Products

Ebil Tech

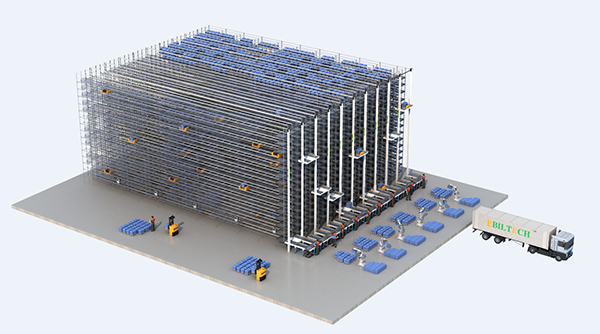

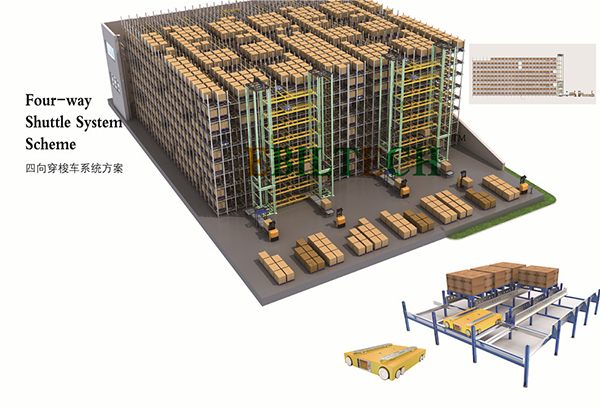

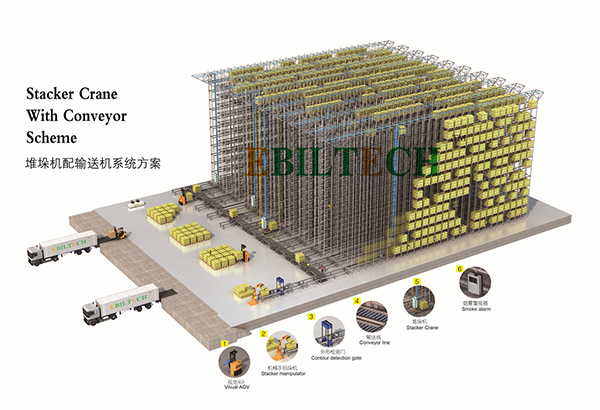

Four Way Shuttle

Four Way Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Pallet Flow Rack System, Pallet Flow Racking System, Automatic Stacker, Roll Out Sheet Metal Rack, Electric Mobile Shelving Systems, Tear Drop Pallet Rack, Guided Automated Vehicle, Roadway Single Column Stacker, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Latvia, Yemen, Lausanne (Switzerland), Kigali (Rwanda), Hungary, Phoenix (United States), and so on. We are looking forward to cooperate with you. If you are interested in Four Way Shuttle.

A four-way shuttle, also known as a four-way pallet shuttle or four-way pallet mover, is an automated material handling system designed to transport and store pallets within a warehouse or distribution center. It is a specialized type of shuttle system that provides versatility in handling pallets in multiple directions.

Functions of four way shuttle

1. Pallet Storage and Retrieval: The primary function of a four-way shuttle is to store and retrieve pallets within a racking system. It can autonomously transport pallets to designated storage locations, as well as retrieve them when needed for order fulfillment or other purposes.

2. Multi-Directional Movement: A four-way shuttle is designed to move in all four directions: forward, backward, left, and right. This enables it to access pallets from any side, providing flexibility in pallet handling and efficient utilization of storage space.

3. Vertical Storage Capabilities: Many four-way shuttle systems are equipped with lift mechanisms, allowing them to raise and lower pallets to different levels within the racking system. This vertical storage capability optimizes space utilization in warehouses with high ceilings.

4. High-Density Storage: Four-way shuttles are often employed in high-density storage environments. They can navigate narrow aisles and efficiently maneuver within the racking system, maximizing storage capacity and enabling high-density pallet storage.

5. Inventory Management: Four-way shuttle systems can be integrated with warehouse management systems and inventory control software. This integration allows for accurate tracking of pallets, real-time inventory updates, and efficient management of stock levels.

