Products

Ebil Tech

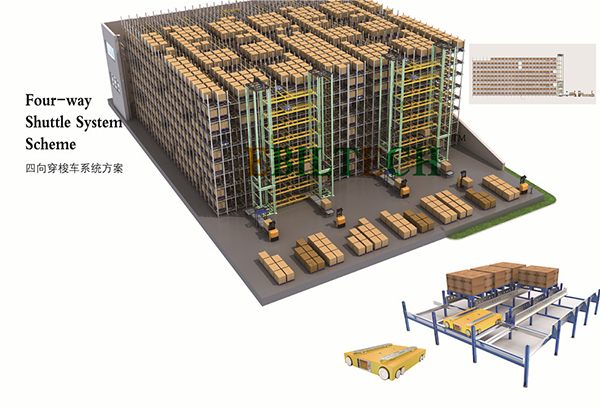

Four Way Shuttle

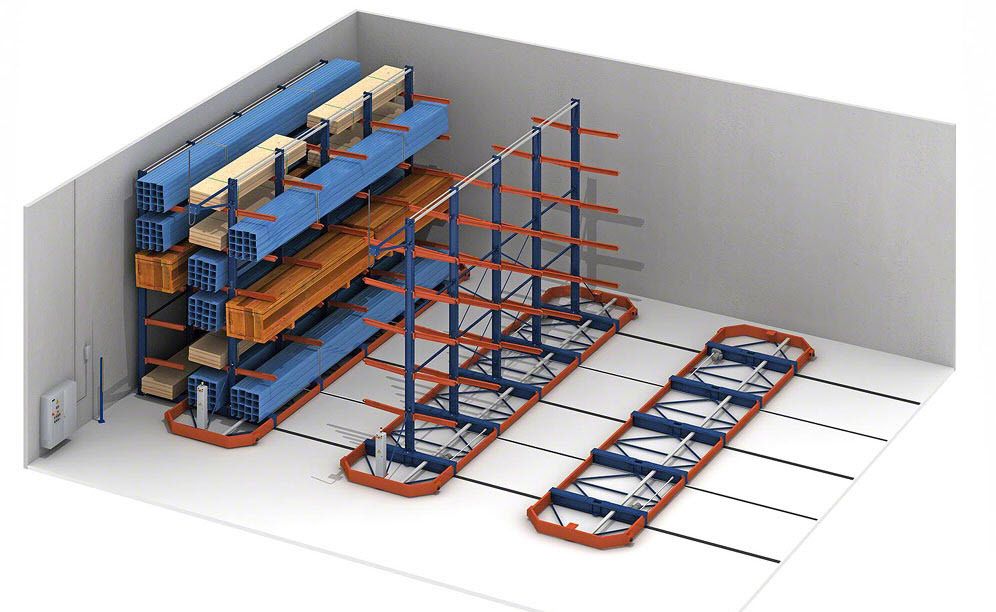

Four Way Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Steel Mezzanine Platform, Storage Racks For Warehouse, Telescoping beam rack, Radio Shuttle, Retractable cantilever rack, Extendable cantilever rack, Electric Mobile Racking, ASRS Shuttle Racking, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Windhoek (Namibia), Almaty (Kazakhstan), San Antonio (United States), Doha (Qatar), Laos, Iceland, and so on. We are looking forward to cooperate with you. If you are interested in Four Way Shuttle.

A Four-Way Shuttle, also known as a four-directional shuttle, is a specialized type of shuttle system used in automated storage and retrieval systems (AS/RS) or warehouse automation. It is designed to move goods or loads horizontally in four different directions within a racking structure, allowing for efficient storage and retrieval operations.

The use of four-way shuttles in warehouse automation can bring several benefits, including increased storage capacity, improved picking efficiency, reduced labor requirements, and enhanced inventory control. They are often employed in high-density storage environments, such as cold storage facilities, automotive parts distribution centers, or retail warehouses, where space optimization and efficient load handling are crucial.

Here are the key features and functions of a four-way shuttle:

1. Horizontal Movement: A four-way shuttle can move in four directions: forward, backward, left, and right. This multi-directional capability enables it to access storage locations in different aisles and move between multiple storage lanes within the racking structure.

2. Autonomous Operation: The four-way shuttle is typically equipped with autonomous or semi-autonomous capabilities, allowing it to operate independently or under minimal human intervention. It can follow predetermined routes or instructions to navigate within the warehouse or distribution center.

3. High Storage Density: By moving in four directions, the four-way shuttle maximizes the storage density within the racking structure. It can access storage locations in multiple aisles and reach deep into the lanes, optimizing the utilization of available space.

4. Flexibility and Adaptability: The Four-Way Shuttle System offers flexibility and adaptability in handling various load sizes and configurations. It can accommodate different types of storage units, such as pallets, bins, or totes, and adjust its movements and operations accordingly.

5. Integration and Control: The four-way shuttle system is typically integrated with a central control system or warehouse management system (WMS). This integration allows for seamless coordination, task assignment, and real-time monitoring of the shuttle's operations within the overall warehouse automation system.