Products

Ebil Tech

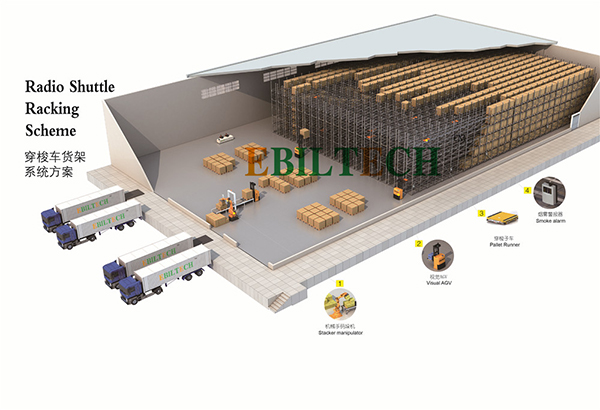

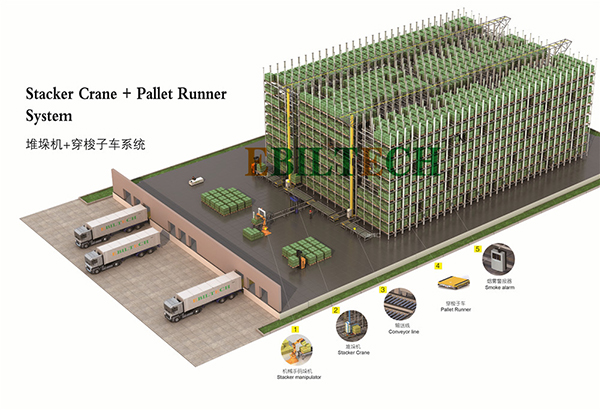

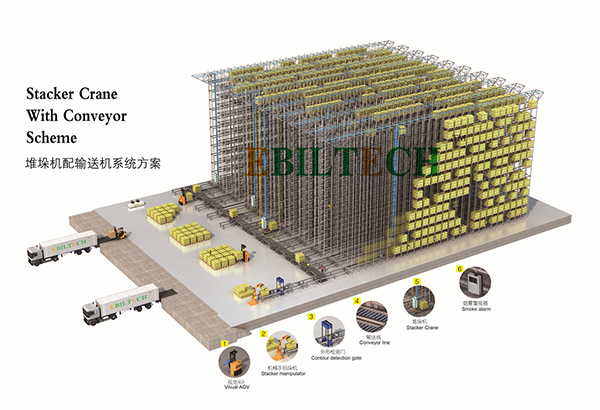

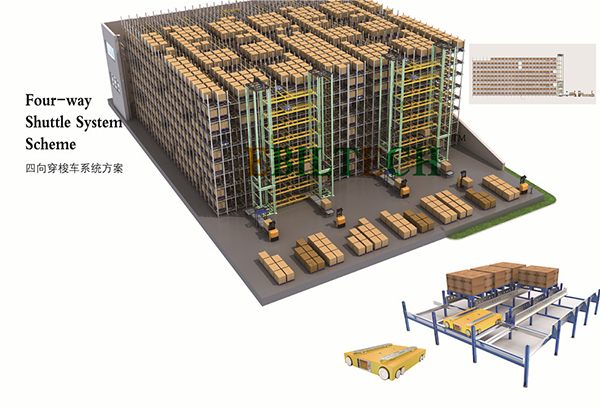

Pallet Shuttle System

Pallet Shuttle System is one of our products, we can provide one-stop storage system solutions and products, our products also include Cargo Elevator, Steel Racking, Mobile Shelving System, Electric Extendable Cantilever Shelving, Pallet Flow Racking, Medium-Duty Racking System, ASRS Rack, Motor-Driven Cantilever Racking System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Grenoble (France), Mexico City (Mexico), Katowice (Poland), New Delhi (India), Rio de Janeiro (Brazil), Niger, and so on. We are looking forward to cooperate with you. If you are interested in Pallet Shuttle System.

