Products

Ebil Tech

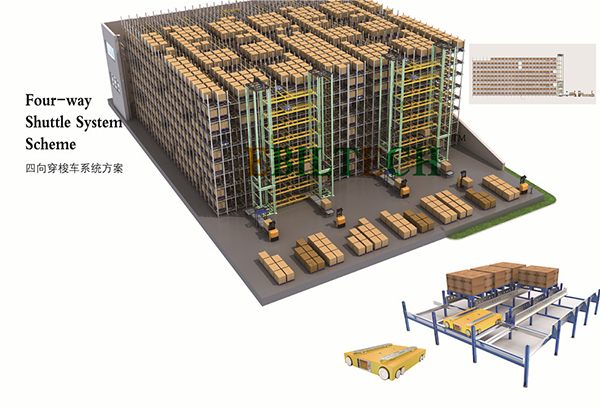

4 Way Shuttle

4 Way Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Teardrop Pallet Racking, A-Type Medium Rack, Drive In Racking, Shuttle Robot Rack, Mezzanine Floor Rack, Beam Rack System, Garment Storage Shelving, Adjustable Arm Cantilever Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Bahrain, Bratislava (Slovakia), Mexicali (Mexico), Podgorica (Montenegro), Philadelphia (Pennsylvania, USA), Haiti, and so on. We are looking forward to cooperate with you. If you are interested in 4 Way Shuttle.

The 4 Way Shuttle typically refers to a type of material handling equipment used in warehouses or distribution centers for the storage and retrieval of goods. It is designed to move horizontally and vertically within a racking system, providing flexibility and efficient utilization of storage space.

The key features and functions of a 4 Way Shuttle include:

1. Horizontal and Vertical Movement: The 4 Way Shuttle can move horizontally along the length of the storage lanes, similar to a traditional shuttle system. Additionally, it has the capability to move vertically, allowing it to access different levels or tiers within the racking system.

2. Four-Way Directional Movement: Unlike standard shuttle systems that typically move in a single direction along the storage lanes, a 4 Way Shuttle has the ability to move in four directions: forward, backward, left, and right. This flexibility enables it to access any position within the storage system, maximizing storage capacity and accessibility.

3. Load Handling: The 4 Way Shuttle is designed to handle pallets or other unit loads. It is equipped with forks or platforms that can support and transport the loads within the storage lanes.

4. Automation and Control: The operation of the 4 Way Shuttle is typically automated and controlled by a central computerized system. It receives commands from the warehouse management system (WMS) to retrieve or store specific loads at designated locations.

5. High-Density Storage: The 4 Way Shuttle system enables high-density storage by utilizing both the horizontal and vertical space within the racking system. It can access and store goods at various levels, optimizing storage capacity and reducing the footprint required.

6. Improved Efficiency: The 4 Way Shuttle system enhances material handling efficiency by streamlining the storage and retrieval processes. It can quickly and accurately position loads within the racking system, facilitating faster order fulfillment and inventory management.

The 4 Way Shuttle is particularly suitable for warehouses or distribution centers that require efficient utilization of storage space, high-density storage, and easy access to loads from various directions. It offers flexibility, versatility, and increased productivity in material handling operations.