Products

Ebil Tech

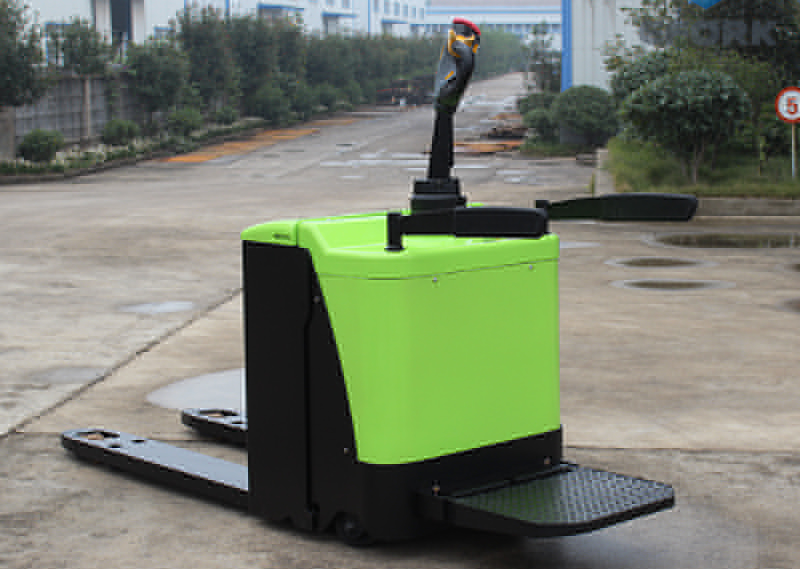

Industrial Shuttle Car

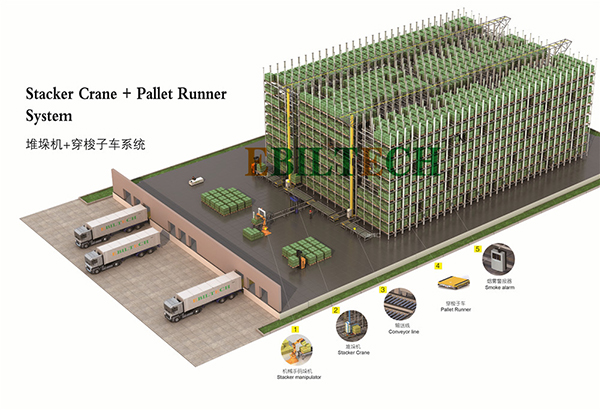

Industrial Shuttle Car is one of our products, we can provide one-stop storage system solutions and products, our products also include Automatic Radio Shuttle, Mezzanine Rack System, Intelligent Stacker Crane, Teardrop Warehouse Rack, Multi-Storey Shuttle Car, Material Handling Shuttle Car, High-Density Racking System, Cassette Drawer Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Eritrea, Canberra (Australia), Mali, Singapore (Singapore), Chile, Luanda (Angola), and so on. We are looking forward to cooperate with you. If you are interested in Industrial Shuttle Car.

An industrial shuttle car, also known as a shuttle car or shuttle vehicle, is a specialized transport vehicle commonly used in mining operations, particularly in underground mines. It is designed to efficiently move materials, such as coal or ore, from the working face to a designated location for further processing or transportation.

The key features and characteristics of an industrial shuttle car:

1. Load Capacity: Industrial shuttle cars are built to handle heavy loads of material. They typically have a large carrying capacity, allowing them to transport significant amounts of coal, ore, or other materials in a single trip.

2. Compact Size: Shuttle cars are designed to operate in confined spaces, particularly in underground mine tunnels. They have a compact size, allowing them to maneuver easily in tight areas and navigate through narrow passages.

3. Tracked or Wheeled: Shuttle cars can be equipped with either tracks or wheels, depending on the specific requirements of the mine and the conditions of the underground environment. Tracked shuttle cars offer better traction and stability on uneven surfaces, while wheeled shuttle cars provide more flexibility in terms of movement.

4. Loading Mechanism: Industrial shuttle cars are typically equipped with a loading mechanism, such as a conveyor or a hydraulic system, that allows them to receive materials directly from the mining equipment or from the mining face. This mechanism enables efficient and continuous loading of materials onto the shuttle car.

5. Operator Cabin: Shuttle cars usually have an enclosed operator cabin or control station where the operator can control the vehicle's movement, loading, and dumping operations. The cabin provides a comfortable and safe environment for the operator while they navigate the mine and handle materials.

6. Dumping Mechanism: Once the shuttle car reaches the designated location, it can discharge its load through a dumping mechanism. This mechanism may include a tipping or bottom-dump mechanism that allows the materials to be unloaded in a controlled manner.

Industrial shuttle cars play a crucial role in underground mining operations by facilitating the transportation of materials from the mining face to the surface or to other processing areas within the mine. They enhance the efficiency of material handling, reduce the reliance on manual labor, and contribute to increased productivity in mining operations.

The specific design, features, and capacities of industrial shuttle cars may vary among manufacturers and depend on the specific requirements of the mine and the type of material being transported.