Products

Ebil Tech

Warehouse Automation Equipment

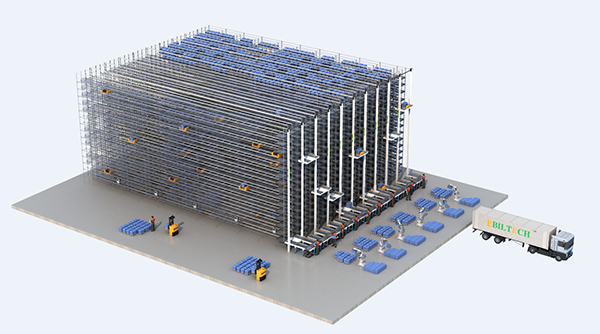

Warehouse Automation Equipment is one of our products, we can provide one-stop storage system solutions and products, our products also include Steel Mezzanine, Heavy Duty Rack, Electric Mobile Shelving, Multi-Directional Shuttle Racking System, High-Density Pallet Rack, Warehouse Rack System, Drive Through Rack, Automated Rail Vehicle, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Djibouti, British Indian Ocean Territory, Saint Lucia, Barcelona (Catalonia, Spain), Kabul (Afghanistan), Dakar (Senegal), and so on. We are looking forward to cooperate with you. If you are interested in Warehouse Automation Equipment.

Warehouse automation equipment refers to a wide range of machinery, systems, and technologies designed to automate various tasks and processes within a warehouse or distribution center. These equipment solutions are implemented to improve efficiency, increase productivity, reduce errors, and optimize overall operations. Here are some examples of warehouse automation equipment:

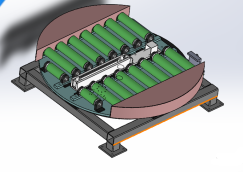

1. Conveyor Systems: Conveyor systems are used to transport goods or materials from one location to another within the warehouse. They consist of motorized belts, rollers, or chains that move items along designated paths. Conveyor systems can be customized to accommodate different load sizes, weights, and shapes.

2. Automated Guided Vehicles (AGVs): AGVs are robotic vehicles that navigate autonomously within the warehouse to transport goods or materials. They can be programmed to follow predefined routes, pick up and drop off items, and interact with other equipment or systems. AGVs are commonly used in material handling and order fulfillment operations.

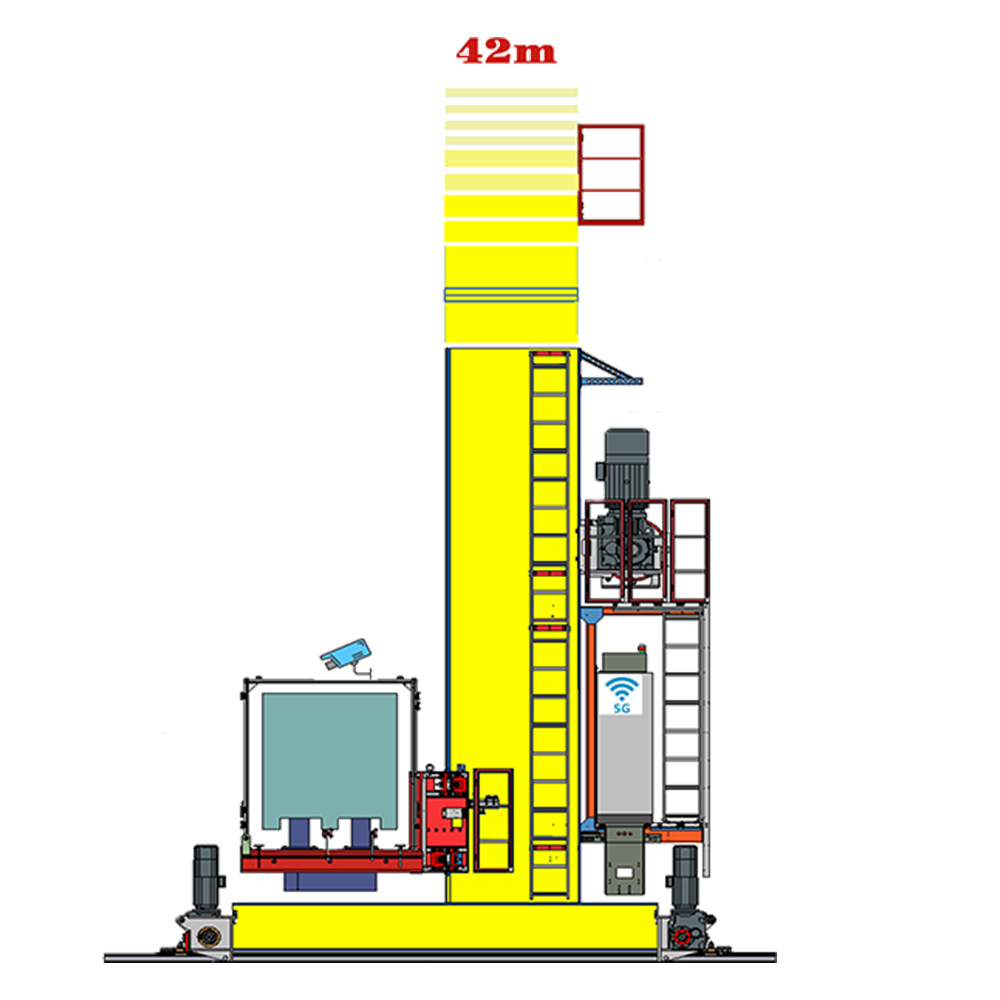

3. Automated Storage and Retrieval Systems (AS/RS): AS/RS systems are designed to automatically store and retrieve items from designated storage locations. They typically consist of vertical lift modules, stacker cranes, or robotic systems that handle the vertical movement of goods. AS/RS systems optimize storage density, minimize labor requirements, and enable efficient inventory management.

4. Pick-to-Light Systems: Pick-to-Light systems utilize light indicators and displays to guide warehouse personnel in the picking process. The system illuminates the location of the items to be picked and provides instructions, increasing accuracy and productivity in order fulfillment operations.

5. Robotic Picking Systems: Robotic picking systems employ robots equipped with advanced vision systems and robotic arms to perform picking tasks. These robots can identify, grasp, and handle items from bins, totes, or conveyors, automating the order fulfillment process and reducing the need for manual labor.

6. Sortation Systems: Sortation systems automate the process of sorting items based on predetermined criteria such as destination, size, or weight. They use conveyors, diverters, or automated chutes to route items to the appropriate location, improving order accuracy and throughput.

7. Automated Packaging Systems: Automated packaging systems automate the process of packaging goods for shipment. They can include equipment such as automated carton sealers, labelers, stretch wrappers, and packing robots. These systems streamline packaging operations, reduce labor requirements, and ensure consistent and efficient packaging quality.

8. Warehouse Management Systems (WMS): While not physical equipment, WMS software plays a crucial role in warehouse automation. WMS systems manage and control various aspects of warehouse operations, including inventory management, order fulfillment, task assignment, and optimization of equipment and resources.