Products

Ebil Tech

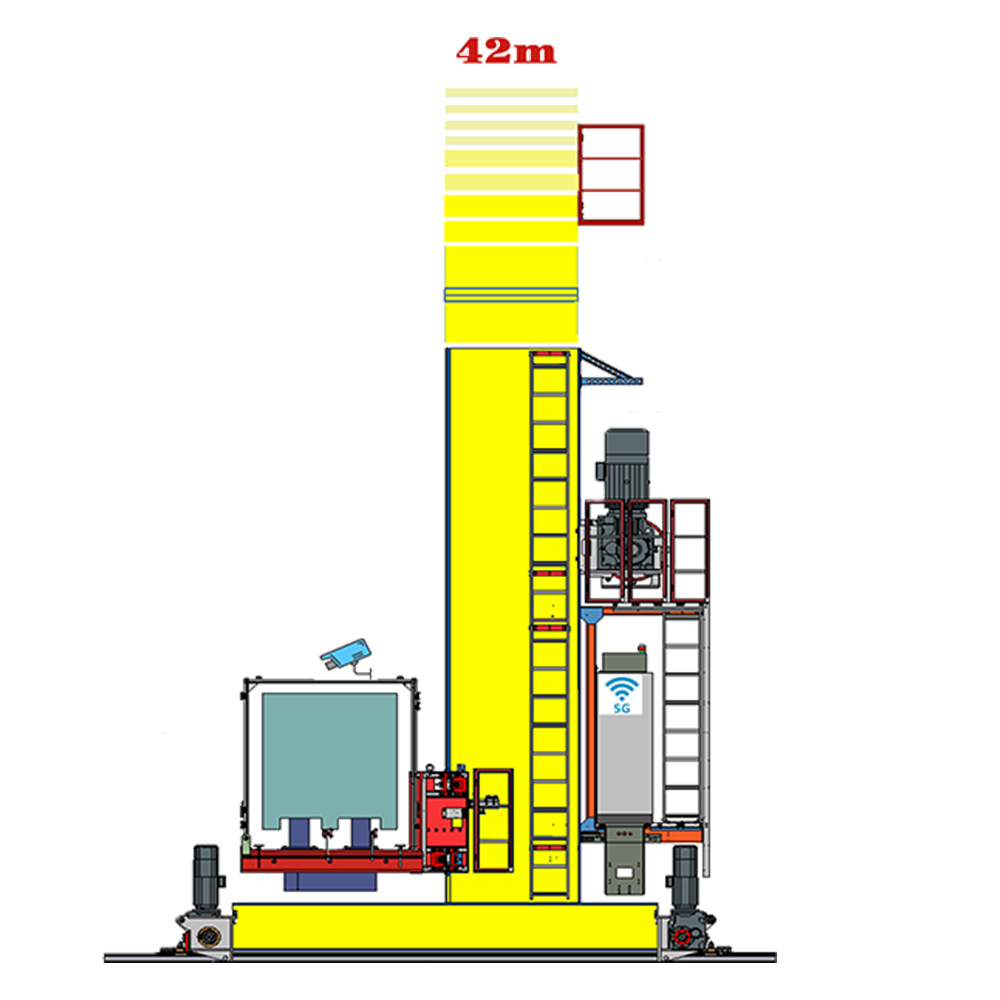

Stacker Crane

Stacker Crane is one of our products, we can provide one-stop storage system solutions and products, our products also include Low-Temperature Storage Rack, Cold Storage Rack, High Density Mobile Shelving System, ASRS, Drawer Rack for Sheets, Mother Child Shuttle, Medium-Duty Shelving Unit, Storage Stacker, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as San Francisco (California, USA), Aguascalientes (Mexico), Mauritania, Udmurt, Dusseldorf (Germany), Liege (Belgium), and so on. We are looking forward to cooperate with you. If you are interested in Stacker Crane.

A Stacker Crane, also known as a Stacking Crane or automated storage and retrieval system (AS/RS) Crane, is a type of automated lifting equipment used in warehouses and distribution centers for vertical storage and retrieval of goods. It is designed to maximize storage density, improve efficiency, and streamline material handling operations.

Stacker Cranes offer several benefits, including increased storage capacity, improved throughput, reduced labor requirements, and enhanced inventory control. They optimize vertical space utilization, enable efficient storage and retrieval of goods, and contribute to smoother and more efficient warehouse operations.

The specific design and capabilities of Stacker Cranes may vary among manufacturers and based on the intended application and requirements of the facility.

Here are the key features and components of a Stacker Crane:

1. Vertical Movement: The primary function of a Stacker Crane is to move vertically within the facility to access different levels of storage. It typically operates on a track or guideway system that allows it to move along the aisles between storage racks or shelves. The crane is equipped with a lifting mechanism that raises and lowers the goods or pallets.

2. Lifting Mechanism: The lifting mechanism of a Stacker Crane consists of forks or platforms that are used to lift and transport goods or pallets. The forks can be adjusted to accommodate different load sizes and shapes. The lifting mechanism is controlled electronically to ensure precise positioning and smooth operation.

3. Horizontal Movement: In addition to vertical movement, Stacker Cranes can also move horizontally within the aisles to access specific storage locations. They can travel along the length of the aisle to reach the desired rack or shelf. The horizontal movement is typically guided by rails or tracks.

