Products

Ebil Tech

Pallet Runner

Pallet Runner is one of our products, we can provide one-stop storage system solutions and products, our products also include Medium-Duty Pallet Rack, Gravity Pallet Racking, Storage Laneway Shuttle, Pallet Flow Shelving, High-Density Storage Rack, Beam Racking System, Freezer Warehouse Rack, Telescoping beam rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Cleveland (United States), Malawi, Philippines, Tashkent (Uzbekistan), Japan, Bermuda, and so on. We are looking forward to cooperate with you. If you are interested in Pallet Runner.

Pallet Runner, also known as a Pallet Runner System or Pallet Runner Shuttle, is an automated storage and retrieval system (AS/RS) used for high-density pallet storage in warehouses and distribution centers. It is designed to optimize space utilization and improve efficiency in pallet handling operations.

Pallet Runner systems provide benefits such as increased storage capacity, improved throughput, reduced labor requirements, and enhanced inventory control. They are particularly useful in operations with a large number of pallets and a need for high selectivity and efficient space utilization.

The specific design and capabilities of a Pallet Runner system may vary depending on the manufacturer or system provider. Different companies may have their own proprietary technologies, variations, or alternative names for similar systems.

Here are the key features and components of a Pallet Runner system:

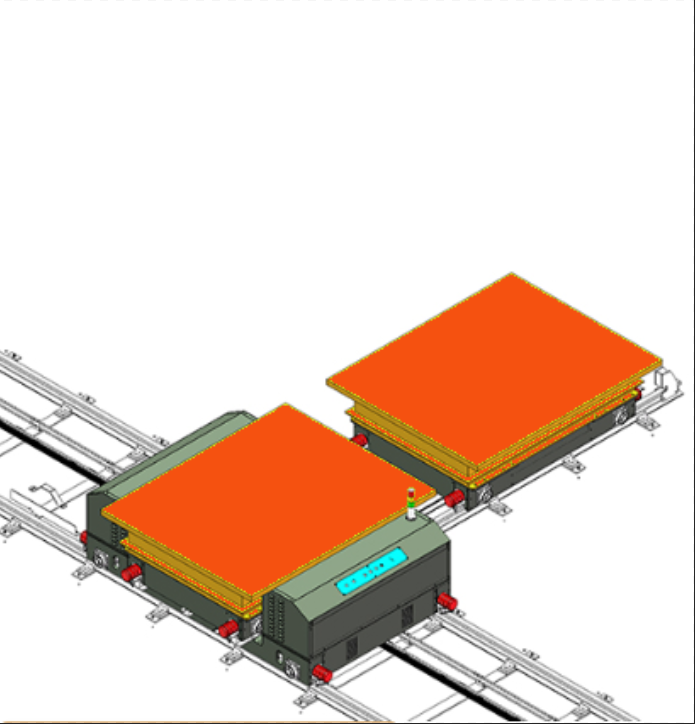

1. Shuttle Vehicle: The Pallet Runner system consists of a shuttle vehicle that operates within the storage lanes of a racking structure. The shuttle is a motorized device that can move horizontally along the depth of the rack, carrying and retrieving pallets.

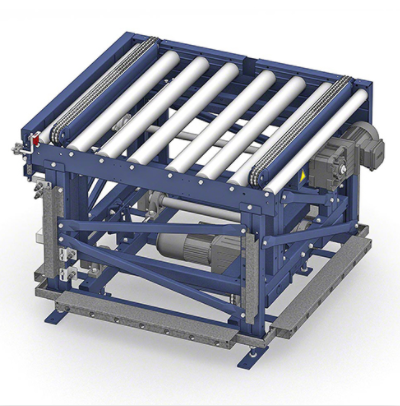

2. Racking Structure: The racking structure of a Pallet Runner system typically consists of deep storage lanes where the shuttle vehicle can operate. The lanes are designed to accommodate multiple pallets in a depth-wise configuration, allowing for high-density storage.

3. Pallet Storage and Retrieval: Pallets are loaded into the storage lanes by forklifts or other equipment at the entry points. The shuttle vehicle is then used to transport the pallets within the lane to the desired storage location or retrieval point. It can move pallets forward or backward within the lane, stacking and retrieving them as needed.

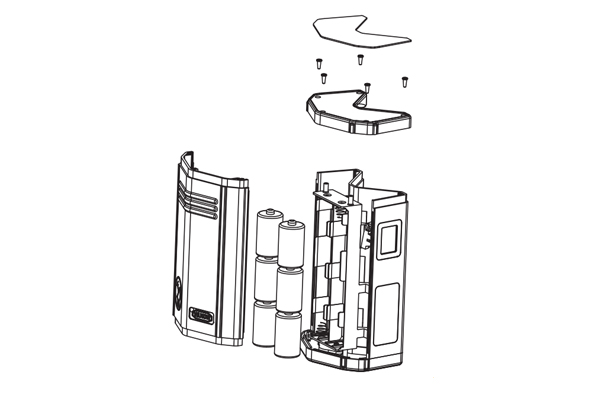

4. Remote Control and Communication: The shuttle vehicle is controlled remotely using a handheld remote control or a centralized control system. Operators send commands to the shuttle to perform tasks such as loading, unloading, and moving pallets within the storage lanes. Communication between the control system and the shuttle vehicle is typically wireless, usually utilizing radio frequency (RF) technology.

5. Software Control and Integration: The Pallet Runner system is integrated with software control systems or warehouse management systems (WMS). This integration allows for seamless coordination, task assignment, and real-time monitoring of the shuttle vehicles' operations. It also enables optimization of material flow, inventory management, and reporting functions.

6. High-Density Storage and Selectivity: Pallet Runner systems offer high-density storage capabilities, as multiple pallets can be stored in a single lane. This allows for efficient use of warehouse space while maintaining selectivity, as each lane can be accessed independently. This makes it suitable for applications where a high volume of pallets needs to be stored and retrieved regularly.