Products

Ebil Tech

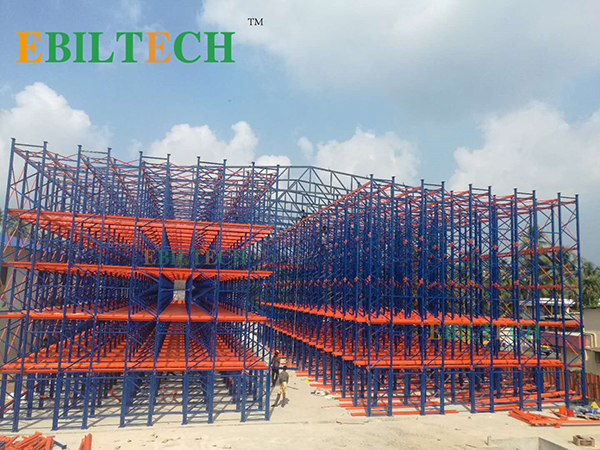

VNA Pallet Racking System

VNA Pallet Racking System is one of our products, we can provide one-stop storage system solutions and products, our products also include ASRS Rack, Automatic Pallet Rack, Telescopic arm storage rack, VNA Storage Rack, Shuttle Storage System, Teardrop Pallet Rack System, Medium-Duty Warehouse Rack, Four-Directional Shuttle Car, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Indianapolis (United States), Nantes (France), Montpellier (France), Sana'a (Yemen), AbuMusa, North Ossetia, and so on. We are looking forward to cooperate with you. If you are interested in VNA Pallet Racking System.

VNA Pallet Racking System, also known as Very Narrow Aisle Pallet Racking System, is a type of storage system designed to maximize warehouse space utilization by reducing the aisle width between racks. It is commonly used in warehouses where space is limited, and high-density storage is required.

Key features of VNA Pallet Racking System include:

1. Narrow Aisles: VNA racking systems utilize narrow aisles between the racks, typically ranging from 1.6 to 2.4 meters (5 to 8 feet) in width. By minimizing the aisle width, more storage space can be allocated within the warehouse.

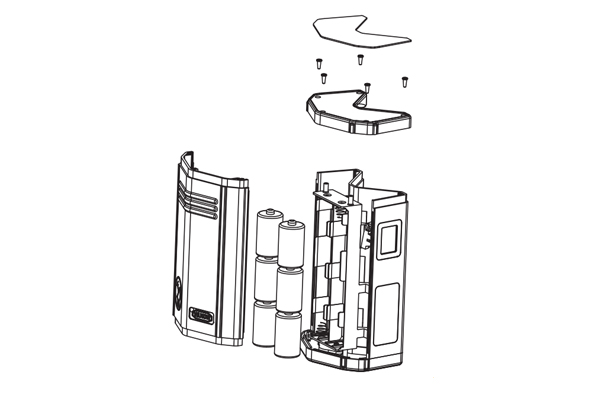

2. Specialized Forklifts: VNA racking systems require specialized forklifts with narrow and articulated design. These forklifts can navigate the narrow aisles and have the ability to rotate the forks to pick up or place pallets from both sides of the aisle.

3. High Racking Heights: VNA racking systems are designed to accommodate high racking heights, taking advantage of vertical space. They often have taller upright frames and utilize the full height of the warehouse, allowing for increased storage capacity.

4. Guide Rails or Wire Guidance Systems: To ensure precise movement of the forklifts within the narrow aisles, VNA systems often incorporate guide rails or wire guidance systems. These guide the forklifts along the aisles, minimizing the risk of collisions and ensuring accurate positioning.

Benefits of VNA Pallet Racking System:

1. Increased Storage Capacity: VNA racking systems maximize the use of available vertical space, allowing for higher storage density compared to conventional pallet racking systems. This is particularly beneficial in warehouses with limited floor space.

2. Improved Space Efficiency: By reducing the aisle width, VNA systems can utilize more floor space for storage, resulting in a higher storage density. This can lead to significant cost savings in terms of reduced warehouse footprint or the ability to store more inventory.

3. Selectivity: Despite the narrow aisles, VNA systems still provide selective access to each pallet. Forklifts can retrieve any pallet from any location within the system, providing flexibility in inventory management and order picking.

4. Enhanced Inventory Control: VNA racking systems are often integrated with Warehouse Management Systems (WMS) or inventory management software. This allows for real-time inventory tracking, accurate stock management, and efficient order fulfillment.

It's important to note that VNA Pallet Racking Systems require careful planning and consideration of warehouse layout, forklift requirements, and operational needs. The implementation of these systems often involves significant upfront investment due to specialized equipment and infrastructure requirements.