Products

Ebil Tech

Automatic Stacker

Automatic Stacker is one of our products, we can provide one-stop storage system solutions and products, our products also include Industrial Lift, Cassette Drawer Rack, Four-Directional Shuttle Racking System, Very Narrow Aisle Pallet Racking, Heavy Duty Pallet Rack, Steel Mezzanine Platform, FIFO Racking, Heavy Duty Racking System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Genoa (Italy), Izmir (Turkey), Birmingham (UK), Australia, Vietnam, Afghanistan, and so on. We are looking forward to cooperate with you. If you are interested in Automatic Stacker.

An Automatic Stacker, also known as an Automated Stacking Crane (ASC) or automated storage and retrieval system (AS/RS) Stacker, is a type of material handling equipment used to automate the stacking and retrieval of goods in a warehouse or distribution center. It is designed to efficiently handle palletized or unitized loads and optimize storage space utilization.

Automatic Stackers provide several benefits, including increased storage capacity, improved operational efficiency, reduced labor costs, enhanced inventory control, and optimized material flow. By automating the stacking and retrieval processes, these stackers contribute to streamlined warehouse operations, faster order fulfillment, and improved overall productivity.

Here are some key features and functionalities of an Automatic Stacker:

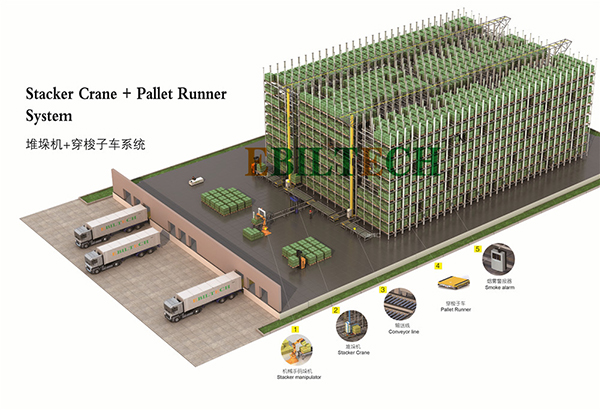

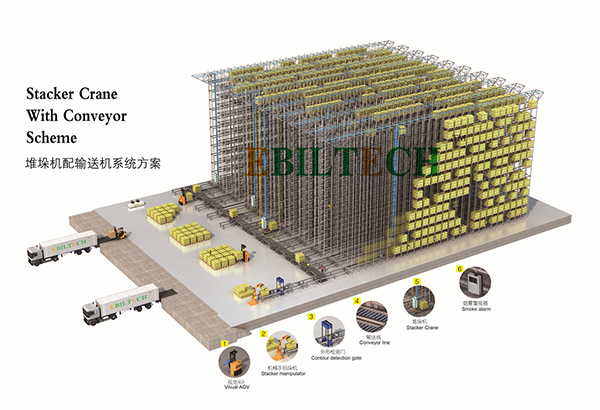

1. Stacking and Retrieval: The Automatic Stacker is capable of autonomously stacking and retrieving palletized or unitized loads from various storage locations, such as racks, shelves, or conveyor systems. It can lift, transport, and position loads with precision.

