Products

Ebil Tech

Storage Pallet Racking

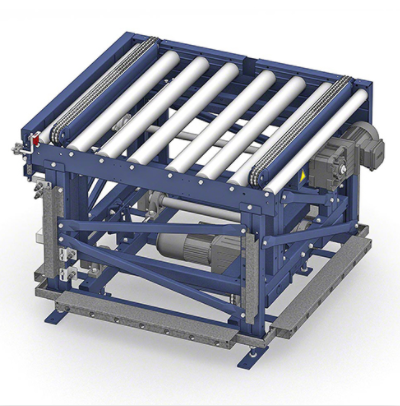

Storage Pallet Racking is one of our products, we can provide one-stop storage system solutions and products, our products also include Four-Way Shuttle Racking System, Honeycomb Rack Starr, Racking System Equipment Mezzanine, Industrial Radio Shuttle Racking, Automated Guided Transport, Medium-Duty Rack, Mobile Shuttle Carrier, Honeycomb Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Navassa Island, Niue, Bangkok (Thailand), Tirana (Albania), Australia, Turin (Italy), and so on. We are looking forward to cooperate with you. If you are interested in Storage Pallet Racking.

Storage pallet racking, also known as pallet racking or pallet rack system, is a type of storage solution designed to store and organize palletized goods in a warehouse or distribution center. It provides a framework of vertical frames and horizontal beams to create multiple levels or tiers where pallets can be stored.

Here are the key features and components of a storage pallet racking system:

1. Upright Frames: Upright frames, also called vertical frames or uprights, are the vertical columns that form the main support structure of the racking system. These frames are typically made of steel and are anchored to the floor for stability. They provide the vertical support and stability for the overall structure.

2. Horizontal Beams: Horizontal beams, also known as cross beams or load beams, are attached to the upright frames to create the levels or tiers where pallets are placed. These beams are adjustable and can be moved up or down along the frames to accommodate different pallet sizes and heights.

3. Pallet Supports: Pallet supports, also called wire mesh decking or pallet decking, are optional components that can be added to the racking system. They provide additional support and stability for the pallets, ensuring that they are properly positioned and reducing the risk of sagging or damage.

4. Load Capacity: Storage pallet racking systems are designed to withstand the weight of palletized goods. The load capacity will depend on the specific design and configuration of the racking system, as well as the quality of materials used.

5. Selective Access: Pallet racking systems are typically designed for selective access, meaning that each pallet position is individually accessible. This allows for easy retrieval of any pallet without the need to move other pallets, providing flexibility in inventory management and order fulfillment.

6. Safety Features: To ensure safety, storage pallet racking systems often include safety features such as row spacers, column protectors, and load stoppers, which help prevent accidents, protect the racking structure, and ensure the safety of personnel operating within the warehouse.

Storage pallet racking systems come in various configurations, including selective rack systems, drive-in rack systems, push-back rack systems, and more. The choice of the system depends on factors such as the type of goods being stored, the warehouse layout, accessibility requirements, and desired storage density.

It's important to consider the load-bearing capacity, safety regulations, and the specific needs of the operation when selecting and installing a storage pallet racking system. Consulting with a professional rack supplier or a warehouse layout expert is advisable to ensure the right choice and proper installation for a specific application.