Products

Ebil Tech

Roadway Stacker Crane

Roadway Stacker Crane is one of our products, we can provide one-stop storage system solutions and products, our products also include Medium Duty Shelving, Rail-Bound Vehicle, VNA Warehouse Rack, Guided Transport Vehicle, Extendable Cantilever Rack, Drive In Racking, 4 Way Shuttle, Rail Guided Vehicle, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Saudi Arabia, Panama City (Panama), Chile, Mumbai (Maharashtra, India), Egypt, Czech Republic, and so on. We are looking forward to cooperate with you. If you are interested in Roadway Stacker Crane.

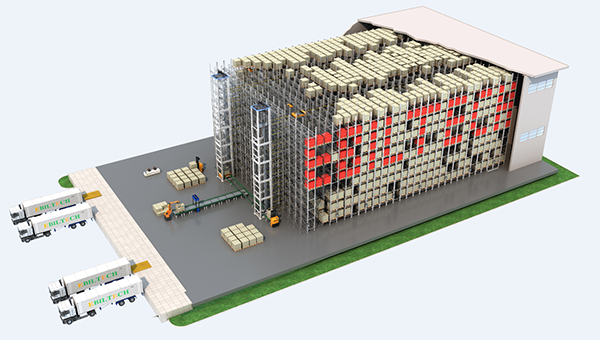

A roadway stacker crane, also known as an automated stacker crane or a stacker crane system, is a type of crane used in automated storage and retrieval systems (AS/RS) to handle and store palletized goods in high-rise warehouses. It is designed to operate on a roadway or rail system installed between the storage racks, enabling efficient and precise movement of pallets within the facility.

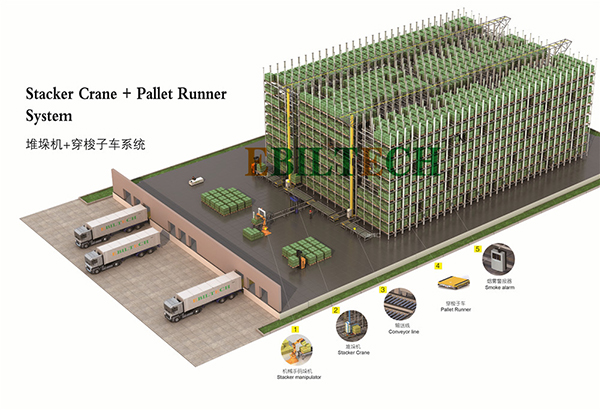

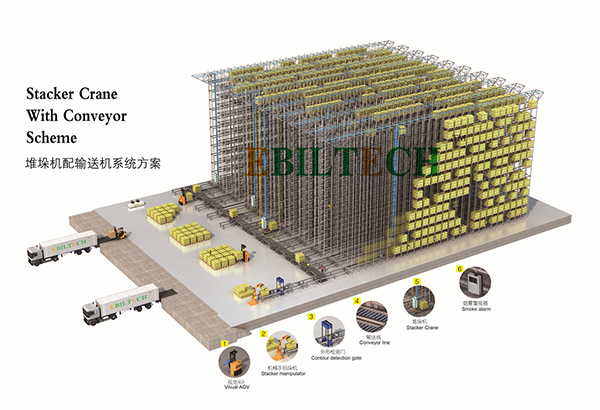

Roadway stacker cranes offer several advantages, including high storage density, fast and accurate handling of pallets, reduced labor requirements, and improved inventory management. They are commonly used in large-scale warehouses, distribution centers, and manufacturing facilities where efficient utilization of vertical space and automated material handling are essential.

The specific design and capabilities of a roadway stacker crane may vary depending on the manufacturer or system provider. Different companies may have their own proprietary technologies or variations under similar names.