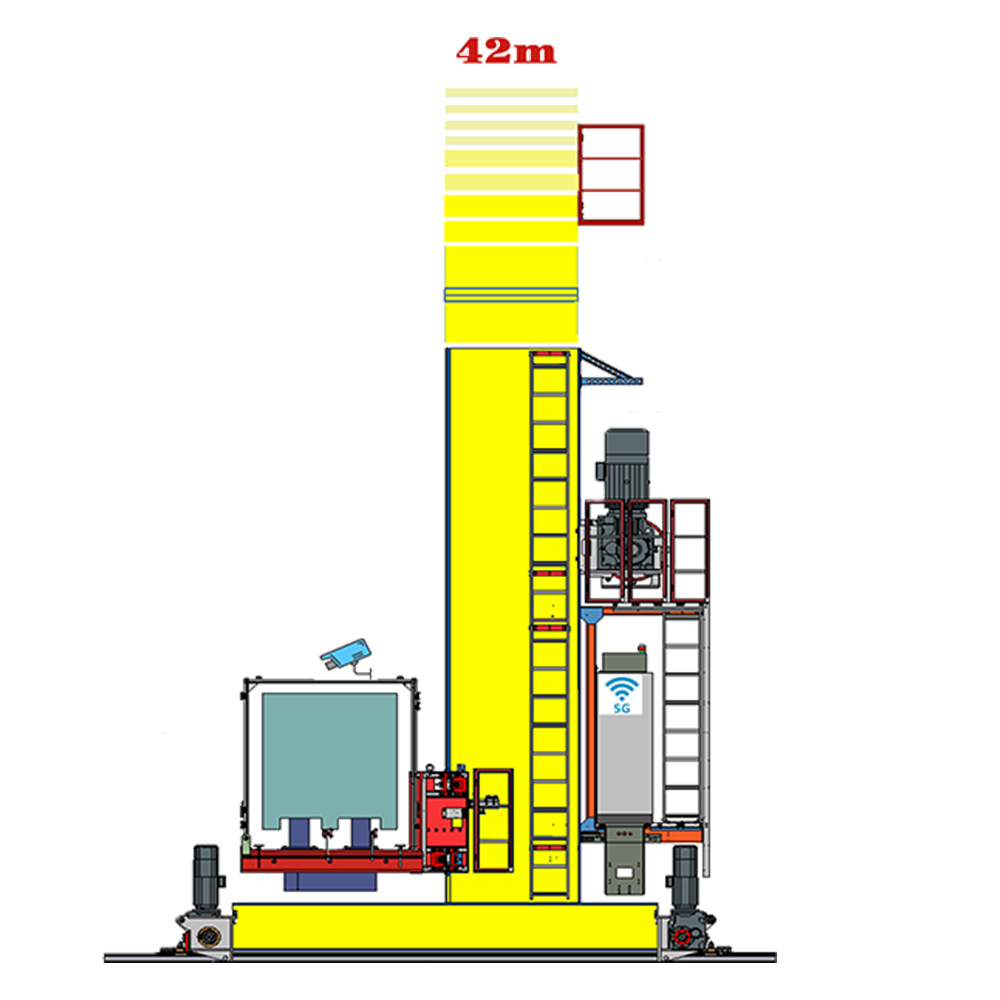

2. Vertical Movement: Automatic Stackers are equipped with vertical lifting capabilities to access multiple levels of storage. They can move up and down the height of the warehouse, allowing for high-density storage and efficient use of vertical space.

3. Load Capacity: Automatic Stackers are designed to handle different load capacities, ranging from a few hundred kilograms to several tons. The load capacity depends on the specific model and configuration of the stacker.

4. Autonomous Operation: Automatic Stackers operate autonomously, guided by a central control system. They follow predefined paths or instructions, navigating through the warehouse to access storage locations and retrieve or stack loads. The control system optimizes the movements and coordinates the operations of multiple stackers within the facility.

5. Integration with Warehouse Management Systems: Automatic Stackers integrate with Warehouse Management Systems (WMS) or Warehouse Control Systems (WCS). This integration enables real-time inventory management, order processing, and optimization of storage and retrieval operations. It facilitates efficient coordination between the stackers and other material handling equipment within the warehouse.

6. Safety Features: Automatic Stackers incorporate various safety features to ensure the safety of workers and the goods being handled. These features may include sensors, cameras, or proximity detectors to detect obstacles, emergency stop buttons, and safety protocols to prevent accidents.

7. Speed and Accuracy: Automatic Stackers offer fast and accurate stacking and retrieval operations. They can work at high speeds, reducing cycle times and improving productivity. The automated nature of the stacker minimizes human errors and ensures precise positioning of loads.

8. Scalability and Flexibility: Automatic Stackers are designed to be scalable and flexible, allowing for easy adaptation to changing storage needs and business requirements. Additional stackers can be added, and the system can be expanded or reconfigured to accommodate increased load volumes or changing warehouse layouts.