Products

Ebil Tech

Bars and Tubes Storage Systems

Bars and Tubes Storage Systems is one of our products, we can provide one-stop storage system solutions and products, our products also include Automatic Stacker, Drive In Pallet Rack System, Multi-Level Steel Mezzanine Racking, Retractable Cantilever Rack, VNA Pallet Rack, Gravity Pallet Rack, Electric Mobile Racking, Multi Shuttle, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Campinas (Brazil), Manchester (UK), Aves Island, Canberra (Australia), Kinshasa (Congo), Kabardino-Balkar, and so on. We are looking forward to cooperate with you. If you are interested in Bars and Tubes Storage Systems.

Bars and tubes storage systems are specifically designed to efficiently store and organize long and narrow items such as bars, tubes, pipes, and other similar materials. These storage systems help maximize space utilization, provide easy access, and ensure the safe handling of these items.

There are several types of bars and tubes storage systems available, each with its own features and advantages. Here are some common types of bars and tubes storage systems:

1. Cantilever Racking: Cantilever racking is a popular choice for storing long and heavy items such as bars and tubes. It consists of vertical columns with horizontal arms that extend outward. The arms are adjustable in height and can be customized to accommodate different lengths of bars and tubes. Cantilever racking allows for easy loading and unloading using forklifts or other material handling equipment.

2. Vertical Bar Racks: Vertical bar racks are designed to store bars and tubes vertically. These racks have multiple compartments or slots that can hold individual pieces of varying lengths. Vertical bar racks are often wall-mounted or freestanding and provide efficient storage while keeping the items organized and easily accessible.

3. Horizontal Bar Racks: Horizontal bar racks, also known as bar cradles, are designed to store bars and tubes horizontally. They feature a base or frame with dividers or slots to hold the bars in a horizontal position. Horizontal bar racks can be stacked or placed side by side to create a space-saving storage solution.

4. Pipe and Tube Storage Systems: Pipe and tube storage systems are specialized storage solutions designed specifically for pipes and tubes. These systems often use racks or shelves with dividers or compartments to separate and organize individual pipes or tubes. They can be customized to accommodate different sizes and lengths of pipes, providing a neat and organized storage solution.

5. A-Frame Racks: A-frame racks are triangular-shaped racks with multiple levels designed to store long and narrow items at an inclined angle. The items lean against the angled arms, providing stability and easy access. A-frame racks are commonly used for storing items such as metal bars, rods, or lumber.

6. Roll-out Racks: Roll-out racks feature sliding shelves or drawers that allow easy access to long items such as bars and tubes. These racks can be rolled out to provide complete visibility and convenient loading or unloading. Roll-out racks are particularly useful when frequent access to different items is required.

7. Mobile Racks: Mobile racks are storage systems mounted on wheels or rails, allowing them to move horizontally. These racks are often used to store long items in a compact manner, and they can be easily moved to create access aisles when needed. Mobile racks are beneficial in maximizing space utilization and providing flexible storage options.

8. Gravity Flow Racks: Gravity flow racks, also known as gravity flow lanes or flow-through racks, utilize inclined roller or conveyor systems to allow bars and tubes to flow smoothly from the loading end to the unloading end. These racks are ideal for high-density storage and first-in, first-out (FIFO) inventory management. They ensure easy access and rotation of long items while maximizing space utilization.

9. Rotary Bar Storage Systems: Rotary bar storage systems are designed to store and retrieve bars and tubes in a compact and organized manner. These systems consist of rotating carousels or towers with multiple compartments that hold the items. By rotating the carousel, the desired bar or tube can be brought to the access point, providing efficient storage and retrieval.

10. Rack Supported Mezzanines: Rack supported mezzanines are multi-level platforms constructed using pallet racking as the supporting structure. These mezzanines provide additional floor space above the racking system, which can be utilized for storing bars and tubes. They maximize vertical space utilization while allowing easy access to stored items.

