Products

Ebil Tech

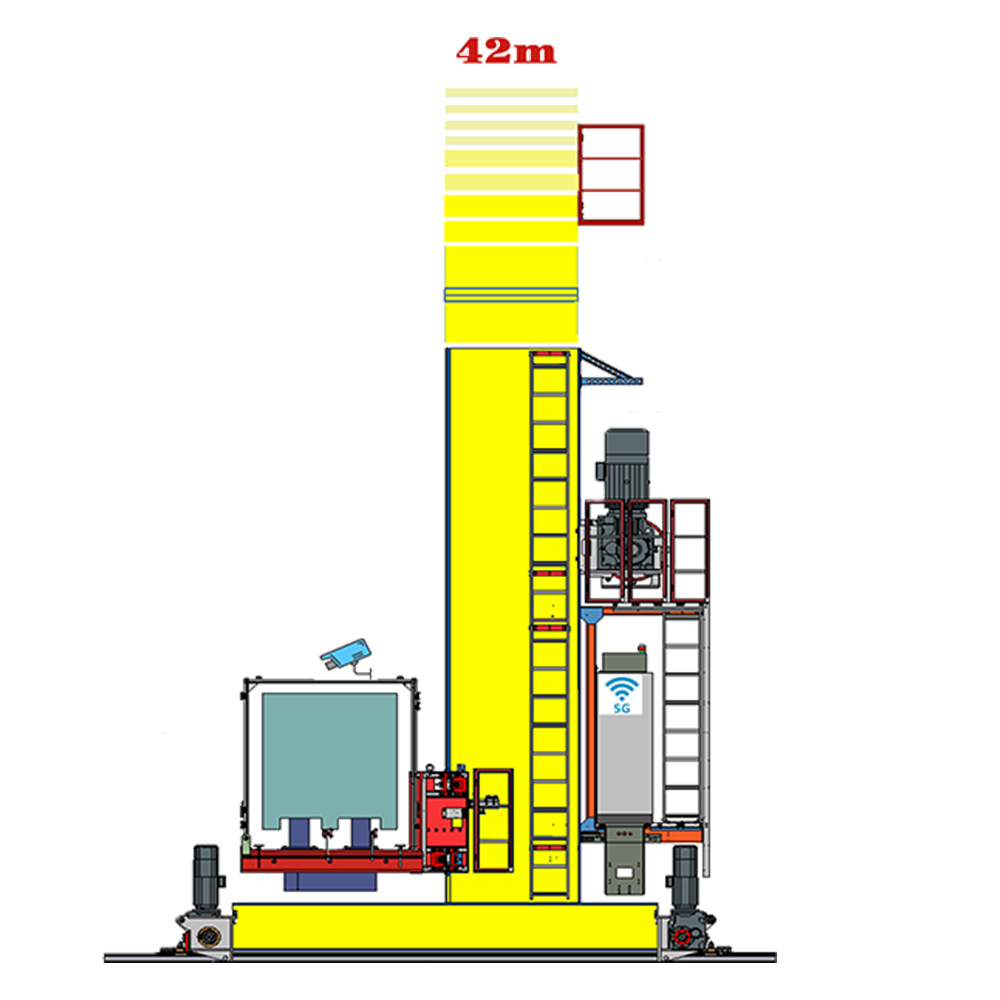

Robotic Shuttle

Robotic Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Steel Mezzanine Platform, Drive In Pallet Rack System, Telescopic arm storage rack, Medium-Duty Rack, Pallet Storage Rack, FIFO Racking, Medium-Duty Storage Rack, Intelligent Stacker, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Timor-Leste, Singapore (Singapore), Southampton (UK), Cincinnati (United States), Gaborone (Botswana), Pakistan, and so on. We are looking forward to cooperate with you. If you are interested in Robotic Shuttle.

The Robotic Shuttle is an autonomous or automated robotic system used for the transportation or movement of goods within a warehouse or distribution center. It combines the capabilities of a robotic system with the functionalities of a shuttle to optimize material handling operations.

A Robotic Shuttle typically consists of a robotic platform or vehicle equipped with sensors, cameras, and advanced navigation algorithms to operate autonomously or under centralized control. It can navigate through the facility, pick up goods, transport them to designated locations, and perform various tasks without constant human intervention.

Here are some key features and characteristics of a Robotic Shuttle:

1. Autonomy: Robotic Shuttles operate autonomously, relying on advanced technologies such as artificial intelligence, machine learning, and sensor fusion to perceive their environment, make decisions, and execute tasks without direct human intervention.

2. Navigation and Mapping: They use mapping and localization algorithms to create a map of the environment and determine their position within it. This allows them to plan optimal routes, avoid obstacles, and navigate efficiently through the facility.

3. Load Handling: Robotic Shuttles are equipped with mechanisms such as forks, conveyors, or platforms to handle and transport goods. They can pick up, move, and position items at specific locations within the warehouse.

4. Communication and Integration: Robotic Shuttles can communicate with a central control system, a warehouse management system (WMS), or other robotic systems. This enables coordination, task allocation, and information exchange to optimize material flow and overall warehouse operations.

5. Flexibility and Adaptability: They offer flexibility in terms of load types and sizes they can handle. Some models may have adjustable forks or modular designs to accommodate different goods and adapt to changing operational requirements.

6. Safety Features: Safety is a critical aspect of Robotic Shuttles. They are equipped with various safety mechanisms, including collision avoidance sensors, emergency stop buttons, and safety protocols to ensure the well-being of humans and goods in their vicinity.

Robotic Shuttles can contribute to increased efficiency, accuracy, and productivity in warehouse operations. They can streamline goods transportation, reduce manual labor, minimize errors, and optimize inventory management.

It's important to note that specific features, capabilities, and designs of Robotic Shuttles may vary among manufacturers and depend on the particular requirements and applications within a warehouse or distribution center.