Products

Ebil Tech

Standard Pallet Racking

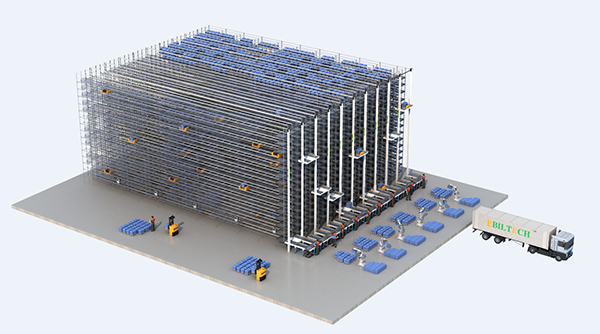

Standard Pallet Racking is one of our products, we can provide one-stop storage system solutions and products, our products also include Multi Shuttle Pallet Rack, Rail Guided Vehicle, Heavy Duty Racking, Beam Rack, Mechanical Mobile Shelving System, Storage Racks For Warehouse, Cargo Elevator, Roller Flow Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Wake Island, Georgia, Sofia (Bulgaria), Ceuta, Dakar (Senegal), Karelia, and so on. We are looking forward to cooperate with you. If you are interested in Standard Pallet Racking.

Standard pallet racking, also known as selective pallet racking, is a widely used storage system in warehouses and distribution centers. It provides direct access to each pallet stored in the system, allowing for efficient inventory management and easy retrieval of specific items. Here's some information about standard pallet racking:

1. Design and Components:

- Uprights: The upright frames are vertical columns that provide the main support for the pallet racking system. They are typically made of durable steel and are available in various heights, depths, and load-bearing capacities.

- Beams: Horizontal load beams connect the upright frames and create shelf levels for pallet placement. The beams are adjustable and can be positioned at different heights to accommodate different pallet sizes and load capacities.

- Connectors and Safety Pins: Connectors and safety pins secure the beams to the upright frames, ensuring stability and load-bearing capacity.

2. Key Features:

- Accessibility: Standard pallet racking offers direct access to each pallet, allowing for easy loading and unloading using forklifts or other material handling equipment. It facilitates efficient inventory management, as specific pallets can be easily located and retrieved.

- Versatility: Standard pallet racking is compatible with various pallet sizes and weights, making it suitable for a wide range of products and industries.

- Space Utilization: The vertical design of pallet racking maximizes the use of available vertical space, allowing for efficient storage while minimizing the footprint on the warehouse floor.

- Flexibility: Standard pallet racking can be easily adjusted and reconfigured to accommodate changes in storage requirements. The beam levels can be added, removed, or adjusted to accommodate different pallet heights or reorganize the storage layout.

3. Advantages:

- Selectivity: Each pallet can be accessed directly without the need to move or reposition other pallets, providing easy access to specific inventory items.

- Efficient Space Utilization: Standard pallet racking maximizes vertical storage space, allowing warehouses to store a large number of pallets in a relatively small footprint.

- Flexibility and Scalability: The adjustability and reconfigurability of the system make it adaptable to changing storage needs and future expansion.

- Compatibility: Standard pallet racking is compatible with a wide range of forklifts and material handling equipment, allowing for seamless integration with existing warehouse operations.

4. Considerations:

- Load Capacity: The load capacity of the pallet racking system depends on factors such as the quality of the uprights, beams, and connectors, as well as the configuration and layout of the system. It is important to ensure that the racking system is designed and installed to support the weight of the stored pallets.

- Safety Measures: Implementing proper safety measures, such as using rack protection accessories (e.g., column guards, end row protectors) and adhering to load capacity guidelines, is crucial to prevent accidents and injuries.

- Regular Inspections: Routine inspections should be conducted to identify any signs of damage, wear, or component failure. Damaged or worn components should be replaced promptly to maintain the safety and integrity of the system.

- Warehouse Layout: The layout of the warehouse should consider aisle width requirements and provide adequate space for the safe movement of forklifts and personnel.

When considering standard pallet racking for a warehouse, it is important to assess your specific storage needs, including pallet sizes, inventory turnover, available space, and future growth plans. Consulting with rack system suppliers or warehouse design experts can help determine the most suitable configuration and layout of the pallet racking system for your requirements, ensuring optimal storage efficiency and safety.