Products

Ebil Tech

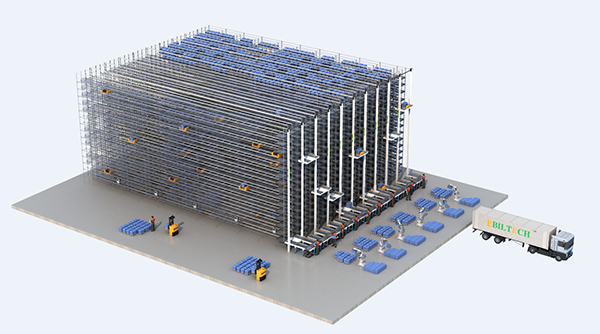

Multi Shuttle

Multi Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Steel Racking, Mezzanine Racking System, Cold Chain Storage Rack, Four-Way Shuttle Racking System, Metal Racking, A-Type Medium Rack, Multi Level Shuttle, Teardrop Warehouse Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Edinburgh (Scotland, UK), Palau, Korea, South, Tunis City (Tunisia), Dortmund (Germany), Grenada, and so on. We are looking forward to cooperate with you. If you are interested in Multi Shuttle.

The Multi Shuttle is a system or equipment that involves multiple shuttle units working together for efficient storage and retrieval of goods in a warehouse or distribution center.

In such a system, multiple shuttle units, also known as autonomous or automated guided vehicles (AGVs), are utilized to handle and transport goods within the facility. These shuttle units can operate independently or in coordination with each other to optimize material flow and improve operational efficiency.

Here are some possible characteristics of a Multi Shuttle system:

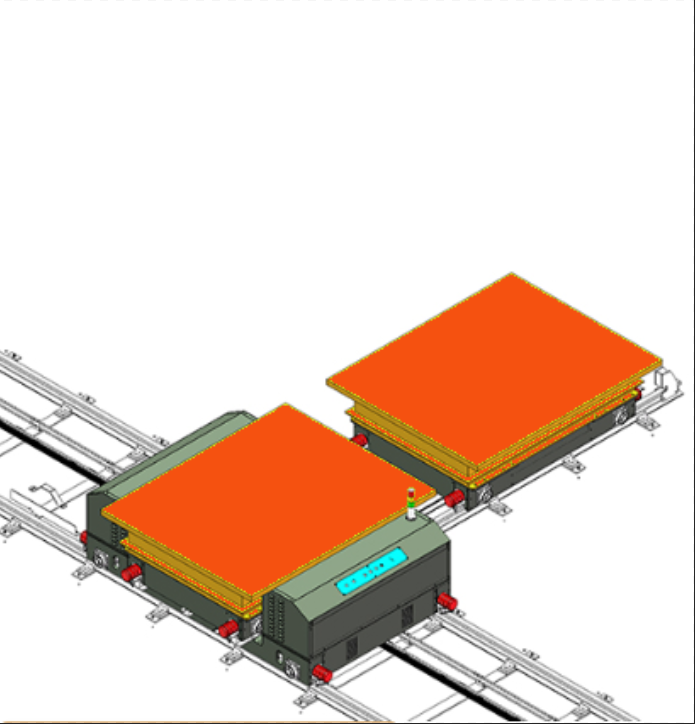

1. Multiple Shuttle Units: The system includes multiple shuttle units, which can be vehicles with wheels or platforms. These units are designed to navigate the facility autonomously or under centralized control.

2. Storage and Retrieval: Each shuttle unit is responsible for the storage and retrieval of goods. They can transport goods to and from storage locations, such as racks, shelves, or conveyors, within the facility.

3. Coordination and Communication: The shuttle units may be coordinated and communicate with each other and a central control system. This coordination allows for efficient task allocation, route optimization, and real-time status updates.

4. Automation and Integration: Multi Shuttle systems often involve automation and integration with other systems within the facility, such as warehouse management systems (WMS), inventory control systems, or conveyor systems. This integration enables seamless coordination and information exchange between various components.

5. Space Optimization: The use of multiple shuttle units allows for efficient space utilization. They can access goods stored in different levels or areas of the warehouse, maximizing the storage capacity.

It's worth noting that the specific features, capabilities, and configurations of a Multi Shuttle system may vary depending on the manufacturer, application, and specific requirements of the facility.