Products

Ebil Tech

Mini-Load Shuttle Car Solution

Mini-Load Shuttle Car Solution is one of our products, we can provide one-stop storage system solutions and products, our products also include Multi Shuttle Storage Rack, Pallet Runner Rack, Mother Child Shuttle, Archive Shelving, Electric Telescopic Cantilever Rack, Electric Mobile Shelving Systems, Mobile Shelving System, Shuttle Transporter, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Warsaw (Poland), Dominica, Niger, Cincinnati (United States), Maldives, Montenegro, and so on. We are looking forward to cooperate with you. If you are interested in Mini-Load Shuttle Car Solution.

The "Mini-Load Shuttle Car Solution" typically refers to an automated storage and retrieval system (AS/RS) used for handling small or mini-load items in a warehouse or distribution center. It is a material handling solution designed to efficiently store, retrieve, and transport smaller items such as bins, totes, or cartons within a facility.

The Mini-Load Shuttle Car Solution typically consists of the following components:

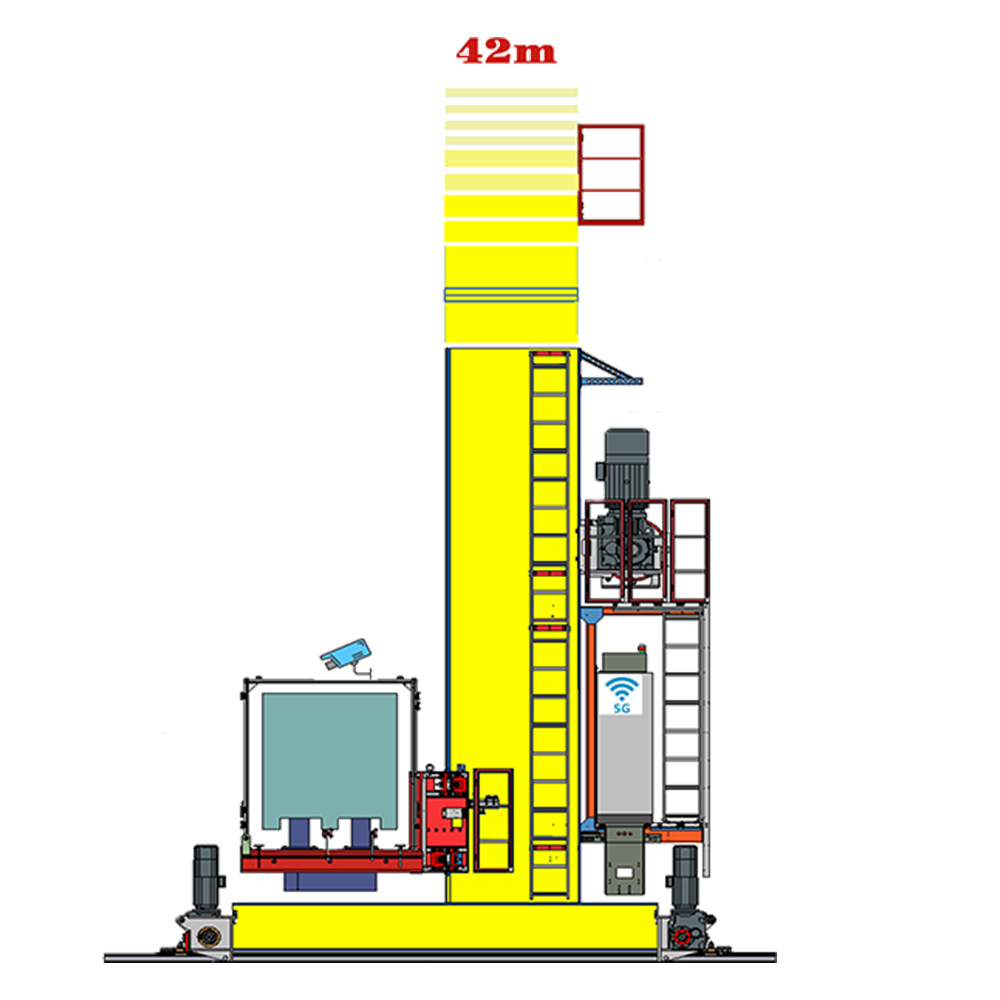

1. Shuttle Cars: These are automated vehicles that travel along designated tracks or aisles within the storage system. They are equipped with lifting mechanisms or platforms to pick up and transport the small load units.

