Products

Ebil Tech

Heavy Duty Rack

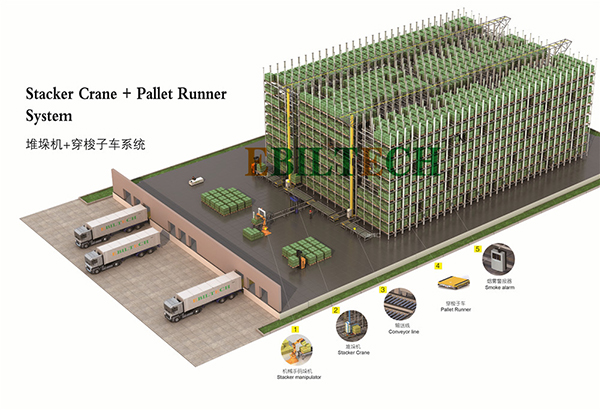

Heavy Duty Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Eletric Double Column Stacker Crane, Teardrop Storage Rack, Warehouse Pallet Racking, Honeycomb Rack, Roadway Stacker Crane, Pallet Flow Rack System, ASRS Rack, Automated Mobile Storage System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Fiji, Kyrgyzstan, Djibouti, Munich (Bavaria, Germany), Leon (Spain), Caracas (Venezuela), and so on. We are looking forward to cooperate with you. If you are interested in Heavy Duty Rack.

Heavy-duty racks, also known as industrial racks or heavy-duty shelving systems, are designed to store and organize large, bulky, and heavy items in warehouses, manufacturing facilities, and other industrial settings. These racks are built to withstand high weight capacities and provide robust support for the stored materials. Here's some information about heavy-duty racks:

1. Construction and Load Capacity:

- Frame Structure: Heavy-duty racks typically consist of upright frames made of durable materials such as steel or aluminum. The frames provide vertical support and stability for the entire rack system.

- Load Beams and Decking: Load beams, also known as cross beams or horizontal beams, connect the upright frames and provide the primary support for the stored items. The beams are adjustable and can accommodate various load sizes.

- Decking Options: Heavy-duty racks may have different decking options, such as wire mesh decking, particle board, or steel panels. The choice of decking depends on the specific requirements of the stored items, including load capacity, ventilation needs, and fire safety regulations.

- Load Capacity: Heavy-duty racks are designed to handle substantial weight capacities, often ranging from a few thousand pounds to several tons per shelf level. The load capacity depends on factors such as the dimensions and thickness of the beams, the quality of materials used, and the rack's overall design.

2. Types of Heavy-Duty Racks:

- Bolted Shelving: Bolted shelving systems consist of individual shelves that are bolted onto the upright frames. This type of heavy-duty rack allows for easy assembly and disassembly and can be adjusted to accommodate changing storage needs.

- Pallet Racking Systems: Pallet racking systems, such as selective pallet racking or double deep racking, can also be considered heavy-duty racks. These systems are designed to store palletized goods and offer high load capacities and versatility.

- Cantilever Racks: Cantilever racks are specifically designed to store long, bulky items such as lumber, pipes, or steel bars. These racks feature arms that extend outward from upright columns, providing easy access to stored items.

3. Advantages:

- High Load Capacity: Heavy-duty racks are engineered to withstand heavy loads, making them suitable for storing and organizing large, heavy items.

- Durability and Sturdiness: These racks are constructed using strong materials and robust structures, ensuring long-lasting performance even in demanding industrial environments.

- Versatility: Heavy-duty racks can be customized and configured to accommodate a wide range of item sizes and weights. They can be adjusted, expanded, or reconfigured to adapt to changing storage needs.

- Efficient Space Utilization: Heavy-duty racks maximize vertical storage space, allowing for efficient utilization of available warehouse or industrial floor space.

- Easy Access and Retrieval: The design of heavy-duty racks enables easy access and retrieval of stored items, facilitating efficient inventory management and order picking processes.

4. Safety Considerations:

- Proper Installation: It is crucial to follow manufacturer guidelines and ensure that heavy-duty racks are installed correctly, including proper anchoring to the floor or wall for stability and load-bearing capacity.

- Load Distribution: Load weight should be distributed evenly across the rack system to maintain stability and prevent overloading of individual shelves or beams.

- Regular Inspections: Regular inspections of heavy-duty racks are essential to identify any signs of damage or wear and tear. Damaged components should be repaired or replaced promptly to maintain the integrity and safety of the rack system.

- Load Securement: Proper load securement techniques, such as using strapping or pallet wraps, should be employed to prevent items from shifting or falling off the racks.

When considering heavy-duty racks, it is important to assess your specific storage requirements, including the type of items to be stored, their dimensions, and weight. Consulting with rack system suppliers or material handling experts can help determine the most suitable heavy-duty rack system for your needs, considering factors such as load capacity, space utilization, and safety considerations.