Benefits of Mother and Child Shuttle systems, and it's price

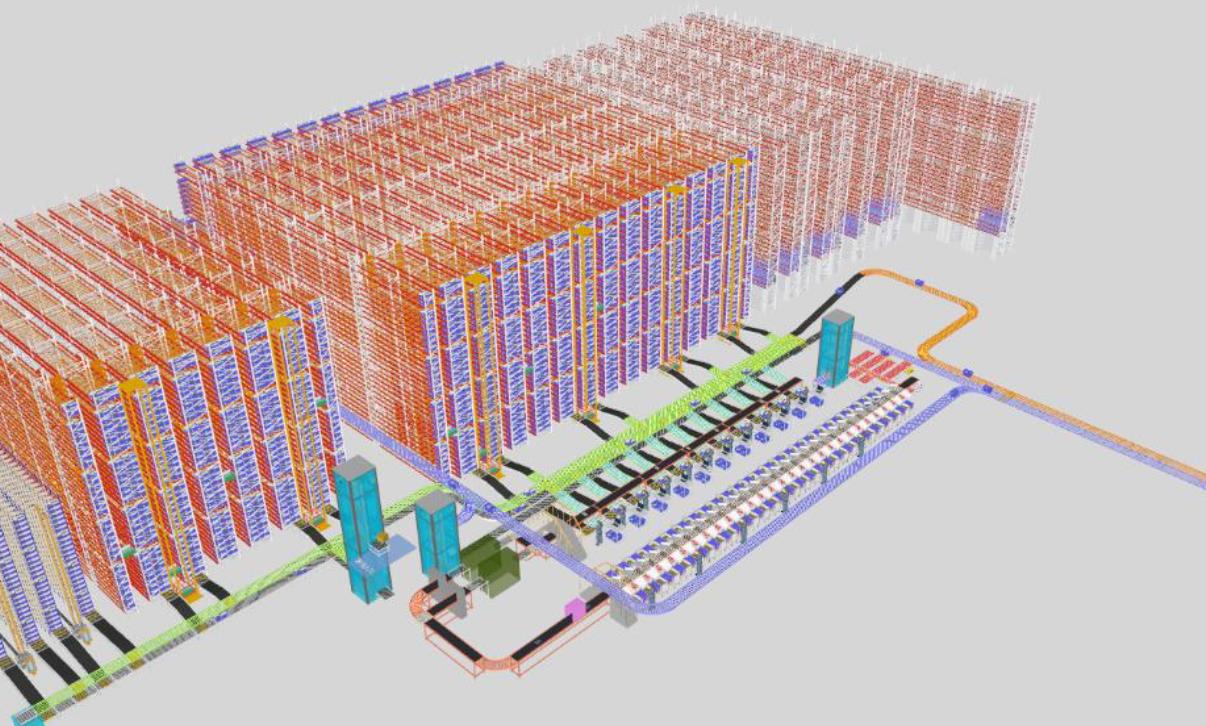

The term "Mother and Child Shuttle" refers to a type of automated storage and retrieval system (AS/RS) commonly used in warehousing and distribution centers. It consists of two components: the "mother" shuttle and the "child" shuttle.

The mother shuttle is a larger automated vehicle that moves horizontally along a track system installed between storage racks. It carries multiple child shuttles, which are smaller automated vehicles that travel vertically within the storage racks, accessing individual storage locations.

How the Mother and Child Shuttle system typically operates:

1. Storage Racks: The storage area is equipped with tall racks, divided into multiple levels or tiers, with storage positions for pallets or bins.

2. Mother Shuttle: The mother shuttle moves horizontally along the track system positioned between the racks. It carries one or more child shuttles on board.

3. Child Shuttles: The child shuttles are responsible for vertical movement within the racks. They travel along the rack structure and access individual storage positions.

4. Retrieval and Storage: When a specific item needs to be retrieved or stored, the mother shuttle positions itself adjacent to the relevant storage rack. The child shuttle carrying the required item moves vertically to the desired level and location within the rack.

5. Transfer: Once the child shuttle has reached the appropriate storage position, it transfers the item (pallet, bin, or other container) to or from the storage location.

6. Communication and Control: The mother and child shuttles are controlled by a central control system, which receives instructions for item retrieval or storage. The control system coordinates the movement of the shuttles, ensuring efficient and accurate storage and retrieval operations.

Benefits of Mother and Child Shuttle systems include:

1. Space Optimization: The vertical movement of child shuttles within the racks allows for high-density storage, maximizing the use of available space.

2. Increased Throughput: The use of multiple child shuttles enables simultaneous storage and retrieval operations, leading to higher operational efficiency and throughput.

3. Flexibility: Mother and Child Shuttle systems can be customized and scaled to fit specific storage requirements. They can accommodate different pallet sizes and adapt to changing storage needs.

4. Automation and Efficiency: The automated nature of the system reduces manual labor and streamlines storage and retrieval processes, resulting in improved efficiency and reduced operational costs.

Mother and Child Shuttle systems are commonly employed in industries such as logistics, e-commerce, manufacturing, and distribution centers where high-density storage and efficient retrieval of goods are critical.

Price of a Mother and Child Shuttle

The cost of a Mother and Child Shuttle system can vary depending on several factors, including the size of the system, the number of shuttles, the complexity of the installation, customization requirements, and the specific supplier or manufacturer. Here are some general considerations when it comes to pricing:

1. System Size: The size of the system, including the number of storage racks, levels, and storage positions, will affect the overall cost. Larger systems with more extensive storage capacities will generally be more expensive.

2. Number of Shuttles: The cost of the Mother and Child Shuttle system will be influenced by the number of child shuttles required to handle the storage and retrieval tasks efficiently. Additional shuttles will increase the overall cost.

3. Customization and Features: Customization options, such as specific rack configurations, safety features, automation capabilities, and integration with control systems, can impact the cost. More complex or customized systems will usually come with a higher price tag.

4. Installation and Integration: The installation process and integration of the Mother and Child Shuttle system with existing infrastructure, such as conveyor systems or warehouse management systems, may require additional expenses for professional services and customization.

5. Maintenance and Service: Ongoing maintenance and service costs should also be considered. These costs can vary depending on the supplier's recommended maintenance schedule, availability of spare parts, and any service agreements or warranties provided.

Here are some rough price examples to give you a general idea of the cost range for a Mother and Child Shuttle system. Please note that these prices are approximate and can vary based on factors such as system size, customization, supplier, and location:

1. Small-Scale System: A small Mother and Child Shuttle system with a limited number of storage racks, a single mother shuttle, and a few child shuttles can start at around $100,000 to $200,000.

2. Medium-Sized System: A medium-sized system with a higher number of storage racks, multiple mother shuttles, and a larger fleet of child shuttles can range from $300,000 to $500,000.

3. Large-Scale System: A large-scale Mother and Child Shuttle system designed for a spacious warehouse, featuring extensive customization options, advanced automation capabilities, and integration with control systems, can cost upwards of $1 million or more.

4. High-Capacity System: Mother and Child Shuttle systems with high storage capacities, capable of handling a large number of pallets or bins, can have higher price points. These systems can range from $500,000 to several million dollars, depending on the specific requirements.

Due to the varying nature of system requirements and customization options, it is challenging to provide a specific price range for a Mother and Child Shuttle system. It is recommended to reach out to suppliers or manufacturers specializing in automated storage and retrieval systems to discuss your specific needs and obtain accurate price quotations based on your requirements. They can provide detailed cost estimates, taking into account factors such as system size, customization, and installation considerations.