6. Order Picking Support: In warehouses that utilize order picking processes, four-way shuttles can assist in retrieving the required pallets for order fulfillment. They can transport the pallets to picking stations or conveyor systems, facilitating the picking and packing operations.

7. Cycle Time Reduction: By automating pallet handling tasks, four-way shuttle systems help reduce cycle times in warehouse operations. They can swiftly move pallets between storage locations and workstations, minimizing delays and optimizing workflow efficiency.

8. Safety and Reliability: Four-way shuttles are designed with safety features, such as sensors and collision avoidance systems, to ensure safe operation in the warehouse environment. They offer reliable performance, reducing the risk of errors and disruptions in pallet handling processes.

9. Integration with Warehouse Systems: Four-way shuttle systems can be seamlessly integrated with other warehouse systems and technologies, such as conveyor systems, robotic palletizers, or automated guided vehicles (AGVs). This integration enables streamlined material flow and enhanced operational efficiency.

10. Scalability and Flexibility: Four-way shuttle systems can be scaled up or down to accommodate changing operational needs. Additional shuttles can be added to the system as the warehouse expands, providing flexibility and adaptability to evolving requirements.

Certainly! Here are some additional functions and capabilities of a four-way shuttle system:

11. Multiple Pallet Handling: Four-way shuttles can handle multiple pallets simultaneously, depending on their design and configuration. This capability enables efficient movement of multiple pallets within the warehouse, reducing cycle times and increasing throughput.

12. Interoperability: Four-way shuttle systems can often integrate with existing warehouse infrastructure, such as pallet racking systems, conveyors, or automated storage and retrieval systems (AS/RS). This interoperability allows for seamless incorporation of the shuttle system into the overall material handling setup.

13. Dynamic Storage Allocation: Four-way shuttles can dynamically allocate storage locations based on the availability of space within the racking system. They can optimize storage density by identifying empty slots and efficiently allocating pallets to available locations.

14. Remote Control and Monitoring: The operation of four-way shuttle systems can be controlled remotely through a centralized control system. Operators can monitor and manage the shuttle's movements, storage locations, and system performance from a control room or designated workstation.

15. Error Handling and Fault Detection: Four-way shuttles are equipped with error handling mechanisms and fault detection systems. They can detect and respond to anomalies, such as obstructions in the aisles, misalignments, or mechanical issues, ensuring smooth and reliable operation.

16. Energy Efficiency: Many four-way shuttle systems incorporate energy-saving features to optimize power consumption. They may have programmable sleep modes or energy management systems that help reduce energy usage during idle periods.

17. Real-Time Data and Analytics: Four-way shuttle systems can generate real-time data and provide valuable analytics related to pallet movements, storage utilization, and system performance. This data can be utilized for continuous improvement, optimizing operational efficiency, and identifying areas for optimization.

18. System Scalability: Four-way shuttle systems offer scalability to accommodate evolving business needs. Additional shuttles or components can be seamlessly added to expand the system's capacity and adapt to increased storage requirements or changing operational demands.

19. Maintenance and Diagnostics: Four-way shuttle systems often include diagnostic tools and maintenance features that facilitate routine inspections, error troubleshooting, and preventive maintenance. This ensures the system operates at peak performance and minimizes downtime.

20. Integration with Warehouse Control Systems (WCS): Four-way shuttle systems can integrate with Warehouse Control Systems to optimize material flow, coordinate tasks, and synchronize operations across different areas of the warehouse. This integration enhances overall efficiency and coordination within the warehouse environment.

These additional functions and capabilities of a four-way shuttle system contribute to the overall efficiency, productivity, and adaptability of modern warehouse operations. By automating and streamlining pallet handling processes, these systems help businesses optimize storage, improve throughput, and enhance overall operational effectiveness.

Components of four way shuttle

The components of a four-way shuttle system can vary depending on the specific design and manufacturer. However, here are the common components typically found in a four-way shuttle system:

1. Shuttle Device: The shuttle device is the main component of the system responsible for transporting and positioning pallets within the racking system. It is a self-powered unit equipped with wheels or rollers that enable it to move in all four directions. The shuttle device is designed to securely hold and carry pallets during transportation.

2. Power System: The four-way shuttle is powered by a battery or an electrical power source. The power system provides the necessary energy to drive the shuttle's movement and operate any additional features, such as lifting mechanisms or sensors.