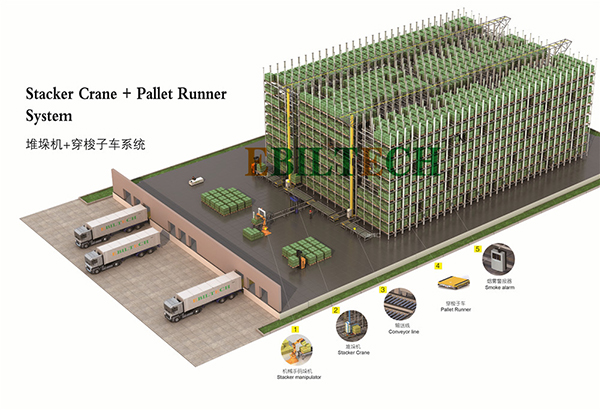

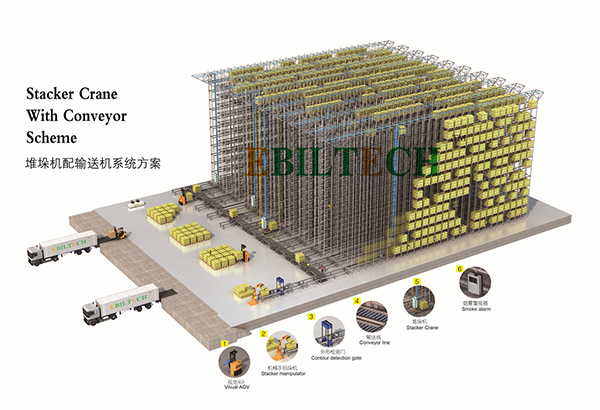

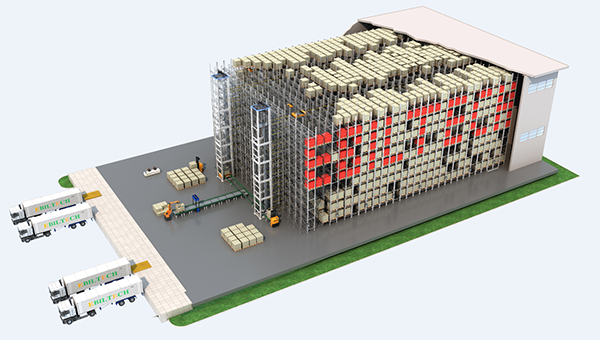

2. Racking System: The storage system consists of racks or shelving units with designated storage locations for the mini-load items. The shuttle cars move vertically and horizontally within the racking system to access the specified storage positions.

3. Control System: The Mini-Load Shuttle Car Solution is controlled by a central computerized system that manages the movement of the shuttle cars, tracks inventory, and coordinates the storage and retrieval operations. It receives commands from the warehouse management system (WMS) and ensures efficient and accurate operation of the system.

4. Automation and Integration: The Mini-Load Shuttle Car Solution is typically fully automated, minimizing the need for manual intervention. It integrates with other warehouse systems, such as conveyors, order picking systems, or robotic systems, to enable seamless material flow and optimize overall warehouse operations.

The key benefits of a Mini-Load Shuttle Car Solution include:

1. High Storage Density: The system allows for efficient use of vertical space by storing items in multiple levels or tiers within the racking system.

2. Fast and Accurate Retrieval: The automated shuttle cars enable quick and precise retrieval of the mini-load items, reducing picking times and improving order fulfillment rates.

3. Flexible and Scalable: The system can be easily adapted and expanded to accommodate changing storage needs and business growth.

4. Increased Efficiency: The automated nature of the Mini-Load Shuttle Car Solution reduces the reliance on manual labor, eliminates errors, and enhances overall operational efficiency.

The specific features and capabilities of a Mini-Load Shuttle Car Solution can vary depending on the manufacturer and the requirements of the facility. It is commonly used in industries such as e-commerce, retail, pharmaceuticals, and logistics, where there is a need for efficient storage and retrieval of small items.