Products

Ebil Tech

Storage Shuttle Car

Storage Shuttle Car is one of our products, we can provide one-stop storage system solutions and products, our products also include Beam Racking, VNA Pallet Racking System, Radio Shuttle Rack System, VNA Selective Rack, Robotic Storage Rack, Automated Warehouse, Mezzanine Racking System, Teardrop Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Perejil island, Virgin Islands, United States, Lagos (Nigeria), Syria, Ulaanbaatar (Mongolia), Christchurch (New Zealand), and so on. We are looking forward to cooperate with you. If you are interested in Storage Shuttle Car.

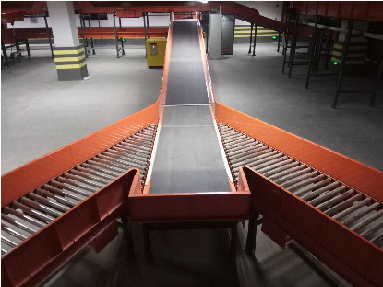

A Storage Shuttle Car, also known as an automated storage and retrieval system (AS/RS) Shuttle Car, is a type of automated material handling equipment designed for efficient storage and retrieval of goods in a warehouse or distribution center. The Storage Shuttle Car operates within a racking system and is responsible for transporting and positioning storage units, such as pallets or containers, within designated storage locations.

The Storage Shuttle Car system offers several benefits, including increased storage capacity, improved inventory management, reduced labor costs, and enhanced operational efficiency. It streamlines the storage and retrieval processes, optimizes space utilization, and allows for efficient material flow within the warehouse or distribution center.

Here are some key features and functionalities of a Storage Shuttle Car:

1. Automated Storage and Retrieval: The Storage Shuttle Car automates the process of storing and retrieving goods within a warehouse. It moves along predefined tracks or lanes within the racking system, accessing storage positions and delivering or retrieving storage units as required.

2. High-Density Storage: The Storage Shuttle Car system is designed to maximize storage density within the warehouse. It operates within a compact and vertically-oriented racking structure, allowing for efficient utilization of available space. The Shuttle Car can access multiple levels of the racking system, enabling high-density storage of goods.

3. Versatile Load Handling: The Shuttle Car is capable of handling different types of storage units, such as pallets, containers, or totes. It can be equipped with various types of grippers, clamps, or forks to securely hold and transport the load.

4. Integration with Warehouse Management Systems (WMS): The Storage Shuttle Car system is often integrated with a Warehouse Management System (WMS) or Warehouse Control System (WCS). This integration enables real-time inventory management, order processing, and optimization of storage and retrieval operations. It allows for efficient coordination between the Shuttle Car and other material handling equipment within the warehouse.

5. Fast and Accurate Operations: The Storage Shuttle Car offers fast and accurate storage and retrieval operations. It can quickly move along the designated tracks, accessing storage positions and delivering or retrieving storage units with precision. This helps to minimize cycle times and improve overall operational efficiency.

6. Scalability and Flexibility: The Storage Shuttle Car system is scalable and flexible, allowing for adjustments and expansions to accommodate changing storage needs or business requirements. The system can be easily reconfigured or expanded to adapt to evolving inventory levels or product mix.

7. Enhanced Inventory Control: The Storage Shuttle Car system provides enhanced inventory control and traceability. It can track and record the location of each storage unit within the racking system, ensuring accurate inventory management and facilitating efficient order fulfillment processes.