4. Control System: Stacker Cranes are controlled by a software-based control system that manages their operations. The control system coordinates the movement of the crane, receives commands for storage or retrieval tasks, and communicates with other warehouse management systems (WMS) or automation software. It allows for efficient task assignment, monitoring, and optimization of material handling operations.

5. Safety Features: Stacker Cranes incorporate various safety features to ensure the safety of personnel and prevent accidents. These features may include collision avoidance sensors, emergency stop buttons, safety interlocks, and safety zones to prevent unauthorized access to the crane's path.

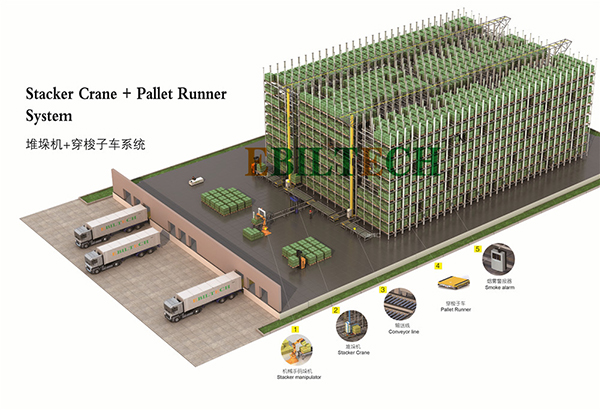

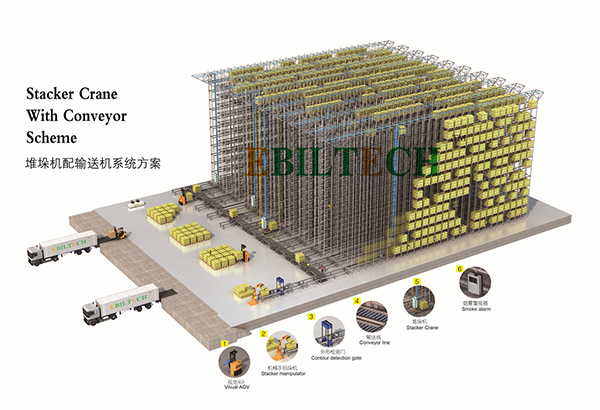

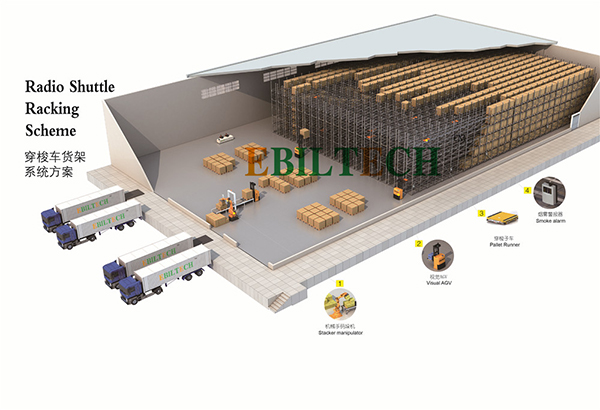

6. Integration with Warehouse Infrastructure: Stacker Cranes can be integrated with the overall infrastructure of a warehouse or distribution center. They can interface with conveyor systems, automated storage racks, or other equipment to facilitate seamless material flow and optimize storage and retrieval operations.

Stacker cranes are commonly used in automated storage and retrieval systems (AS/RS) to handle the vertical movement of goods within a warehouse or distribution center. There are several types of stacker cranes available, each designed for specific applications and storage configurations. Here are some of the main types:

1. Single-Mast Stacker Crane: This type of stacker crane consists of a single vertical mast that carries the horizontal load-handling device, such as a fork or a gripper. The mast moves up and down along a track or rail system, allowing the stacker crane to access different storage levels.

2. Double-Mast Stacker Crane: Double-mast stacker cranes have two vertically arranged masts connected by a bridge or horizontal beam. This design provides enhanced stability and load capacity compared to single-mast cranes. The load-handling device is typically mounted on the lower mast, while the upper mast provides additional support and stability during lifting operations.

3. Bridge-Mast Stacker Crane: Bridge-mast stacker cranes feature a horizontal bridge or beam that spans the width of the storage aisle. The load-handling device is mounted on the bridge, which can move horizontally along the aisle to access different storage positions. The vertical movement is achieved by a mast attached to the bridge.

4. Satellite Stacker Crane: A satellite stacker crane, or satellite vehicle, is a type of stacker crane that performs both horizontal and vertical movements. It consists of a mast-mounted vehicle that can move along a rail system and rotate within the aisle to access storage positions from multiple sides. Satellite stacker cranes are often used in high-density storage systems, such as dense pallet racking or deep-lane storage.

5. Mini-Load Stacker Crane: Mini-load stacker cranes are designed for handling smaller loads, such as totes or cartons, in high-speed order fulfillment operations. They are typically compact in size and can operate in narrow aisles. Mini-load stacker cranes often feature telescopic forks or grippers to handle multiple items simultaneously.

These are some of the common types of stacker cranes used in automated storage and retrieval systems. The choice of stacker crane depends on factors such as the type and size of the stored items, the required load capacity, the available space, and the desired level of automation and throughput. Each type has its own advantages and considerations, so it's important to select the appropriate stacker crane based on the specific requirements of the warehouse or distribution center.