3. Control System: The control system manages the operation and movement of the four-way shuttle. It can be integrated into the shuttle device itself or operate remotely through a centralized control station. The control system receives commands, monitors the shuttle's position, and ensures precise movements within the racking system.

4. Racking System: The racking system consists of specially designed pallet racking or shelving, which provides the structure and support for pallet storage. The racking system includes guide rails or tracks that allow the four-way shuttle to navigate within the storage lanes while maintaining stability and accuracy.

5. Lift Mechanism (Optional): Some four-way shuttle systems include a lift mechanism that enables the shuttle device to raise and lower pallets to different levels within the racking system. This feature allows for efficient vertical storage and retrieval of pallets, maximizing storage capacity.

6. Safety Features: Four-way shuttle systems are equipped with safety features to ensure safe operation within the warehouse environment. These features may include sensors for collision avoidance, emergency stop buttons, and safety barriers to prevent accidents and protect personnel and equipment.

7. Communication and Data Exchange: Four-way shuttle systems often incorporate communication capabilities to exchange data with other systems, such as Warehouse Management Systems (WMS) or Warehouse Control Systems (WCS). This communication enables real-time coordination, inventory tracking, and seamless integration with overall warehouse operations.

8. Sensors: Sensors are used to detect the shuttle's position, monitor the surrounding environment, and provide feedback for precise movement. These sensors can include proximity sensors, encoders, or optical sensors that assist in navigation, obstacle detection, and alignment.

9. User Interface: The four-way shuttle system may have a user interface for operators to interact with the system. This interface can include a control panel, touch screen, or software application that allows operators to monitor and control the shuttle's movements, access system status, and troubleshoot issues.

10. Maintenance and Diagnostic Tools: Four-way shuttle systems often include maintenance and diagnostic tools to facilitate routine inspections, error troubleshooting, and preventive maintenance. These tools can include diagnostic software, error logging systems, or built-in diagnostics for efficient system maintenance.

11. Charging Station: If the four-way shuttle system operates on batteries, it may include a charging station where the shuttle devices can dock and recharge their batteries. The charging station ensures that the shuttles have sufficient power for continuous operation.

12. Positioning System: A positioning system, such as RFID (Radio Frequency Identification) or barcode scanners, may be integrated into the four-way shuttle system. These systems help identify the exact location of the shuttle within the racking system, ensuring accurate positioning and retrieval of pallets.

13. Weight Sensors: Some four-way shuttle systems incorporate weight sensors to measure the weight of the pallets being transported. This information can be used for inventory management, load balancing, or monitoring weight limits within the racking system.

14. Emergency Stop System: An emergency stop system is included in the four-way shuttle system to immediately halt the shuttle's movements in case of an emergency or safety hazard. It can be activated through emergency stop buttons or sensors strategically placed throughout the system.

15. Lift Locking Mechanism: If the four-way shuttle system includes a lift mechanism, it may have a locking mechanism to secure the pallets during transportation and storage. The locking mechanism ensures that the pallets remain stable and prevent any unwanted movements.

16. Remote Monitoring and Control: Some four-way shuttle systems offer remote monitoring and control capabilities. This allows operators or supervisors to monitor and control the system's operation, access real-time data, and make adjustments remotely, enhancing operational efficiency and flexibility.

17. System Integration Interfaces: Four-way shuttle systems often provide interfaces or protocols to integrate with other warehouse systems, such as Warehouse Management Systems (WMS) or Material Handling Control Systems (MHCS). These interfaces enable seamless data exchange, coordination, and synchronization with other components of the warehouse operation.

18. Maintenance and Service Access Points: The four-way shuttle system may have designated access points or panels to facilitate maintenance and servicing tasks. These access points provide convenient entry to components, wiring, and mechanical parts for inspections, repairs, or component replacement.

19. Software and Firmware: Four-way shuttle systems utilize software or firmware to control and manage the operation of the shuttle devices. This software may include algorithms for path planning, optimization, and coordination with other warehouse processes.

20. Documentation and Manuals: Manufacturers of four-way shuttle systems typically provide documentation and manuals that contain information on installation, operation, maintenance, troubleshooting, and safety guidelines. These resources assist warehouse personnel in understanding and effectively utilizing the system.

It's important to note that the specific components and features of a four-way shuttle system can vary depending on the manufacturer, system configuration, and individual requirements of the warehouse or distribution center.