11. Bar Cradles: Bar cradles are designed to hold bars and tubes horizontally and are often used for storing longer or heavier items. They consist of a cradle-like structure that supports and secures the bars or tubes in a horizontal position. Bar cradles can be standalone units or integrated into larger storage systems.

12. Pallet Racking: While primarily used for palletized goods, pallet racking systems can also be adapted to store bars and tubes. By using specialized supports or dividers, pallet racking can create dedicated storage locations for long items. This allows for efficient use of vertical space and easy access to individual bars or tubes.

13. Drum Racks: Drum racks, typically used for storing drums or barrels, can also be utilized for storing long items like bars and tubes. These racks feature horizontal supports or cradles designed to secure the items in a horizontal position. Drum racks can be adjustable or fixed, depending on the specific storage requirements.

14. Lumber Racks: Lumber racks are specifically designed for storing lumber and other long items, including bars and tubes. These racks typically feature multiple levels with angled supports or dividers to keep the items organized and accessible. Lumber racks are commonly used in woodworking shops, construction sites, and warehouses.

15. Wire Mesh Containers: Wire mesh containers can be utilized to store bars and tubes securely. These containers have an open wire mesh design that allows for visibility and ventilation while ensuring the items are contained. They are stackable, durable, and suitable for various storage environments.

16. Customized Storage Solutions: Depending on the specific needs of your facility, customized storage solutions can be designed and built to accommodate bars and tubes. These solutions may involve a combination of different rack types, adjustable supports, and specialized fixtures to optimize storage capacity and accessibility.

