Products

Ebil Tech

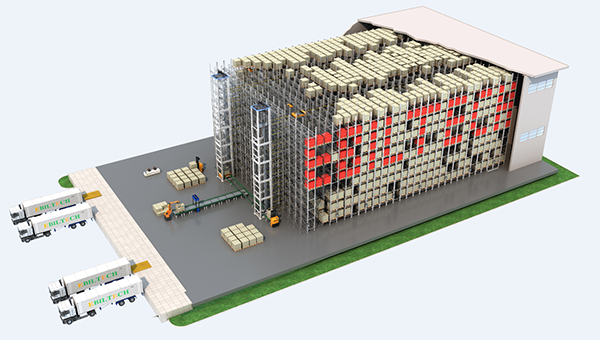

Automatic Shuttle Carrier

Automatic Shuttle Carrier is one of our products, we can provide one-stop storage system solutions and products, our products also include Automatic Pallet Rack, Selective Rack, Honeycomb Rack Starr, Teardrop Style Rack, Steel Racking, Medium-Duty Shelving Unit, Automated Warehouse Rack, Automatic Stacker Crane, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Sao Paulo (Sao Paulo State, Brazil), Saint Pierre and Miquelon, Accra (Ghana), Czech Republic, Liberia, Sierra Leone, and so on. We are looking forward to cooperate with you. If you are interested in Automatic Shuttle Carrier.

An Automatic Shuttle Carrier, also known as an Automated Shuttle System or Shuttle Robot, is a type of material handling equipment used for automated storage and retrieval of goods in a warehouse or distribution center. It is designed to transport and position loads, such as bins, totes, or cartons, within a racking system.

The features and characteristics of an Automatic Shuttle Carrier:

1. Autonomous Operation: An Automatic Shuttle Carrier operates autonomously or under centralized control. It can navigate through the racking system, retrieve or store goods, and move between different storage positions without constant human intervention.

2. Shuttle Platform: The carrier typically consists of a platform that can move horizontally along the racking structure. It is equipped with wheels or rollers to facilitate smooth movement along the designated paths.

3. Load Handling: Automatic Shuttle Carriers are designed to handle different types of loads. They can lift, lower, and transport bins, totes, or cartons within the racking system. Some models may also have mechanisms to rotate or tilt the loads for optimal positioning.

4. Communication and Integration: Automatic Shuttle Carriers communicate with a central control system or warehouse management system (WMS). They receive instructions, provide real-time status updates, and integrate with other equipment or systems within the facility for efficient material flow and coordination.

5. Energy Supply: Automatic Shuttle Carriers are powered by rechargeable batteries or other energy sources. They can autonomously navigate to charging stations when their battery levels are low, ensuring uninterrupted operation.

6. Safety Features: Safety is a critical aspect of Automatic Shuttle Carriers. They are equipped with safety sensors, collision avoidance mechanisms, emergency stop buttons, and safety protocols to prevent accidents and ensure the safety of humans and goods in their vicinity.

Automatic Shuttle Carriers offer benefits such as increased storage density, improved picking efficiency, and reduced labor requirements in warehouse operations. They optimize space utilization, streamline material flow, and enable faster storage and retrieval of goods.

The specific features, capacities, and designs of Automatic Shuttle Carriers may vary among manufacturers and depend on the particular requirements and layout of the racking system.