Products

Ebil Tech

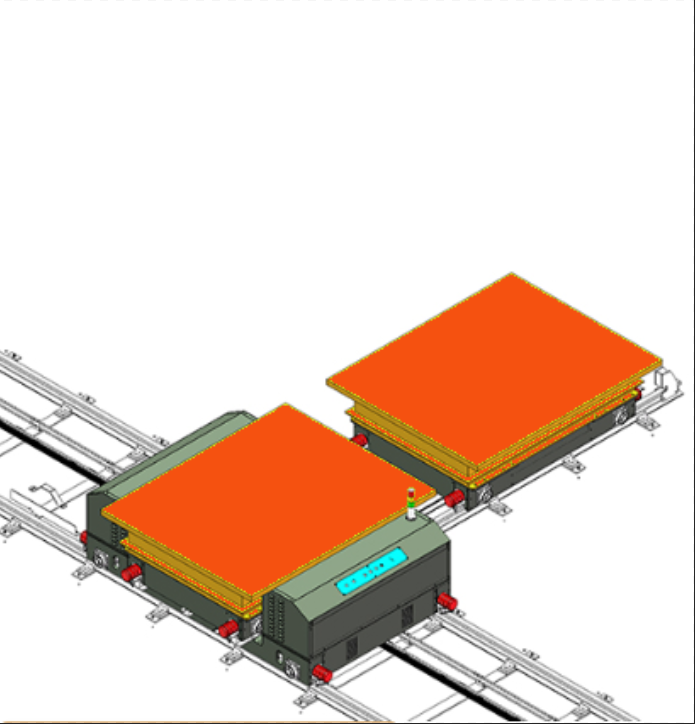

Smart Pallet Shuttle

Smart Pallet Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Four-Way Forklift, Industrial Shuttle Car, Vertical Lift, Robotic Shuttle, Teardrop Style Rack, Multi-Level Steel Mezzanine Racking, Beam Rack, Electric extendable cantilever shelving, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Brunei, Des Moines (United States), Graz (Austria), Nauru, Islamabad/Islamabad (Pakistan), Cape Verde, and so on. We are looking forward to cooperate with you. If you are interested in Smart Pallet Shuttle.

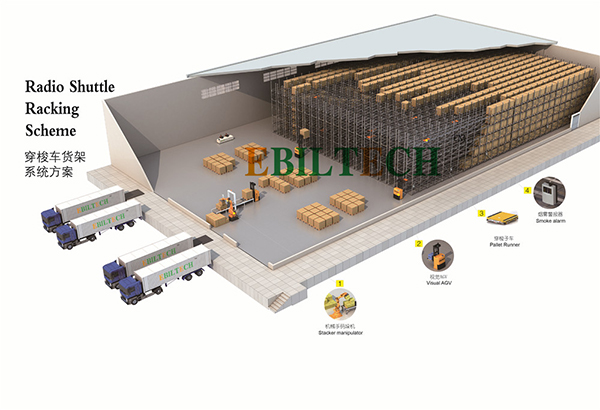

The Smart Pallet Shuttle refers to an automated material handling system designed to optimize and streamline the storage and retrieval of palletized goods within a warehouse or distribution center. The Smart Pallet Shuttle system is specifically designed to work with pallets, which are commonly used in industries for storing and transporting large quantities of goods.

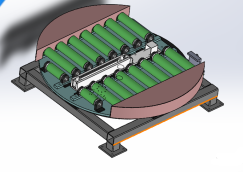

The Smart Pallet Shuttle system typically consists of shuttle robots or devices that operate within a channel or lane system built into the pallet racking structure. These shuttles are responsible for handling and transporting pallets within the racking system, eliminating the need for forklifts or manual labor to move pallets.

The Smart Pallet Shuttle system offers numerous benefits, including increased storage capacity, improved inventory control, reduced labor costs, and enhanced operational efficiency in palletized goods handling within a warehouse or distribution center.