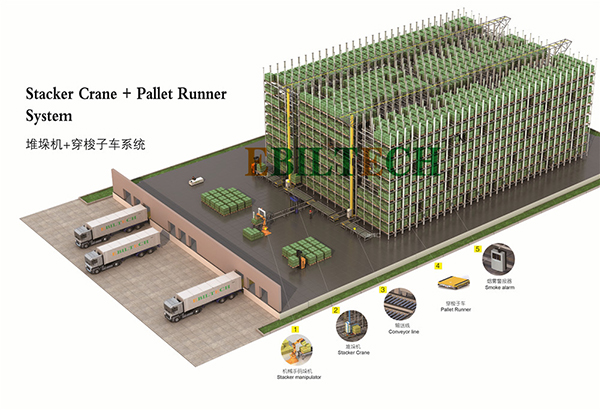

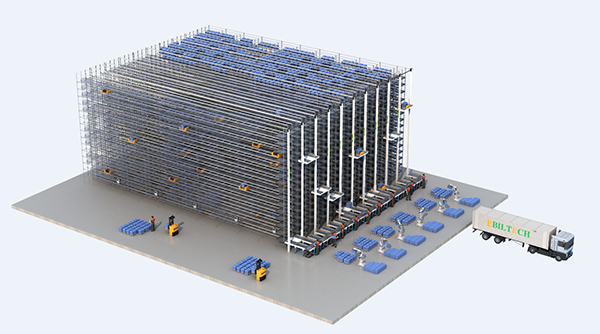

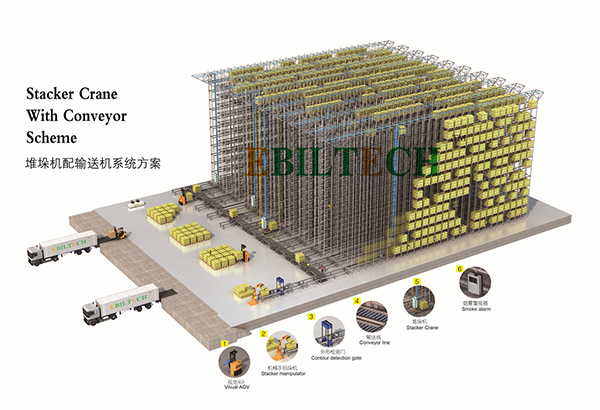

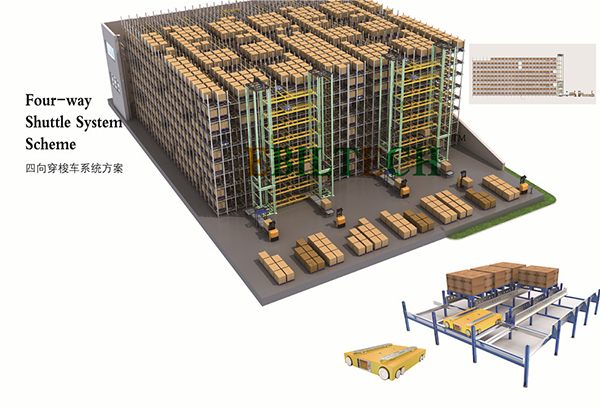

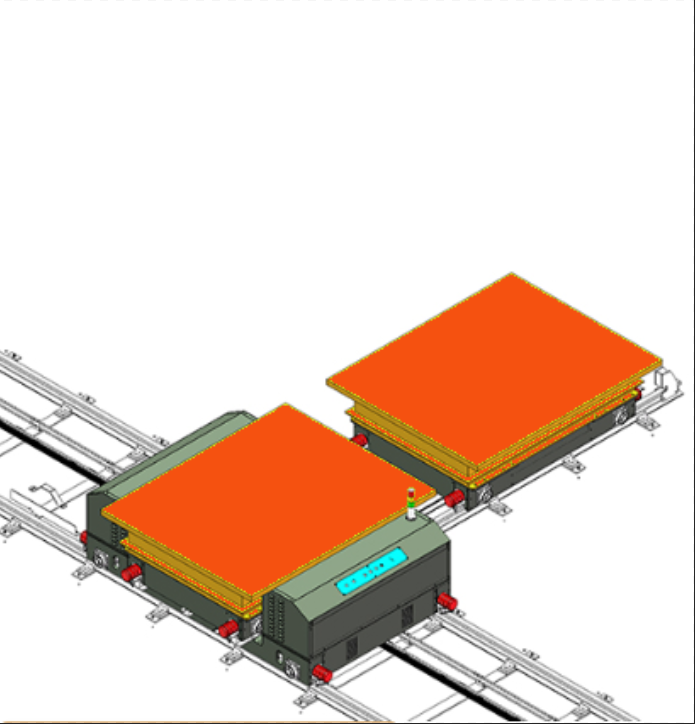

17. Automated Storage and Retrieval Systems (AS/RS): AS/RS systems are advanced automated solutions that utilize robotics, conveyors, and computer-controlled mechanisms to store and retrieve items. These systems can be customized to handle bars and tubes by using specialized grippers or clamps. AS/RS systems offer high-density storage, efficient handling, and precise inventory control.

18. Vertical Lift Modules (VLMs): VLMs are vertical storage systems that consist of a series of vertically arranged trays or shelves. The trays are accessed by an automated lift mechanism that retrieves and delivers the requested items. VLMs provide high-density storage, space optimization, and automated handling of bars and tubes.

19. Warehouse Management Systems (WMS): While not a physical storage system, a Warehouse Management System is software that streamlines and optimizes warehouse operations, including inventory management, order fulfillment, and storage location control. Implementing a WMS can enhance the efficiency and accuracy of storing and retrieving bars and tubes in any storage system.

When selecting a bars and tubes storage system, consider factors such as the length, weight, and quantity of the items, available space, accessibility requirements, and the specific needs of your application. Consulting with storage system providers or experts can help you choose the most suitable system for your specific requirements.

Applications of bars and tubes storage systems

Bars and tubes storage systems find applications in various industries where the efficient storage and organization of long and narrow items are essential. Some common applications of bars and tubes storage systems include:

1. Manufacturing and Fabrication: Bars and tubes are widely used in manufacturing and fabrication processes, such as metalworking and construction. Storage systems allow for the orderly arrangement of these items, ensuring easy access and retrieval during production. This helps streamline operations, reduce downtime, and optimize workflow efficiency.

