Products

Ebil Tech

Shuttle Carrier

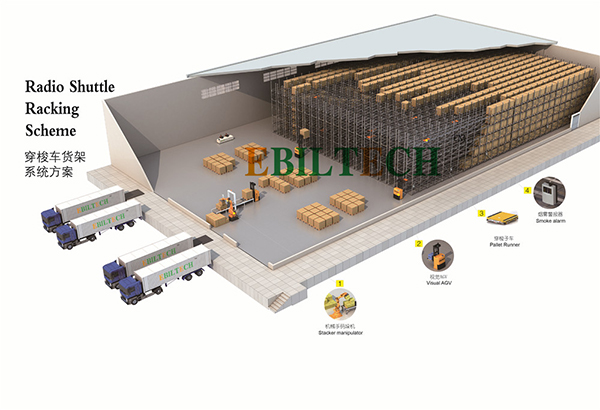

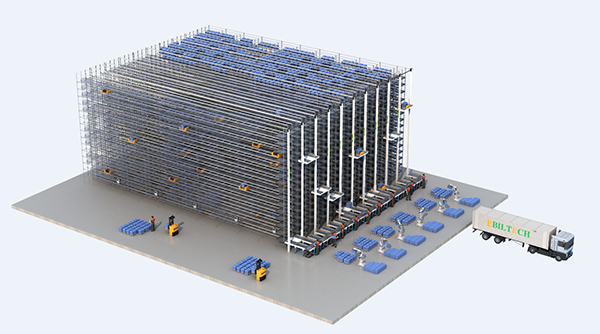

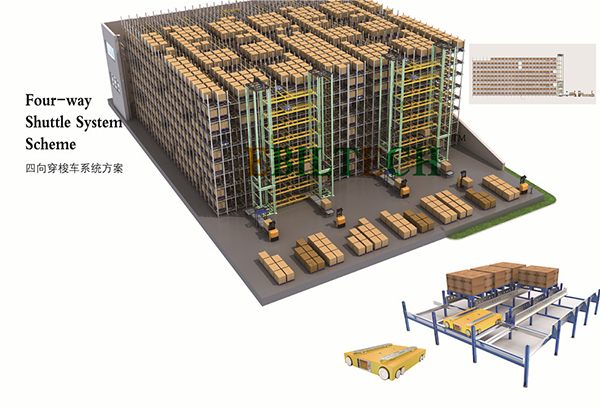

Shuttle Carrier is one of our products, we can provide one-stop storage system solutions and products, our products also include Powered Mobile Racking, Omni-Directional Shuttle Car, Bars and Tubes Storage Systems, Steel Mezzanine Rack, Pallet Flow Racking System, Steel Storage Platform, Intelligent Stacker Crane, Warehouse Pallet Racking, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Guatemala City (Guatemala), Dominican Republic, Mumbai (Maharashtra, India), Singapore (Singapore), Sydney (New South Wales, Australia), Estonia, and so on. We are looking forward to cooperate with you. If you are interested in Shuttle Carrier.

Here are some key features and characteristics of a storage Shuttle Carrier:

1. Automated Operation: The storage Shuttle Carrier operates autonomously, guided by a central control system or warehouse management system (WMS). It receives instructions from the control system to perform specific storage and retrieval tasks.

2. Container or Pallet Handling: The Shuttle Carrier is equipped with mechanisms, such as forks, clamps, or conveyors, to securely hold and transport storage containers, bins, or pallets. It can lift, move, and position these units as per the requirements of the warehouse operations.

3. Horizontal and Vertical Movement: The Shuttle Carrier can move horizontally within the warehouse aisles or storage areas to access different locations. Depending on the system design, it may also have the capability to move vertically, accessing multiple levels of storage within a high-rise racking system.

4. Guided Navigation: The Shuttle Carrier typically operates on a predefined path or track system within the warehouse. It may utilize sensors, markers, or navigation technologies such as optical guidance or magnetic induction to follow the designated routes accurately.

5. Integration with Storage Systems: The storage Shuttle Carrier is often designed to work in conjunction with specific storage systems, such as automated storage and retrieval systems (AS/RS), pallet racking, or shelving systems. It seamlessly interfaces with these storage systems to facilitate the movement of storage units.

6. Scalability and Flexibility: The Shuttle Carrier system can be scalable and adaptable to varying warehouse sizes and configurations. It can be customized to handle different types and sizes of storage containers or pallets, accommodating the specific needs of the warehouse operations.

7. Improved Efficiency: The use of a storage Shuttle Carrier system enhances operational efficiency by reducing manual labor requirements, increasing the speed and accuracy of storage and retrieval operations, and optimizing the utilization of warehouse space.

It's worth noting that the specific features, capabilities, and configurations of a storage Shuttle Carrier system can vary depending on the manufacturer and the requirements of the warehouse or distribution center it is designed for.