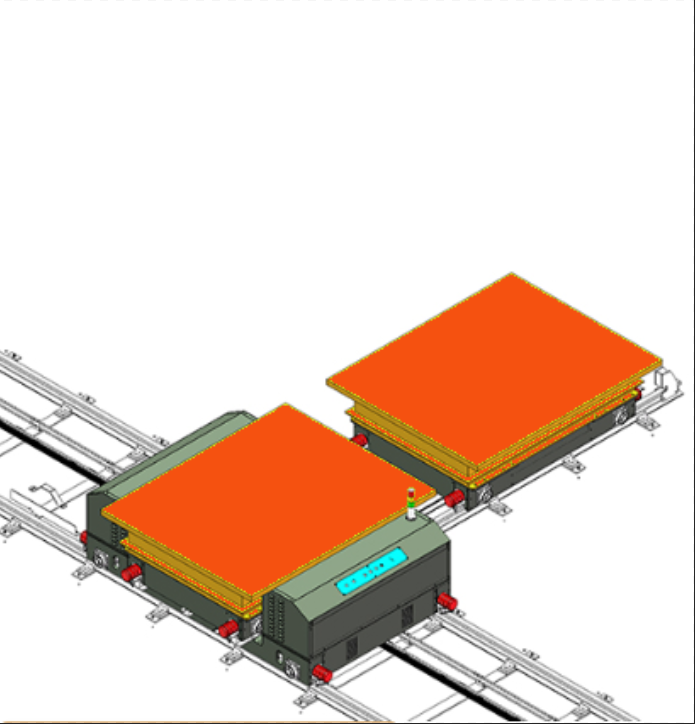

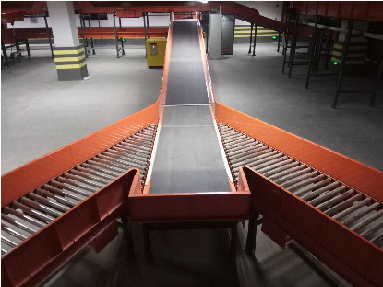

1. Pallet Runner Device: The Automatic Pallet Runner system consists of a motorized shuttle device that runs on rails or tracks within the racking system. The shuttle can move horizontally along the depth of the racking, carrying and transporting pallets.

2. Selective Racking System: The Pallet Runner System is compatible with selective racking systems. These racking systems consist of multiple levels of pallet positions, and the shuttle device can access and move between these levels. It allows for efficient utilization of vertical space and high-density storage.

3. Automated Storage and Retrieval: The Pallet Runner System provides automated storage and retrieval of pallets. The shuttle device is capable of entering the racking system, locating the designated pallet position, and depositing or retrieving pallets as per instructions received from a control system.

4. Remote or Central Control: The Pallet Runner System can be operated using a remote control device held by an operator, or it can be integrated into a central control system. In the latter case, the system can receive commands and manage the movements of multiple shuttle devices simultaneously, optimizing the overall operation.

5. High Throughput and Efficiency: By automating the storage and retrieval processes, the Automatic Pallet Runner system offers high throughput and operational efficiency. It reduces the time required for pallet handling tasks and enables faster storage and retrieval operations compared to manual methods.

6. Compatibility with Various Pallet Sizes and Loads: The Pallet Runner System can accommodate different pallet sizes and load capacities. The design of the shuttle device and the racking system can be adjusted to handle various pallet dimensions, ensuring flexibility in handling different types of products.

7. Integration with Warehouse Management Systems: Automatic Pallet Runner systems integrate with Warehouse Management Systems (WMS) or Warehouse Control Systems (WCS). This integration enables real-time communication, allowing the system to receive instructions, update inventory data, and synchronize its operations with other equipment and processes in the warehouse.

8. Safety Features: Automatic Pallet Runner systems incorporate safety features to ensure safe operation. These may include sensors to detect obstacles or obstructions, emergency stop mechanisms, and safety protocols to prevent accidents or damage to goods.