Products

Ebil Tech

Rail Guided Vehicle

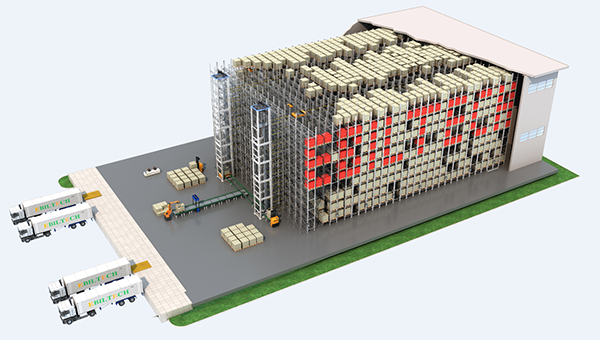

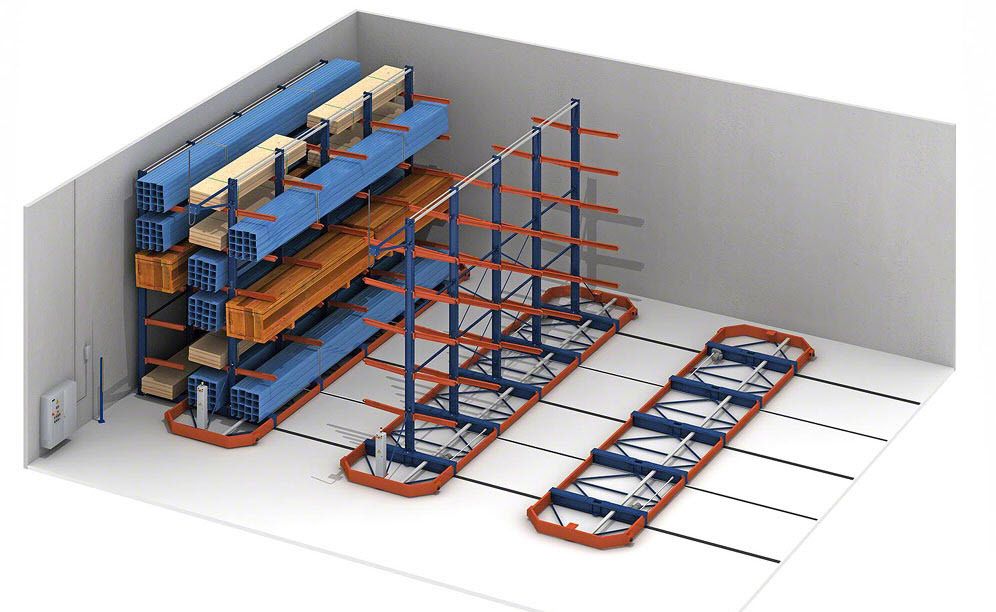

Rail Guided Vehicle is one of our products, we can provide one-stop storage system solutions and products, our products also include VNA Warehouse Rack, ASRS Rack, Rail Guided Vehicle, Electric Mobile Rack, Steel Mezzanine Rack, Four-Way Forklift, American Style Rack, Automated Multi-Level Shuttle Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Glasgow (Scotland, UK), Southampton (UK), Vienna (Austria), Aves Island, Katowice (Poland), Hyderabad (India), and so on. We are looking forward to cooperate with you. If you are interested in Rail Guided Vehicle.

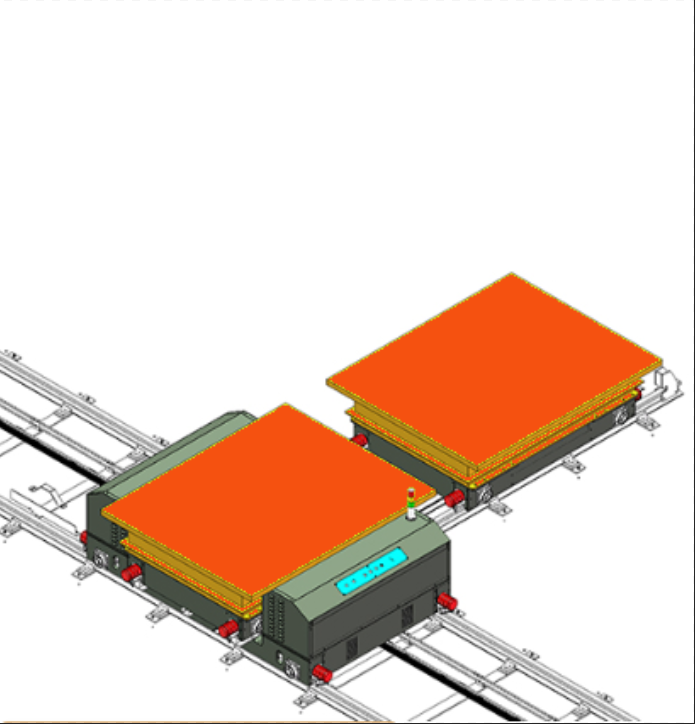

A Rail Guided Vehicle (RGV), also known as an Automated Guided Vehicle (AGV) with rail guidance, is a type of autonomous mobile robot that operates on a fixed rail system. It is designed to transport goods or materials within a facility, such as a warehouse, manufacturing plant, or distribution center.

RGVs typically consist of a vehicle or platform equipped with wheels that run along rails embedded in the floor. The rails provide guidance and control for the RGV's movement within the facility. The rails can be either magnetic or physical, depending on the specific system design.

Here are some key features and characteristics of Rail Guided Vehicles:

1. Rail Guidance: The RGV's movement is strictly controlled along the fixed rail system. The rails act as a track, guiding the RGV to specific locations within the facility. This guidance system ensures precise and repeatable movement, allowing for efficient and accurate material transport.

2. Autonomy: RGVs are autonomous in nature, meaning they operate without the need for human intervention or direct control. They are equipped with sensors, navigation systems, and onboard computers that enable them to navigate along the rail system, avoid obstacles, and make decisions about their path and actions.

3. Load Capacity: RGVs are designed to handle a wide range of loads, from small items to heavy pallets or containers. The load capacity of an RGV depends on its specific design and configuration, with some models capable of transporting several tons of weight.

4. Versatility: RGVs can be customized and adapted to different material handling tasks. They can be equipped with various types of load-handling devices, such as forks, conveyors, or lift platforms, to accommodate different types of goods and handling requirements.

5. Integration with Systems: RGVs can be integrated with other systems within a facility, such as warehouse management systems (WMS) or manufacturing execution systems (MES). This integration allows for seamless coordination and communication between the RGVs and other automated or manual processes in the facility.

RGVs provide benefits such as increased efficiency, reduced labor costs, improved safety, and enhanced accuracy in material handling operations. They are commonly used in industries where repetitive material transport tasks are required, such as logistics, manufacturing, and distribution.

It's important to note that specific RGV designs and capabilities can vary among manufacturers and depend on the requirements of the facility.