The key features and functionalities of a Smart Pallet Shuttle system:

1. Automated Pallet Handling: The Smart Pallet Shuttle system automates the storage and retrieval of pallets. The shuttles can be programmed to move along the channels or lanes, carrying pallets to the designated storage locations or retrieval points. This automation eliminates the need for manual pallet handling, reducing labor costs and improving operational efficiency.

2. High-Density Storage: The Smart Pallet Shuttle system is designed to maximize storage capacity by utilizing high-density pallet racking structures. The shuttles can access multiple levels of the racking system, allowing for efficient vertical storage and making optimal use of available warehouse space.

3. Efficient Storage and Retrieval: The Smart Pallet Shuttle system optimizes storage and retrieval operations by selecting the most efficient path for shuttle movement. It can analyze inventory data, order patterns, and storage requirements to determine the optimal location for each pallet. This ensures fast and accurate storage and retrieval of pallets, minimizing travel time and improving overall productivity.

4. Real-time Inventory Tracking: The Smart Pallet Shuttle system is often integrated with a Warehouse Management System (WMS) or Inventory Management System (IMS). This integration enables real-time tracking and monitoring of inventory. It provides accurate visibility into pallet locations, stock levels, and inventory movements, facilitating better inventory management and order fulfillment processes.

5. Scalability and Flexibility: Smart Pallet Shuttle systems offer scalability and flexibility to accommodate changing storage needs. The system can be easily expanded or reconfigured to adapt to evolving warehouse requirements, allowing for seamless integration into existing warehouse operations.

6. Data Analytics and Optimization: Smart Pallet Shuttle systems can collect and analyze data related to pallet movements, storage patterns, and operational performance. This data can be leveraged for continuous process improvement, optimizing warehouse layout, and enhancing operational efficiency.

The Smart Pallet Shuttle system is utilized in various industries and sectors where efficient and automated storage and retrieval of palletized goods are critical. Here are some examples of industries that commonly employ the Smart Pallet Shuttle system:

1. Food and Beverage: The food and beverage industry often deals with large quantities of palletized goods, including perishable items. The Smart Pallet Shuttle system is extensively used in food processing plants, distribution centers, and cold storage facilities to optimize palletized storage, facilitate FIFO (First-In, First-Out) inventory rotation, and ensure proper temperature control.

2. Retail and E-commerce: Retailers and e-commerce companies with high-volume operations benefit from the Smart Pallet Shuttle system. It enables efficient storage and retrieval of palletized goods, streamlining order fulfillment processes, and ensuring quick access to products for retail stores or e-commerce order shipments.

3. Manufacturing and Automotive: Manufacturing plants, including automotive manufacturing facilities, utilize the Smart Pallet Shuttle system to store and retrieve palletized components, sub-assemblies, and finished products. This system ensures efficient supply chain management, just-in-time production, and optimized material flow within the manufacturing operations.

4. Chemical and Pharmaceutical: The chemical and pharmaceutical industries have specific storage requirements due to the nature of their products. The Smart Pallet Shuttle system is employed to handle palletized goods, such as chemical drums or pharmaceutical containers, ensuring safe and organized storage while enabling efficient inventory management and product traceability.

5. Logistics and Distribution: Logistics companies and distribution centers across various industries heavily rely on the Smart Pallet Shuttle system to optimize palletized goods handling. It enables efficient storage, retrieval, and cross-docking operations, reducing labor costs, and improving overall logistics operations.

6. Cold Storage and Freezer Facilities: Cold storage and freezer facilities, such as those used for storing frozen food or pharmaceuticals, often employ the Smart Pallet Shuttle system. It enables efficient storage and retrieval of pallets in temperature-controlled environments, ensuring proper inventory rotation and minimizing temperature fluctuations during pallet handling.

7. Third-Party Logistics (3PL): Third-party logistics providers utilize the Smart Pallet Shuttle system to efficiently manage and store palletized goods for multiple clients across different industries. This system enables secure storage, precise inventory management, and fast retrieval for order fulfillment.