2. Warehousing and Distribution: In warehouses and distribution centers, bars and tubes storage systems enable efficient storage and inventory management. By utilizing specialized storage solutions, such as cantilever racking or vertical bar racks, these facilities can maximize space utilization, keep inventory organized, and facilitate quick and accurate order fulfillment.

3. Retail and Wholesale: Retailers and wholesalers dealing with long items like pipes, tubes, and bars require storage systems to manage their inventory effectively. By implementing appropriate storage solutions, they can ensure the availability of products, enhance visual merchandising, and facilitate efficient stock rotation.

4. Metal Service Centers: Metal service centers that supply bars, tubes, and other metal products rely on storage systems to handle their extensive inventory. These systems enable them to categorize and store various types, sizes, and lengths of metal items, ensuring easy identification, retrieval, and delivery to customers.

5. Construction Sites: On construction sites, bars and tubes storage systems play a crucial role in organizing and storing construction materials. These systems help keep the site clean, prevent damage or distortion of the materials, and enhance safety by minimizing clutter and potential hazards.

6. Automotive and Aerospace Industries: The automotive and aerospace industries often require storage systems for long and narrow items like tubes for exhaust systems or bars for structural components. Proper storage solutions allow for the systematic arrangement of these items, ensuring easy access for assembly lines or maintenance operations.

7. Plumbing and HVAC: Plumbing and HVAC (Heating, Ventilation, and Air Conditioning) contractors frequently deal with pipes and tubes of various lengths and dimensions. Proper storage systems enable them to store and organize these items, ensuring quick access during installations or repairs.

8. Recycling and Scrap Yards: Recycling facilities and scrap yards often handle bars and tubes as part of their operations. Storage systems help them segregate and store these items efficiently, enabling easy sorting, processing, and transportation for recycling or reuse.

9. Oil and Gas Industry: The oil and gas industry utilizes bars and tubes storage systems to store pipes, casings, and other tubular products. These systems help maintain the integrity of the materials, prevent damage, and facilitate efficient inventory management at drilling sites, refineries, and distribution centers.

10. Renewable Energy: The renewable energy sector, including wind and solar power, relies on bars and tubes storage systems to store components such as wind turbine blades, solar panel frames, and mounting structures. These storage systems ensure safe and organized handling of these large and delicate items during installation, maintenance, and transportation.

11. Shipbuilding and Marine Industry: Shipbuilding and marine industries involve the fabrication and installation of various structures, including bars and tubes for shipbuilding, offshore platforms, and marine infrastructure. Storage systems play a crucial role in organizing and storing these items in shipyards and fabrication facilities, ensuring easy access and efficient workflow.

12. Sports and Fitness Equipment: Manufacturers, distributors, and retailers of sports and fitness equipment often require storage systems for items like barbells, weightlifting bars, and exercise tubes. Proper storage solutions facilitate inventory management, prevent damage, and provide easy access for customers in sports facilities, gyms, or retail outlets.

13. Art and Display: Bars and tubes storage systems are also used in art galleries, museums, and exhibition spaces to store and display artwork, sculptures, or large installations. These systems allow for safe and organized storage of delicate and valuable pieces, while also providing flexibility for changing exhibits and installations.

14. Event and Stage Production: Bars and tubes storage systems play a crucial role in event and stage production. They are used to store lighting trusses, stage rigging equipment, and other production elements. These storage systems ensure quick access, efficient setup, and safe handling of equipment during events, concerts, and theatrical productions.

15. Research and Development: Research facilities, laboratories, and educational institutions often require storage systems for storing bars and tubes used in scientific experiments, prototypes, or research projects. These systems enable orderly storage, easy access, and efficient organization of materials, contributing to a productive research environment.

