Products

Ebil Tech

Smart Stacker

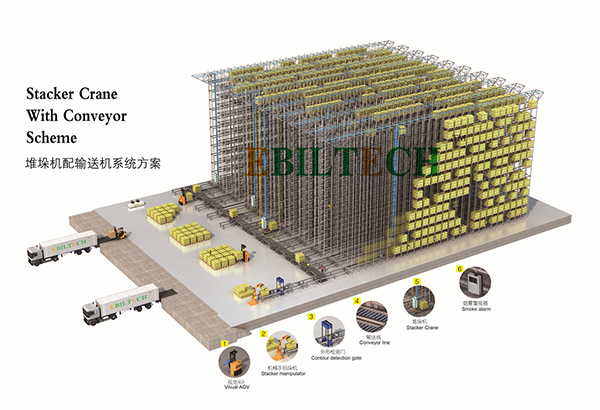

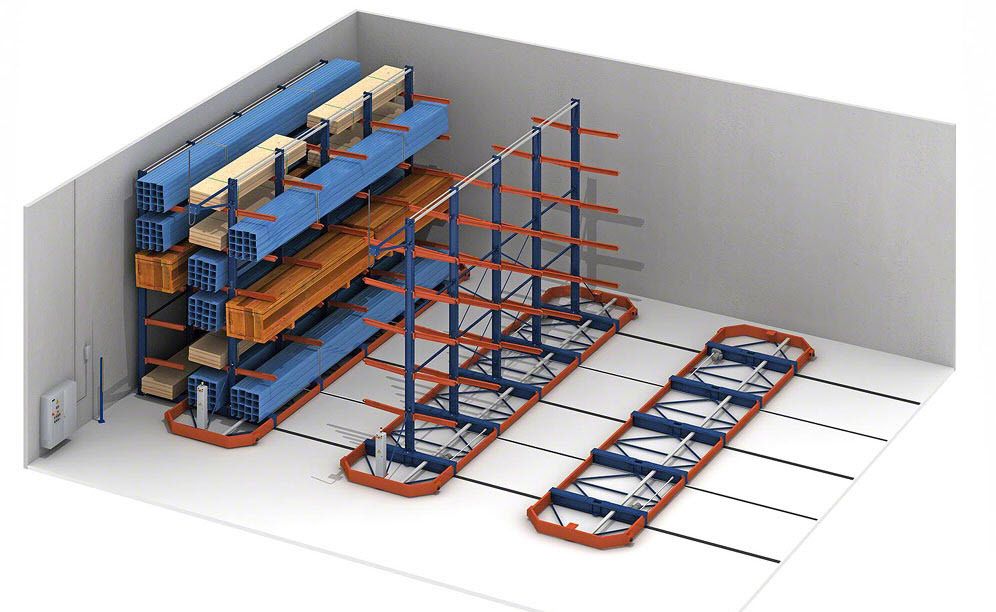

Smart Stacker is one of our products, we can provide one-stop storage system solutions and products, our products also include Warehouse Equipment, Goods Lift, Automatic Stacker Crane, Motor-driven cantilever racking system, Low-Temperature Storage Rack, Roll Out Steel Storage Racks, VNA Pallet Racking System, Electric Movable Racking System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Dammam (Saudi Arabia), Douala (Cameroon), Port Elizabeth/Mandela City (South Africa), Virgin Islands, British, Malta, Fukuoka (Japan), and so on. We are looking forward to cooperate with you. If you are interested in Smart Stacker.

Smart Stacker as an Automated Guided Vehicle (AGV):

In the context of material handling and logistics, a Smart Stacker can refer to an automated guided vehicle designed for stacking and transporting goods within a warehouse or distribution center. These AGVs are equipped with sensors, cameras, and navigation systems that allow them to autonomously navigate through the facility, locate pallets or containers, and stack or unstack them as required. Smart Stackers are programmed to follow predefined routes, interact with other equipment, and optimize the movement and storage of goods.

Smart Stacker as a Software Solution:

Smart Stacker can also refer to a software solution or algorithm used in the field of container or pallet loading optimization. It is designed to determine the most efficient way to stack and arrange items within containers or on pallets, taking into consideration various factors such as weight distribution, stability, and space utilization. This software solution uses advanced algorithms to analyze the dimensions and characteristics of the items to be stacked and generates an optimized stacking plan, ensuring that space is maximized and the load is stable during transportation or storage.

Smart Stackers, or automated guided vehicles (AGVs) designed for stacking and transporting goods, are commonly used in various industries and sectors where material handling and logistics operations are involved. Some specific industries and sectors where Smart Stackers are commonly employed include:

1. Warehousing and Distribution: Smart Stackers are widely used in warehouses and distribution centers to automate the movement and stacking of goods. They help optimize storage space, improve picking efficiency, and streamline order fulfillment processes.

2. Manufacturing: Smart Stackers are utilized in manufacturing facilities for tasks such as stacking and transporting raw materials, components, and finished products. They contribute to efficient material flow, reduce manual labor, and enhance production line operations.

3. E-commerce and Retail: With the growth of e-commerce and the need for efficient order fulfillment, Smart Stackers are extensively utilized in e-commerce warehouses and retail distribution centers. They assist in picking, sorting, and stacking items for order preparation and shipment.

4. Logistics and Freight Handling: Smart Stackers play a crucial role in logistics and freight handling operations, including container terminals, ports, and transportation hubs. They are used for loading and unloading containers, stacking pallets, and optimizing the utilization of storage spaces.

