Products

Ebil Tech

Automated Storage for Sheet

Automated Storage for Sheet is one of our products, we can provide one-stop storage system solutions and products, our products also include Mezzanine Steel Rack, Cold Storage Rack, Storage Rack, Automatic Stacker, Drive In Pallet Rack, Warehouse Robot, Teardrop Style Rack, Tight Aisle Pallet Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Somaliland, Cairo (Egypt), Port of Spain (Trinidad and Tobago), French Polynesia, Andorra, Uzbekistan, and so on. We are looking forward to cooperate with you. If you are interested in Automated Storage for Sheet.

Automated storage systems for sheets, such as metal sheets or other flat materials, are designed to efficiently store and retrieve these items in a controlled and automated manner. There are several types of automated storage solutions available for sheet materials. Here are some common examples:

1. Vertical Sheet Storage Systems: Vertical sheet storage systems utilize vertical space to maximize storage capacity. These systems typically consist of vertical racks or towers with multiple storage compartments or drawers. The sheets are loaded into the drawers, and an automated system retrieves and delivers the desired sheet to the operator. This type of system is suitable for storing sheets of varying sizes and thicknesses.

2. Horizontal Sheet Storage Systems: Horizontal sheet storage systems are designed for large-format sheets or panels. These systems typically feature shelves or trays that can hold multiple sheets side by side. The automated system moves along the storage rows and retrieves the desired sheet when needed. It is an efficient solution for high-volume sheet storage.

3. Robotic Sheet Handling Systems: Robotic systems can be used for automated sheet storage and retrieval. Robots equipped with specialized grippers or suction cups can handle sheets of various sizes and weights. These systems can be integrated with other automation technologies to provide a complete end-to-end solution for sheet material handling.

