Products

Ebil Tech

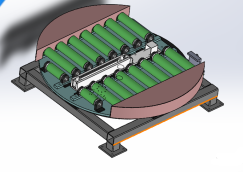

Drive In Rack System

Drive In Rack System is one of our products, we can provide one-stop storage system solutions and products, our products also include VNA Forklift Trucks, Multi-Directional Shuttle Car, Cold Chain Storage Rack, High-Density Racking System, Multi-Level Stacker, Selective Rack, Drawer Rack for lengthy goods, Drive Through Rack System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Nagoya (Japan), Nantes (France), Paris (France), Eritrea, Micronesia, Botswana, and so on. We are looking forward to cooperate with you. If you are interested in Drive In Rack System.

A drive-in rack system is a type of high-density storage solution designed for warehouses that need to store large quantities of the same SKU (stock-keeping unit). It maximizes storage capacity by eliminating aisles between racks, allowing forklifts to drive directly into the rack structure for loading and unloading pallets. Here's some information about drive-in rack systems:

1. Design:

- Structure: Drive-in rack systems typically consist of upright frames and horizontal load rails or beams that support the pallets. The frames are connected with bracing to provide stability and strength to the system.

- Entry and Exit: Drive-in racks usually have a single entry and exit point, allowing forklifts to access the racks from one side. This design optimizes storage space by eliminating the need for multiple aisles.

- Last-In, First-Out (LIFO): Drive-in rack systems operate on a last-in, first-out (LIFO) principle. This means that the most recently loaded pallet is the first to be retrieved.

2. Advantages:

- High-Density Storage: Drive-in racks maximize storage density by eliminating aisles and utilizing vertical space. They are ideal for storing large quantities of the same SKU.

- Cost-Effective: Drive-in rack systems can be a cost-effective storage solution as they maximize storage capacity and reduce the need for additional rack structures.

- Suitable for Cold Storage: Drive-in racks are commonly used in cold storage facilities where space optimization is crucial due to the higher cost of refrigerated or frozen space.

3. Considerations:

- Limited Selectivity: Drive-in rack systems offer limited selectivity since pallets are stored in a stacked manner. Retrieving a specific pallet may require moving other pallets in front of it.

- Impact on Accessibility: Due to the stacked configuration, accessibility to individual pallets may be slower compared to other rack systems. It is important to consider the trade-off between storage density and accessibility needs.

It's important to note that the design and specifications of drive-in rack systems can vary based on the specific requirements of each warehouse and the type of loads being stored. The pricing for drive-in rack systems can also vary widely depending on factors such as rack height, load capacity, customization requirements, location, supplier, and other project-specific needs. To obtain an accurate price quote, it is recommended to consult with multiple suppliers or racking manufacturers who can provide detailed pricing based on your specific warehouse layout and requirements.