Products

Ebil Tech

Vertical Lift

Vertical Lift is one of our products, we can provide one-stop storage system solutions and products, our products also include High-Density Storage Rack, Storage Rack, Shuttle Cart, Four-Way Shuttle Racking System, Electric Movable Racking System, Drive Through Rack System, Warehouse Flow Rack, Metal Pallet Racks, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Gambia, Svalbard, Bucharest (Romania), Congo (Brazzaville), The Hague (Netherlands), Bremen (Germany), and so on. We are looking forward to cooperate with you. If you are interested in Vertical Lift.

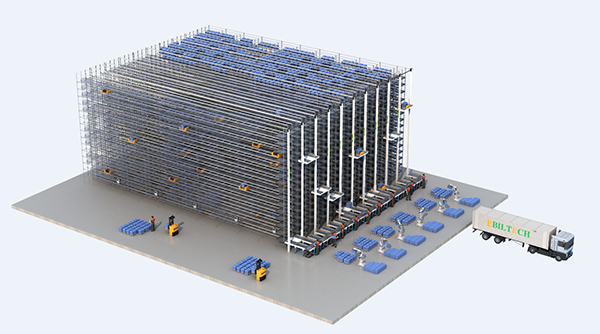

Vertical Lift, also known as a Vertical Lift Module (VLM), is an automated storage and retrieval system used for efficient vertical storage of goods in warehouses, distribution centers, and other industrial settings. It is designed to maximize storage density, improve picking accuracy, and optimize inventory management.

Vertical Lift systems offer several benefits, including increased storage density, improved picking accuracy and speed, reduced labor requirements, and enhanced inventory control. By utilizing the vertical space effectively, they can optimize the use of floor space in warehouses and provide quick access to stored items.

The specific design and capabilities of Vertical Lift systems may vary among manufacturers and based on the intended application and requirements of the facility.

Here are the key features and components of a Vertical Lift system:

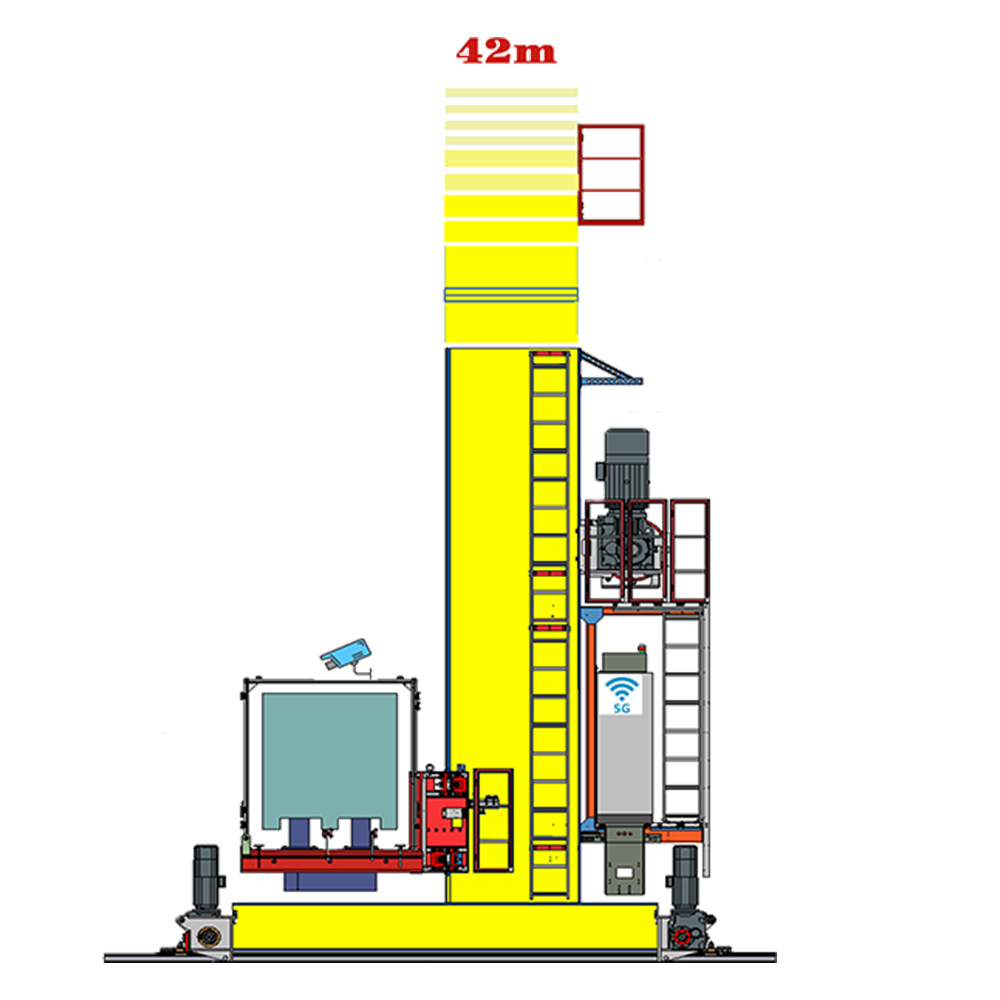

1. Vertical Carriages: The primary components of a Vertical Lift system are the vertical carriages or columns. These carriages consist of multiple trays or shelves that are stacked vertically. The carriages move up and down within the system to access the desired tray or shelf for storage or retrieval.

2. Storage Trays: Each tray within the vertical carriages is designed to hold goods or products. The trays are typically adjustable to accommodate different sizes and shapes of items. They can be equipped with dividers, bins, or other organizing features to facilitate efficient storage and retrieval.

3. Lift Mechanism: The lift mechanism is responsible for raising and lowering the vertical carriages within the system. It can be powered by electric motors or hydraulic systems, depending on the design and manufacturer. The lift mechanism moves the carriages to position the desired tray at the access opening for picking or storage operations.

4. Control System: A control system is integrated into the Vertical Lift system to manage its operations. It includes user interface panels or software that allow operators to input commands, select the desired tray, and monitor the system's performance. The control system can also be integrated with warehouse management systems (WMS) or other software for seamless inventory control.

5. Safety Features: Vertical Lift systems incorporate various safety features to ensure the protection of personnel and goods. These features may include emergency stop buttons, safety sensors to detect obstructions or personnel in the access area, and safety interlocks to prevent unauthorized access during operation.

6. Integration and Automation: Vertical Lift systems can be integrated with other automated systems and technologies, such as conveyor systems, robotic picking systems, or barcode scanners. This integration allows for a more streamlined and efficient material handling process, reducing manual labor and enhancing overall productivity.