Products

Ebil Tech

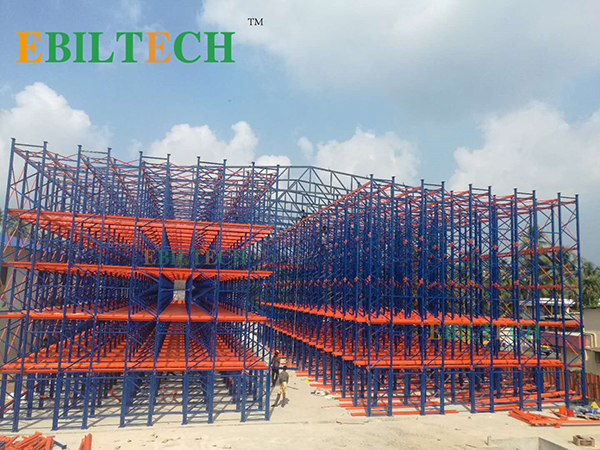

Drive In Pallet Rack System

Drive In Pallet Rack System is one of our products, we can provide one-stop storage system solutions and products, our products also include Drive In Pallet Rack, Intelligent Radio Shuttle, Steel Storage Platform, Telescopic Cantilever Rack, Adjustable cantilever rack, Heavy Duty Rack, Gravity Pallet Racking, Warehouse Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Ukraine, Quito (Ecuador), Bhutan, Ottawa (Canada), Karelia, Cook Islands, and so on. We are looking forward to cooperate with you. If you are interested in Drive In Pallet Rack System.

The drive-in pallet rack system is a type of high-density storage system designed to maximize storage capacity by reducing the number of aisles required. It is commonly used for storing large quantities of the same SKU or product.

In a drive-in pallet rack system, forklifts enter the rack structure to deposit or retrieve pallets. The system is configured with a series of lanes with no aisles between the racks. Pallets are loaded onto rails or guides that run the depth of the rack, allowing forklifts to drive directly into the rack structure.

Key features and characteristics of a drive-in pallet rack system include:

1. LIFO Inventory Rotation: Drive-in racks typically operate on a Last-In, First-Out (LIFO) inventory rotation system. Since the forklifts drive into the rack from one end, the last pallet loaded is the first to be retrieved. This makes it suitable for products with a longer shelf life or where strict inventory rotation is not necessary.

2. High-Density Storage: Drive-in rack systems offer high-density storage, as they eliminate the need for aisles between the rack bays. The system maximizes the use of available space, making it an efficient solution for warehouses with a large volume of identical products.

3. Structural Integrity: Drive-in racks are designed to withstand the load of forklifts driving into the structure. They are constructed with sturdy upright frames and horizontal load beams, providing reliable support for the pallets and maintaining the structural integrity of the system.

4. Load Capacity: The load capacity of a drive-in pallet rack system depends on factors such as the strength of the uprights, beams, and rail guides. It is important to adhere to the manufacturer's load capacity guidelines to ensure safe storage and prevent structural failure.

5. Limited Selectivity: Drive-in racks offer limited selectivity, as the forklifts must access the pallets from the same entry point. This means that pallets stored in the rear positions will need to be moved to access items stored deeper within the rack system.

6. Suitable for Bulk Storage: Drive-in racks are particularly suitable for storing large quantities of the same SKU, such as seasonal goods, raw materials, or products with a long shelf life. It is commonly used in industries like food and beverage, cold storage, and manufacturing.

7. Impact Resistance: Due to the nature of the system, drive-in racks are susceptible to forklift impacts. To mitigate damage, protective measures such as guide rail protectors or upright column protectors can be installed to safeguard the rack structure.

It is important to consider the specific requirements of the warehouse, including inventory turnover, accessibility, and load characteristics, when deciding whether a drive-in pallet rack system is the right choice. Consulting with experts can help determine if this type of system is suitable for your specific storage needs.