Products

Ebil Tech

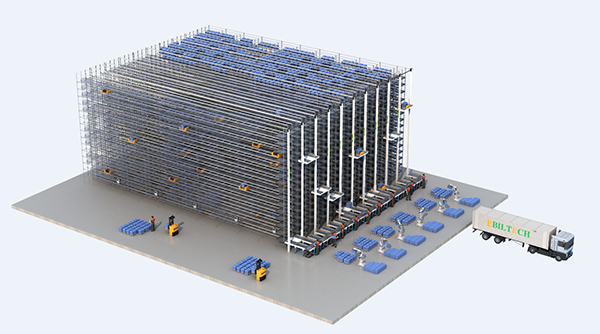

Warehouse Rack System

Warehouse Rack System is one of our products, we can provide one-stop storage system solutions and products, our products also include FIFO Flow Rack, Steel Mezzanine Rack, Smart Rack System, Automatic Radio Shuttle, Drawer Rack for lengthy goods, Radio Shuttle Rack, Storage Radio Shuttle, Autonomous Rail Vehicle, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Christchurch (New Zealand), Pittsburgh (United States), Yerevan (Armenia), Chennai (India), Kazan (Russia), Dublin (Ireland), and so on. We are looking forward to cooperate with you. If you are interested in Warehouse Rack System.

A warehouse rack system, also known as a pallet racking system, is a storage solution designed to efficiently organize and store goods in a warehouse or distribution center. It consists of various components that work together to provide a structured framework for storing palletized or non-palletized items.

1. Components of a Warehouse Rack System:

- Uprights: Vertical frames or columns that provide the structural support for the rack system.

- Beams: Horizontal load-bearing elements that connect to the uprights and hold the pallets or items.

- Wire Decking: Metal mesh panels placed on the beams to provide support for non-palletized items or increased safety.

- Bracing: Diagonal or horizontal bars that reinforce the stability of the rack system.

- Footplates: Metal plates at the base of the uprights to distribute the weight and anchor the rack system to the floor.

2. Types of Warehouse Rack Systems:

- Selective Pallet Rack: The most common type, featuring upright frames and horizontal beams that allow direct access to each pallet.

- Drive-In/Drive-Through Rack: Designed for high-density storage, where forklifts can drive into the rack structure to load and unload pallets.

- Push Back Rack: Utilizes inclined rails and carts that allow pallets to be pushed back and stored in a "last in, first out" (LIFO) configuration.

- Cantilever Rack: Suitable for storing long and bulky items, such as pipes, lumber, or furniture, with horizontal arms extending from uprights.

- Pallet Flow Rack: Uses inclined rollers or wheels to allow pallets to flow from the loading end to the picking end by the force of gravity.

- Mezzanine Rack: Combines rack storage with a raised platform to create additional levels for storage or workspace.

3. Benefits of Warehouse Rack Systems:

- Efficient Space Utilization: Rack systems maximize vertical space, allowing for high-density storage and optimizing the warehouse footprint.

- Improved Accessibility: By organizing goods vertically, rack systems provide easy access to stored items for loading, unloading, and picking.

- Inventory Management: Rack systems enable systematic organization, making it easier to track, manage, and control inventory levels.

- Safety and Protection: Properly designed rack systems incorporate safety features like load beams, wire decking, and column protectors to protect goods and prevent accidents.

- Scalability: Warehouse rack systems are modular and can be expanded or reconfigured as storage needs change, providing flexibility and adaptability.

When implementing a warehouse rack system, factors such as load capacity, aisle width, forklift compatibility, and local regulations should be considered. It is advisable to consult with experts or professionals in warehouse design and storage solutions to ensure the optimal configuration for your specific needs.