Products

Ebil Tech

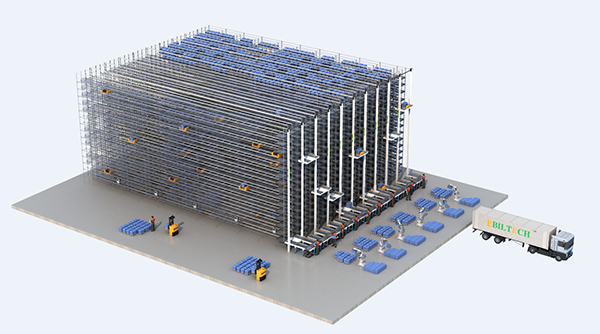

Multi-Storey Shuttle Car

Multi-Storey Shuttle Car is one of our products, we can provide one-stop storage system solutions and products, our products also include Pull Out Sheet Storage, Guided Transport Vehicle, Automated Shuttle Rack, Telescoping Arm Rack, Multi-Directional Shuttle Racking System, VNA Racking System, Medium-Sized Shelving, Industrial Lift, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Navassa Island, Perth (Australia), Palo Alto (United States), Palau, Denmark, Newcastle upon Tyne (UK), and so on. We are looking forward to cooperate with you. If you are interested in Multi-Storey Shuttle Car.

A Multi-Storey Shuttle Car, also known as a Multi-Level Shuttle System or Multi-Level Shuttle Car, is a type of material handling system used for high-density storage and retrieval of goods in multi-level or multi-story warehouses or distribution centers. It combines the capabilities of shuttle vehicles with a vertical movement mechanism to access and handle goods on different levels.

The features and components of a Multi-Storey Shuttle Car system:

1. Shuttle Car: The shuttle car is an autonomous vehicle that operates horizontally within the storage lanes of each level. It is designed to transport and handle goods, such as pallets or containers, within the storage system.

2. Vertical Movement Mechanism: The Multi-Storey Shuttle Car system incorporates a vertical movement mechanism, such as lifts, elevators, or vertical conveyors, to enable the shuttle car to move between different levels or stories of the facility. This mechanism allows efficient access to goods stored on multiple levels.

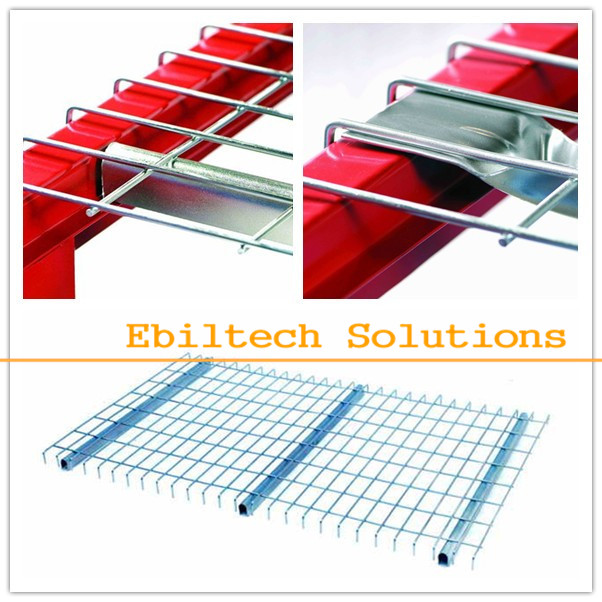

3. Storage Racks: The storage racks in a Multi-Storey Shuttle Car system are typically designed with multiple levels or tiers to maximize vertical space utilization. The shuttle car can move horizontally within the storage lanes of each level to access and retrieve goods.

4. Control System: The Multi-Storey Shuttle Car system is controlled by a centralized control system that manages the movements and operations of the shuttle cars and vertical movement mechanisms. The control system optimizes storage and retrieval tasks, coordinates the movements of the shuttle cars, and ensures efficient material handling operations.

5. Load Handling: The shuttle car within the Multi-Storey Shuttle Car system is equipped with mechanisms, such as forks or platforms, to handle and transport the goods. It can lift, lower, and position the pallets or containers within the storage positions on each level.

6. Communication and Integration: The shuttle cars and vertical movement mechanisms communicate with the central control system to receive instructions and provide real-time status updates. Integration with warehouse management systems (WMS) or inventory control systems allows for seamless coordination and information flow.

Multi-Storey Shuttle Car systems offer benefits such as increased storage capacity, efficient space utilization, improved productivity, reduced labor requirements, and enhanced inventory management in facilities with limited horizontal space but vertical height.

The specific features and functionalities of Multi-Storey Shuttle Car systems can vary among manufacturers and depend on the specific requirements of the facility.