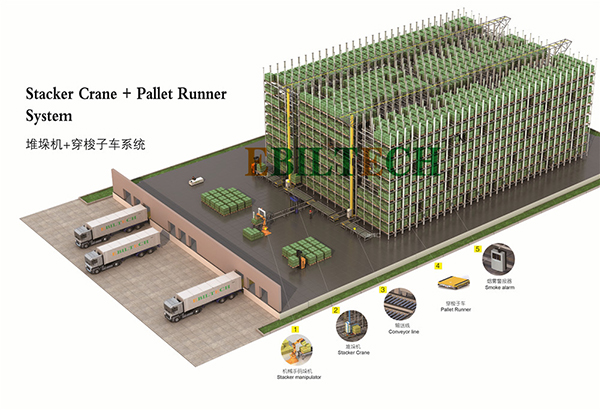

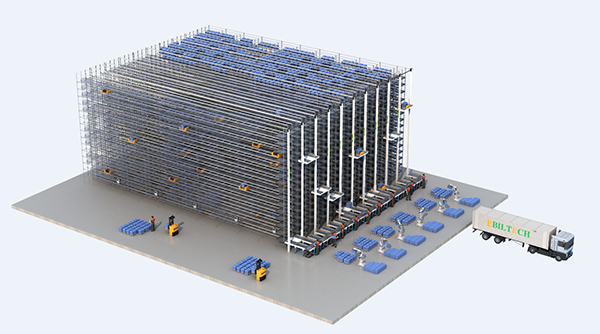

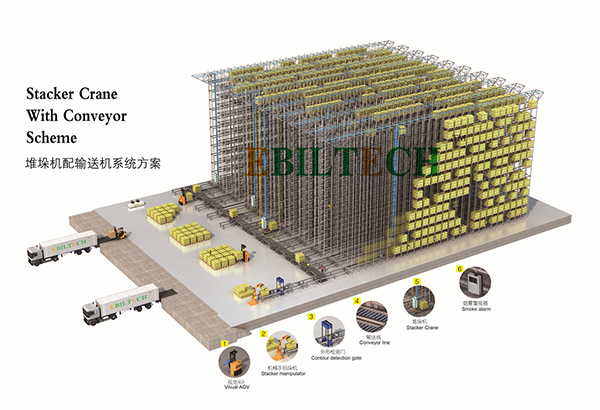

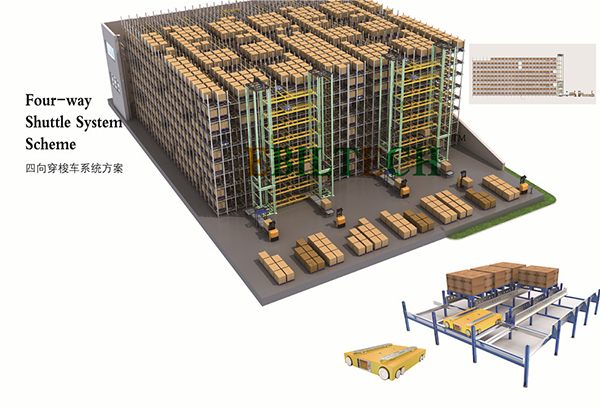

4. AS/RS (Automated Storage and Retrieval Systems): AS/RS systems are highly automated and versatile storage solutions that can be customized for sheet storage. They typically consist of a combination of racks, conveyors, shuttles, and robotic arms. AS/RS systems offer high-density storage, fast retrieval times, and can be integrated with other manufacturing or logistics processes.

5. Software and Control Systems: Automated sheet storage systems are often equipped with software and control systems that manage inventory, track sheet locations, and optimize storage space utilization. These systems can integrate with warehouse management systems (WMS) or enterprise resource planning (ERP) systems to provide seamless material flow and inventory management.

6. Integration with Cutting or Fabrication Equipment: Automated sheet storage systems can be seamlessly integrated with cutting or fabrication equipment, such as laser cutters or CNC machines. This integration enables a streamlined workflow, where sheets are automatically retrieved from storage and fed into the processing equipment, minimizing manual handling and improving efficiency.

7. Inventory Tracking and Management: Automated storage systems for sheets often include inventory tracking and management features. Barcode or RFID technology can be used to track sheet movements, monitor stock levels, and facilitate accurate inventory management. This helps ensure efficient material flow and minimizes the risk of stockouts or overstocking.

8. Safety Features: Safety is a crucial consideration in automated storage systems. Proximity sensors, safety scanners, or light curtains can be integrated into the system to detect the presence of personnel or obstacles in the vicinity of the automated equipment. This helps prevent accidents and ensures a safe working environment.

9. Scalability and Flexibility: Automated sheet storage systems are designed to be scalable and flexible to accommodate changing storage needs. They can be expanded or reconfigured as required, allowing for future growth or modifications to the storage layout.

10. Return on Investment (ROI): Investing in an automated storage system for sheets can provide a significant return on investment. By optimizing storage space, reducing material handling time, minimizing errors, and improving overall efficiency, these systems can help lower operational costs, increase productivity, and enhance customer satisfaction.

It's important to work with experienced suppliers or manufacturers of automated storage systems for sheet materials. They can provide comprehensive solutions tailored to your specific requirements, assist in system design and layout, and offer support throughout the implementation process. They will also be able to provide accurate pricing based on the size and complexity of the system you need.

Features of automated storage systems for sheets

Automated storage systems for sheets come with various features and capabilities designed to optimize sheet handling, storage efficiency, and overall productivity. Here are some common features you can find in these systems:

1. High-Density Storage: Automated storage systems for sheets are designed to maximize storage capacity by utilizing vertical space or compact storage configurations. They offer high-density storage solutions to accommodate a large number of sheets within a limited footprint.

2. Customizable Storage Compartments: The storage compartments or drawers within the system can be customized to accommodate sheets of different sizes, weights, and material types. This flexibility allows for efficient storage and retrieval of sheets with varying specifications.

3. Automated Retrieval and Delivery: These systems automate the process of retrieving and delivering sheets to the operator or downstream processing equipment. Robotic arms, conveyors, shuttles, or other automated mechanisms are employed to handle sheet movements, reducing manual labor and improving efficiency.

