Products

Ebil Tech

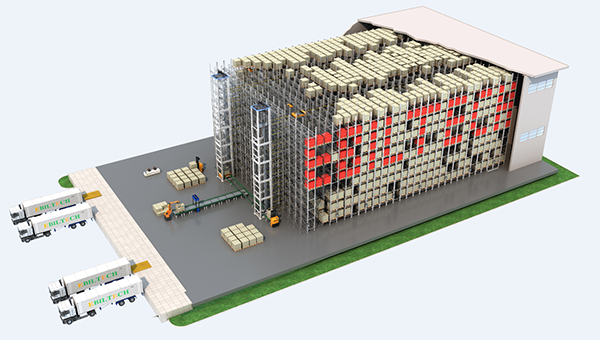

Shuttle Transporter

Shuttle Transporter is one of our products, we can provide one-stop storage system solutions and products, our products also include Bars and Tubes Storage Systems, Automated Mobile Storage System, Storage Rack, 4-Way Shuttle Rack, Multi-Lever Mezzanine Racking, Teardrop Storage Rack, Pallet Racking, Robotic Shuttle, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Cuba, San Juan (Puerto Rico, USA), Kansas City (United States), San Diego (California, USA), United Arab Emirates, Bursa (Turkey), and so on. We are looking forward to cooperate with you. If you are interested in Shuttle Transporter.

In the context of warehousing and material handling, a warehouse shuttle transporter typically refers to an automated or semi-automated system used to transport goods or inventory within a warehouse or distribution center. It is designed to optimize the movement of goods and improve operational efficiency. The specific design, capabilities, and terminology of a warehouse shuttle transporter system may vary depending on the manufacturer or the specific implementation. Different companies may use different names or variations of the term to describe their particular automated material handling solutions for warehouses.

A warehouse shuttle transporter system typically consists of the following components:

1. Shuttles: The shuttles are autonomous or semi-autonomous vehicles that move horizontally along predefined tracks or lanes within the warehouse. They are designed to carry goods, such as pallets or bins, and transport them between different storage locations or workstations.

2. Track or Guideway System: The shuttle transporter operates on a dedicated track or guideway system within the warehouse. This system can be installed on the floor or integrated into the warehouse racking structure, providing a designated path for the shuttles to follow.

3. Central Control System: The shuttle transporter system is controlled and coordinated by a central control system. This system manages the movement and routing of the shuttles, ensuring efficient and effective transportation of goods within the warehouse.

4. Loading and Unloading Stations: The warehouse shuttle transporter typically has designated loading and unloading stations where goods can be loaded onto or unloaded from the shuttles. These stations can be manned by operators or integrated with other automated systems, such as conveyor belts or robotic arms, for seamless material transfer.

The benefits of a warehouse shuttle transporter system include:

1. Increased Efficiency: The automated or semi-automated nature of the system allows for faster and more efficient movement of goods within the warehouse. It reduces the reliance on manual labor and minimizes the time required for goods transportation.

2. Space Optimization: Warehouse shuttle transporters can be designed to operate in high-density storage environments, such as rack-supported structures or automated storage and retrieval systems (AS/RS). This allows for better utilization of vertical and horizontal space within the warehouse.

3. Flexibility and Scalability: The system can be configured and scaled to adapt to changing operational requirements. Additional shuttles and track sections can be added as the warehouse expands or the storage needs evolve.

4. Improved Inventory Management: With a shuttle transporter system, goods can be tracked and managed more effectively. The central control system can provide real-time information on inventory locations, quantities, and movements, enabling better inventory control and order fulfillment.