These are just a few examples of the applications of bars and tubes storage systems. The versatility of these storage solutions makes them valuable across numerous industries where the efficient management of long and narrow items is critical.

Components of bars and tubes storage systems

Bars and tubes storage systems typically consist of several key components that work together to provide efficient and organized storage. The specific components may vary depending on the type of storage system, but here are some common elements:

1. Racking or Shelving: Racking or shelving forms the foundation of a bars and tubes storage system. It provides the structural support and storage space for the items. Different types of racking or shelving may be used, such as cantilever racks, pallet racks, or specialized tube racks, depending on the specific storage requirements.

2. Supports or Dividers: Supports or dividers are used to separate and organize individual bars and tubes within the storage system. They can be adjustable or fixed, and they help prevent items from rolling or shifting, ensuring stability and preventing damage. Examples include horizontal cradles, dividers, or foam inserts.

3. Uprights and Beams: Uprights and beams are key components of pallet racking systems. Uprights are vertical columns that provide vertical support, while beams are horizontal components that connect the uprights and create the levels or tiers of storage. They are designed to withstand the weight and load of the stored bars and tubes.

4. Clamps or Grippers: In some specialized storage systems, clamps or grippers are used to securely hold bars and tubes in place. These components can be adjustable to accommodate different sizes and diameters. Clamps or grippers ensure that the items remain stable and prevent them from falling or shifting during storage or retrieval.

5. Rollers or Conveyors: Storage systems like gravity flow racks may incorporate rollers or conveyors to facilitate the smooth movement of bars and tubes within the system. These components allow for easy loading and unloading of items, ensuring efficient flow and accessibility.

6. Safety Features: Safety features are vital components of bars and tubes storage systems to ensure the protection of personnel and prevent accidents. These can include safety barriers, protective guards, or signage to indicate load capacities, restricted areas, or potential hazards.

7. Accessories and Add-ons: Additional accessories and add-ons can enhance the functionality and versatility of bars and tubes storage systems. These may include labeling systems, hooks, brackets, or attachments for hanging tools or accessories related to the stored items. Accessories provide customization options and help optimize storage efficiency.

8. Control Systems (for automated systems): In automated storage systems, control systems play a crucial role. These systems include software, sensors, and control panels that manage and coordinate the automated storage and retrieval processes. They ensure accurate inventory control, tracking, and efficient handling of bars and tubes.

9. Identification and Labeling Systems: Identification and labeling systems are used to mark and identify individual bars and tubes within the storage system. This can include barcode labels, RFID tags, or color-coded markers. These systems facilitate easy identification and tracking of specific items, streamlining inventory management and retrieval processes.

10. Anchoring and Fastening Components: Anchoring and fastening components are used to secure the storage system to the floor or wall, ensuring stability and safety. These components can include anchor bolts, brackets, or seismic restraints, depending on the specific requirements and regulations of the facility.

11. Ladders, Platforms, or Stairs: In larger storage systems or multi-level configurations, ladders, platforms, or stairs may be incorporated to provide access to higher levels. These components allow personnel to safely reach and navigate the storage system for loading, unloading, or maintenance purposes.

12. Safety Equipment: Safety equipment is an essential component of any storage system to ensure a safe working environment. This can include safety barriers, guardrails, anti-slip flooring, or safety signage. These components help prevent accidents, protect personnel, and maintain compliance with safety regulations.

13. Lighting: Adequate lighting is crucial in bars and tubes storage systems to enhance visibility and ensure safe operations. Lighting fixtures, such as overhead lights or task lighting, may be installed to illuminate the storage areas and improve visibility for personnel during loading, unloading, and inventory management tasks.

14. Fire Suppression Systems: Depending on the nature of the stored items and the regulations in place, fire suppression systems may be integrated into the storage system. This can include fire sprinklers, fire extinguishers, or fire suppression systems designed to detect and control fires in the event of an emergency.