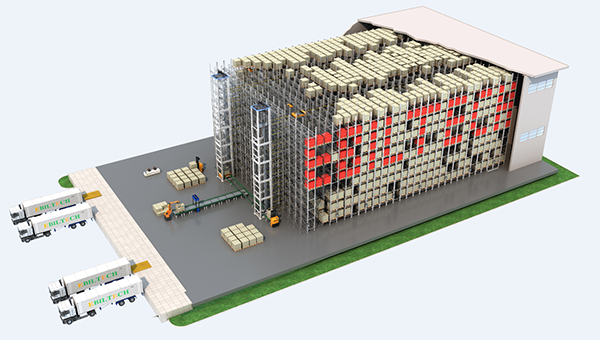

A Pallet Shuttle System, also known as a Pallet Shuttle Racking System or Pallet Shuttle Storage System, is a type of high-density storage solution used in warehouses and distribution centers to maximize storage capacity and facilitate efficient pallet handling.

Pallet Shuttle Systems offer several benefits, including increased storage density, optimized space utilization, efficient pallet handling, and improved inventory management. By using shuttles to move pallets within the deep storage lanes, these systems can significantly increase storage capacity compared to traditional selective racking systems. They also allow for better organization and accessibility of pallets, reducing the time and effort required for storage and retrieval operations.

The specific design and capabilities of Pallet Shuttle Systems may vary among manufacturers and based on the specific requirements and constraints of the warehouse or distribution center.

Here are the key features and components of a Pallet Shuttle System:

1. Pallet Shuttles: The Pallet Shuttle System involves the use of specialized pallet shuttles or carriers. These shuttles are battery-powered devices that can autonomously move within the racking system to transport and position pallets. They are designed to fit within the depth of the storage lanes and can carry one or more pallets at a time.

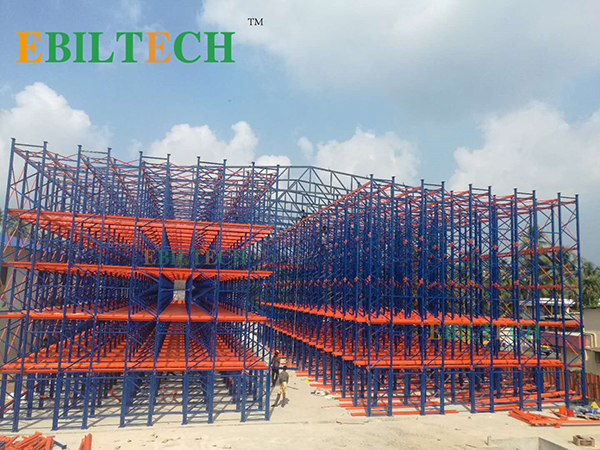

2. Racking Structure: The Pallet Shuttle System incorporates a racking structure consisting of multiple levels of racks with deep storage lanes. The shuttles operate within these lanes, allowing for the dense storage of pallets. The racking structure is designed to support the weight of the pallets and provide stability.

3. Guide Rails: The storage lanes within the Pallet Shuttle System are equipped with guide rails or tracks. These rails help guide the movement of the shuttles along the lanes, ensuring accurate positioning and preventing collisions.

4. Control System: The Pallet Shuttle System is controlled by a central control system that manages the operation of the shuttles. The control system can be integrated with warehouse management systems (WMS) or other software to coordinate the movement of the shuttles, monitor inventory, and optimize storage and retrieval operations.

5. Loading and Unloading: Pallets are loaded and unloaded from the Pallet Shuttle System using forklifts or stacker cranes at the entry and exit points of the storage lanes. The shuttles move within the lanes to position the pallets for storage or retrieval, eliminating the need for forklifts to enter the storage lanes.

6. Safety Features: Pallet Shuttle Systems incorporate safety features to ensure the safety of personnel and equipment. These features may include sensors to detect obstacles or obstructions, emergency stop buttons, and safety interlocks.