4. Inventory Management and Tracking: Automated storage systems incorporate inventory management features to track sheet locations, quantities, and other relevant information. Barcode or RFID technology is often used to ensure accurate inventory tracking, enabling real-time visibility of sheet inventory levels and facilitating efficient material flow.

5. Integration with Cutting/Fabrication Equipment: Many automated sheet storage systems can be seamlessly integrated with cutting or fabrication equipment, such as laser cutters or CNC machines. This integration enables a streamlined workflow where sheets are automatically retrieved from storage and fed into the processing equipment, minimizing manual handling and improving production efficiency.

6. Safety Features: Safety is a critical consideration in automated storage systems. These systems often include safety features such as proximity sensors, safety scanners, or light curtains to detect the presence of personnel or obstacles in the vicinity of the automated equipment. This helps prevent accidents and ensures a safe working environment.

7. Software Control and Integration: Automated sheet storage systems are typically equipped with software control systems that manage and optimize sheet storage operations. These systems can integrate with warehouse management systems (WMS) or enterprise resource planning (ERP) systems to provide seamless data exchange, real-time monitoring, and efficient material handling.

8. Scalability and Expandability: Automated storage systems for sheets are designed to be scalable and expandable to accommodate changing storage needs. They can be easily expanded or reconfigured to adapt to future growth or changes in sheet storage requirements.

These features contribute to improved efficiency, reduced labor costs, enhanced inventory control, and optimized material flow in sheet handling and storage processes. The specific features and capabilities may vary depending on the manufacturer and the type of automated storage system you choose.

Cost of automated storage systems for sheets

The cost of automated storage systems for sheets can vary significantly based on several factors, including the specific type of system, system capacity, level of automation, customization, supplier, and location. It is important to note that providing an exact cost without specific project details is challenging.

As a rough estimate, automated storage systems for sheets can range from tens of thousands of dollars to several hundred thousand dollars or more, depending on the complexity and scale of the system. Here are some cost considerations:

1. System Type: The type of automated storage system selected will affect the cost. Vertical sheet storage systems, horizontal sheet storage systems, robotic handling systems, or AS/RS systems have different price ranges based on their design, features, and capabilities.

2. System Capacity: The size and capacity of the system will impact the cost. Larger systems capable of storing a higher volume of sheets will generally cost more compared to smaller-scale systems.

3. Level of Automation: The level of automation desired, including the number of robotic arms, conveyors, shuttles, or other automated components, will influence the cost. More advanced automation features will typically increase the overall price.

4. Customization: Customization requirements, such as specialized grippers, tailored software integration, or specific layout configurations, can add to the cost of the system. Customized solutions are typically more expensive than standard configurations.

5. Supplier and Location: Different suppliers or manufacturers may have varying pricing structures and cost considerations. Additionally, factors such as shipping, installation, and local market conditions can impact the overall price.

Here are some examples of the cost range for automated storage systems for sheets:

1. Basic Vertical Sheet Storage System: A small-scale vertical sheet storage system with a moderate capacity and basic automation features can range from $30,000 to $50,000.

2. Medium-Sized Horizontal Sheet Storage System: A horizontal sheet storage system with higher capacity and more advanced automation capabilities can range from $70,000 to $150,000.

3. Robotic Sheet Handling System: A robotic sheet handling system with multiple robotic arms, integrated conveyors, and advanced software integration can range from $100,000 to $300,000 or more, depending on the complexity and customization required.

4. AS/RS System: An AS/RS system for sheet storage, featuring high-density storage, automated retrieval, and integration with cutting or fabrication equipment, can range from $200,000 to $500,000 or higher, depending on the system size and customization.

It's important to note that these are general price ranges and can vary significantly based on factors such as system size, capacity, level of automation, customization, and supplier pricing policies. Obtaining detailed quotes from suppliers or manufacturers specializing in automated storage solutions for sheets will provide a more accurate understanding of the costs associated with your specific project requirements. They can provide detailed cost estimates and help you determine the most suitable solution for your sheet storage needs.