Products

Ebil Tech

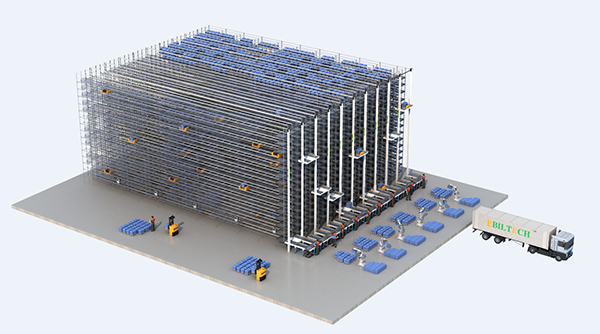

Dual-Level Shuttle System

Dual-Level Shuttle System is one of our products, we can provide one-stop storage system solutions and products, our products also include Warehouse Racing, Storage Rack, Bars and Tubes Storage Systems, Multi-Storey Shuttle Car, Medium-Duty Shelving Unit, Mechanical Mobile Shelving System, Smart Stacker, Steel Elevated Platform, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Atlanta (United States), Glorioso Islands, Sudan, Melilla, Columbus (United States), Sri Lanka, and so on. We are looking forward to cooperate with you. If you are interested in Dual-Level Shuttle System.

Here are the key features and characteristics of a Dual-Level Shuttle System:

1. High-Rise Racking: The Dual-Level Shuttle System is typically implemented in a high-rise racking configuration, consisting of multiple levels or tiers of storage positions. This design allows for vertical storage and retrieval operations, utilizing the available vertical space efficiently.

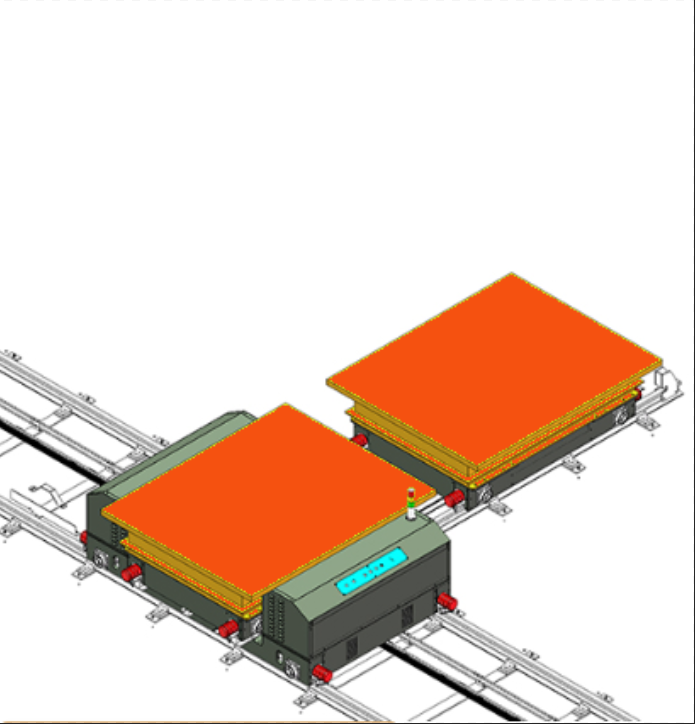

2. Shuttle Units: The system incorporates shuttle units, also known as shuttles or carriers, that move horizontally within the racking system. These shuttles are responsible for carrying goods or materials to and from the storage positions on each level.

3. Dual-Level Operation: The Dual-Level Shuttle System operates on two levels simultaneously. The shuttles can traverse both the upper and lower levels of the racking system, enabling efficient storage and retrieval operations across multiple levels.

4. Automated Operation: The Dual-Level Shuttle System operates autonomously, controlled by a central control system or warehouse management system (WMS). The control system provides instructions to the shuttles, directing them to the appropriate storage positions for storage or retrieval tasks.

5. Load Handling: The shuttles are equipped with mechanisms, such as forks or clamps, to handle and transport goods or materials. They can lift, move, and position pallets, containers, or other unitized loads within the storage positions on each level.

6. Scalability and Flexibility: The Dual-Level Shuttle System is scalable and adaptable to different warehouse sizes and layouts. It can be customized to accommodate various load sizes, weight capacities, and storage configurations, based on the specific requirements of the warehouse operations.

7. Enhanced Efficiency: The use of a Dual-Level Shuttle System offers benefits such as increased storage density, faster storage and retrieval operations, reduced labor requirements, and improved inventory management. By operating on multiple levels simultaneously, it optimizes material flow and maximizes the utilization of available space.

It's worth noting that specific implementations and configurations of the Dual-Level Shuttle System may vary depending on the manufacturer, the type of shuttle technology used, and the specific requirements of the warehouse or distribution center.