Products

Ebil Tech

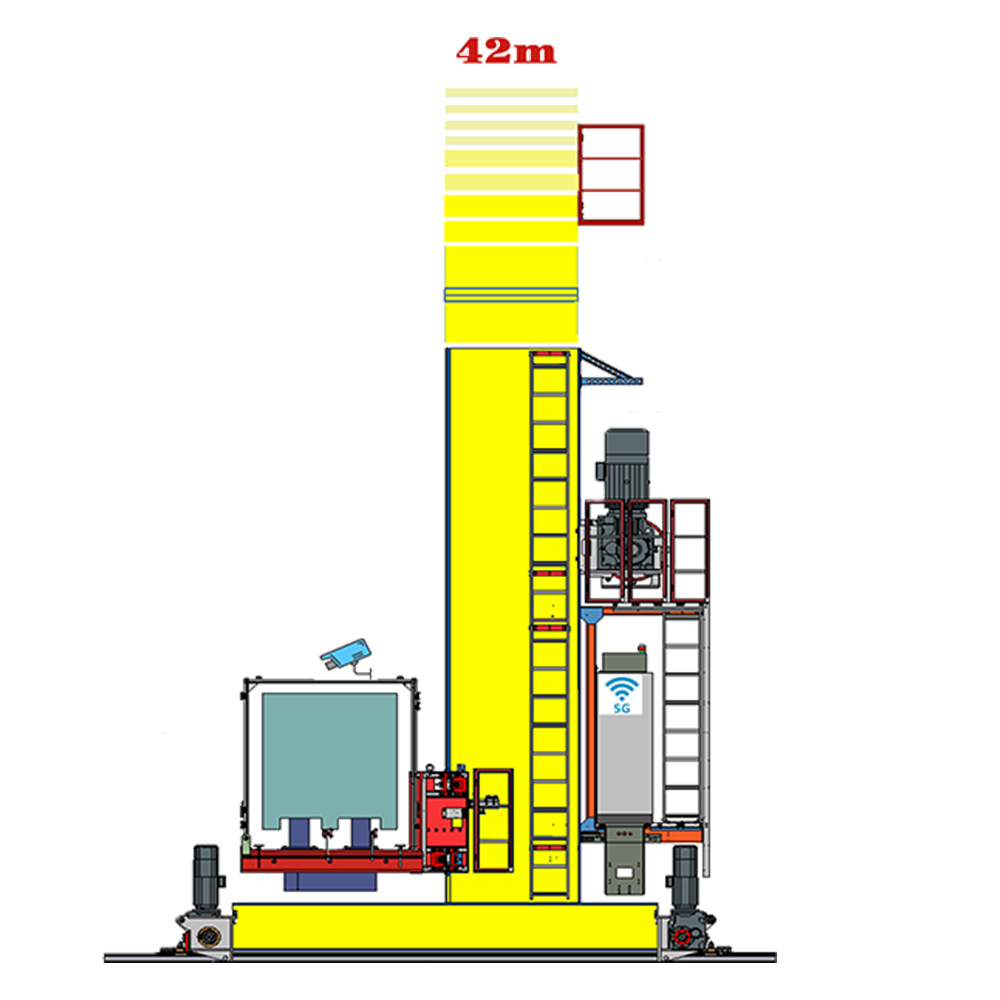

Material Lift

Material Lift is one of our products, we can provide one-stop storage system solutions and products, our products also include Extendable cantilever rack, Warehouse Drive In Rack, Electric Movable Racking, Multi-Level Shuttle Rack, Tear Drop Pallet Rack, Retrieval Crane Rack, Four-Directional Shuttle Racking System, Selective Pallet Racking, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Antigua and Barbuda, Myanmar, Minsk (Belarus), Cyprus, Lausanne (Switzerland), Udmurt, and so on. We are looking forward to cooperate with you. If you are interested in Material Lift.

A material lift, also known as a vertical reciprocating conveyor (VRC) or a freight lift, is a type of lifting device used to transport materials or goods vertically between different levels within a facility. It is designed to facilitate the movement of heavy loads, such as pallets, cartons, or equipment, in a safe and efficient manner.

Material lifts find applications in various industries and settings, including warehouses, distribution centers, manufacturing facilities, retail stores, and hospitals. They provide a cost-effective and efficient solution for vertical material handling, reducing the reliance on manual labor and minimizing the risk of injuries associated with manual lifting or using conventional elevators for heavy loads.

It's important to consult with industry experts or suppliers to determine the specific requirements, regulations, and safety considerations for material lifts in your particular application or region.

Here are some key features and characteristics of a material lift:

1. Vertical Transport: Material lifts are specifically designed for vertical transportation of goods. They can move items between different levels, such as mezzanines, floors, or storage areas within a building or facility.

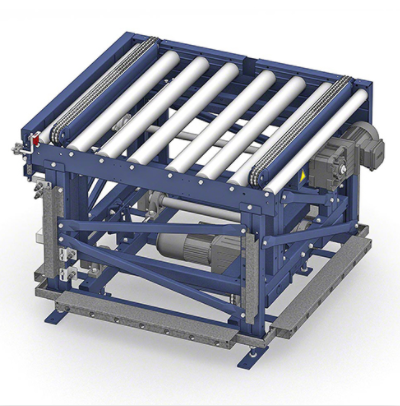

2. Loading and Unloading: Material lifts typically consist of a platform or carriage that can be loaded with goods or materials. This platform is raised or lowered using a lifting mechanism, such as hydraulic, mechanical, or electric systems. The platform may have gates or doors to secure the load during transport.

3. Weight Capacity: Material lifts are designed to handle heavy loads, with weight capacities ranging from a few hundred pounds to several tons, depending on the specific model and application requirements.

4. Safety Features: Material lifts are equipped with various safety features to ensure the protection of personnel and goods during operation. These features may include safety gates or barriers, interlocking doors, emergency stop buttons, overload protection systems, and safety sensors to detect obstructions.

5. Control Systems: Material lifts can be operated using control systems, which may include push-button controls, pendant controls, or remote controls. These systems allow for easy and precise operation of the lift, including raising, lowering, and stopping at desired levels.

6. Compliance with Standards: Material lifts are subject to safety standards and regulations to ensure the safe handling of loads and the well-being of personnel. Compliance with standards, such as ASME B20.1 or local regulations, is essential for the design, installation, and operation of material lifts.