5. Food and Beverage: In the food and beverage industry, Smart Stackers are employed for tasks such as stacking and transporting pallets of goods, including perishable items. They ensure proper handling of products and help maintain inventory accuracy.

6. Automotive and Manufacturing Plants: Smart Stackers find application in automotive manufacturing plants and other heavy industries. They assist in handling large and heavy loads, such as automotive components, metal sheets, and machinery parts.

Smart Stackers can optimize storage space in warehouses through various methods and features. Here are some ways in which Smart Stackers contribute to space optimization:

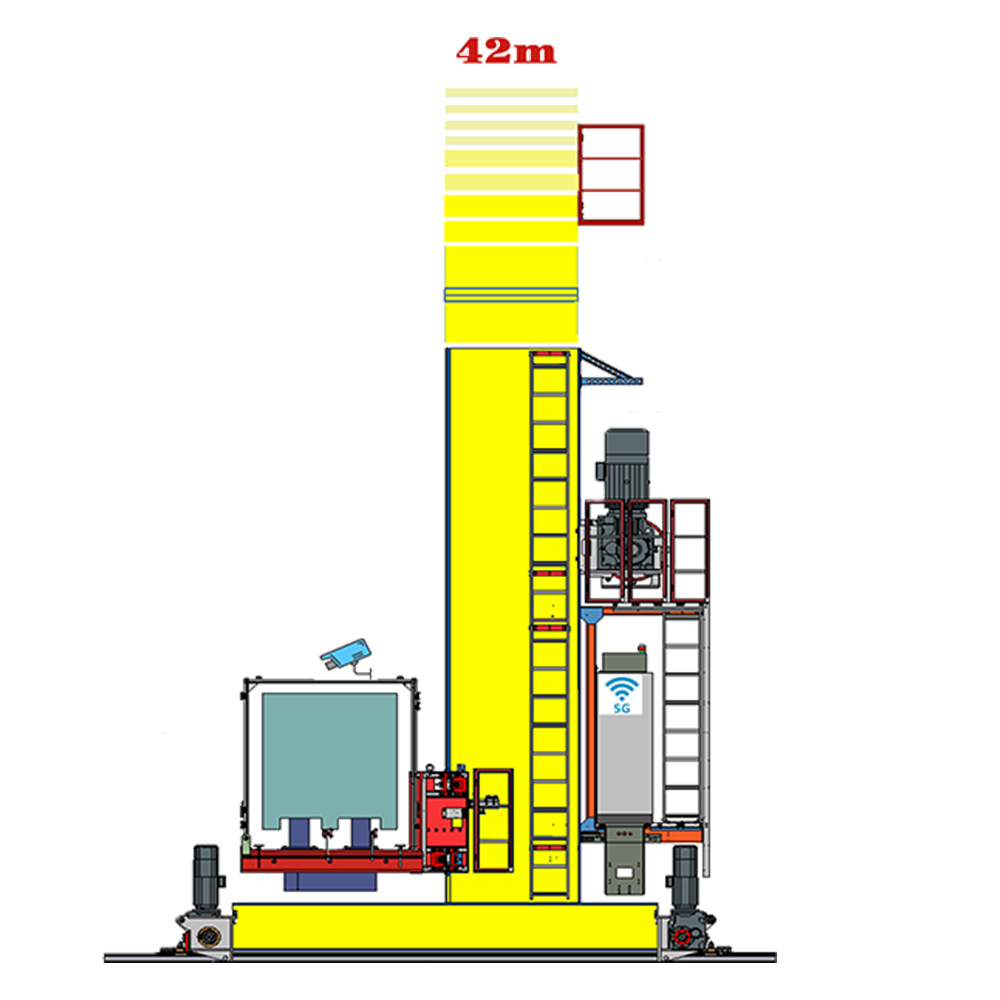

1. Vertical Storage: Smart Stackers are capable of reaching high shelves or racks, enabling vertical storage utilization. By stacking goods vertically, they make efficient use of the available vertical space in the warehouse, maximizing storage capacity.

2. Compact Stacking: Smart Stackers are designed to stack goods in a compact and efficient manner. They can analyze the dimensions and shapes of items, optimize stacking patterns, and minimize wasted space between items. This ensures that goods are stacked tightly together, reducing empty spaces and maximizing storage density.

3. Dynamic Slotting: Smart Stackers can dynamically slot items in real-time based on demand and order frequency. By analyzing order history and demand patterns, they can adjust the placement of items to improve accessibility and reduce travel time. Frequently picked items are typically placed in easily accessible locations, optimizing the flow of goods and reducing unnecessary movements.

4. Intelligent Routing: Smart Stackers utilize advanced navigation systems and algorithms to optimize travel routes within the warehouse. They can select the most efficient paths to reach the desired storage locations, reducing travel time and maximizing productivity. This efficient routing minimizes unnecessary movements and contributes to space optimization.

5. Automated Palletizing: Smart Stackers can automate the palletizing process, ensuring that items are stacked in a stable and space-efficient manner on pallets. They can calculate optimal pallet configurations, including weight distribution and stability considerations, to maximize space utilization while maintaining load integrity.

6. Real-time Inventory Management: Smart Stackers are often integrated with warehouse management systems (WMS) or inventory management software. This integration allows for real-time tracking of inventory levels and locations. By providing accurate inventory information, Smart Stackers enable better decision-making for space allocation and storage optimization.

By employing these space optimization strategies, Smart Stackers contribute to maximizing the storage capacity of warehouses, improving inventory management, and increasing overall operational efficiency.