15. Monitoring and Security Systems: Monitoring and security systems can be implemented to safeguard the stored bars and tubes. This can include CCTV cameras, access control systems, or intrusion detection systems. These components help monitor the storage area, prevent theft or unauthorized access, and ensure the security of valuable inventory.

These are some of the key components that are commonly found in bars and tubes storage systems. The specific components used will depend on the storage system design, the type of items being stored, and the operational requirements of the facility.

Price of different bars and tubes storage systems

The price of different bars and tubes storage systems can vary widely depending on several factors, including the type of storage system, its size and capacity, material quality, customization options, and additional features. It's important to note that prices can fluctuate based on market conditions and individual suppliers. Here are some general price ranges for different types of storage systems:

1. Cantilever Racks: Cantilever racks are commonly used for storing long and bulky items like bars and tubes. The prices for cantilever racks can range from a few hundred dollars for smaller, basic configurations to several thousand dollars for larger systems with higher load capacities and additional features.

2. Pallet Racking Systems: Pallet racking systems, which can be adapted to store bars and tubes, offer versatility and high storage density. The cost of pallet racking systems can vary significantly depending on factors such as the size, configuration, load capacity, and whether they are new or used. Prices can range from a few hundred dollars to several thousand dollars per upright frame and beam set.

3. Tube Racks: Tube racks are specifically designed for storing tubes and cylindrical items. The price of tube racks depends on factors such as the size, number of levels, and load capacity. Basic tube racks can start at a few hundred dollars, while larger or customized systems may cost several thousand dollars.

4. Automated Storage and Retrieval Systems (AS/RS): AS/RS systems, which can be used for bars and tubes storage, involve advanced automation and technology. The cost of AS/RS systems can be substantial due to the complexity and customization involved. These systems can range from tens of thousands to millions of dollars, depending on the scale, complexity, and specific requirements of the system.

5. Specialty Storage Systems: There are various specialty storage systems available for specific applications, such as roll-out racks, vertical bar racks, or mobile storage systems. The prices for these specialty systems can vary depending on their design, features, and load capacities. Prices can range from a few hundred dollars for smaller, basic configurations to several thousand dollars for larger or customized systems.

6. Vertical Bar Racks: Vertical bar racks are designed to store bars and tubes vertically, maximizing vertical space utilization. Prices for vertical bar racks can range from a few hundred dollars for smaller racks to around a thousand dollars or more for larger and heavy-duty models.

7. Roll-out Racks: Roll-out racks provide easy access to stored bars and tubes by allowing them to roll out for convenient loading and unloading. The cost of roll-out racks can vary depending on their size, capacity, and customization options. Prices typically start at a few hundred dollars and can go up to a few thousand dollars.

8. Mobile Storage Systems: Mobile storage systems, such as mobile shelving or racking systems, use movable bases to maximize space utilization. These systems can be beneficial for bars and tubes storage. The prices for mobile storage systems depend on factors such as system size, configuration, and additional features. Prices can range from a few thousand dollars to tens of thousands of dollars or more.

9. Mezzanine Storage Systems: Mezzanine storage systems involve the installation of an elevated platform or floor to create additional storage space. The cost of mezzanine storage systems can vary significantly depending on the size, load capacity, and customization options. Prices typically start at several thousand dollars and can go up to tens of thousands of dollars or more, depending on the complexity and size of the system.

10. Customized Storage Systems: Customized storage systems are designed to meet specific requirements and can be tailored to accommodate bars and tubes. The price of customized storage systems can vary greatly depending on the level of customization, materials used, size, and additional features. Prices for customized systems can range from several thousand dollars to tens of thousands of dollars or more, depending on the complexity and specifications.

It's important to note that the prices mentioned above are approximate and can vary significantly based on region, supplier, customization requirements, and other factors. It is recommended to consult with storage system providers or suppliers to get accurate pricing information based on specific needs and requirements.