Here are the key features and components of a roadway stacker crane:

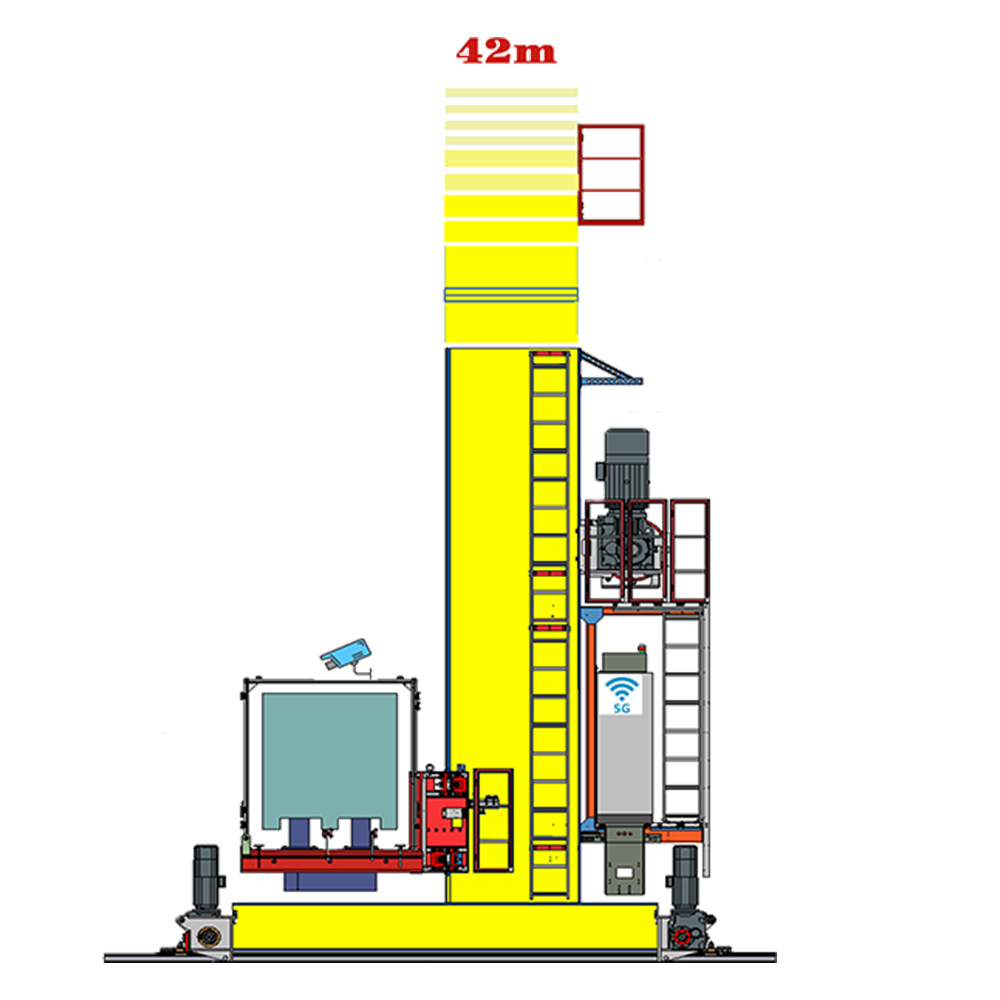

1. Crane Structure: A roadway stacker crane consists of a tall, vertical structure supported by columns or rails. The crane structure is typically equipped with a horizontal beam or bridge that spans across the storage racks. The beam supports the lifting mechanism and allows for horizontal movement along the roadway or rail system.

2. Lifting Mechanism: The crane is equipped with a lifting mechanism, often a telescopic mast or a fork assembly, that can raise and lower pallets. This mechanism allows for precise placement of pallets at specific storage locations within the rack structure.

3. Horizontal Movement: The roadway stacker crane is capable of horizontal movement along the roadway or rail system. It can move laterally along the storage racks, accessing multiple storage aisles and reaching different positions within the warehouse.

4. Automation and Control Systems: Roadway stacker cranes are typically automated and operated through a central control system or warehouse management system (WMS). The control system coordinates the movement and tasks of the stacker cranes, optimizing material flow, and ensuring efficient storage and retrieval operations.

5. Safety Features: Stackers cranes incorporate various safety features to ensure the protection of personnel and goods. These may include safety sensors to detect obstacles or obstructions, collision avoidance systems, emergency stop buttons, and safety zones to prevent unauthorized access to the crane's operating area.

6. Integration with AS/RS: Roadway stacker cranes are an integral part of an automated storage and retrieval system. They are integrated with other components, such as conveyor systems, automated guided vehicles (AGVs), or shuttle systems, to create a comprehensive and efficient material handling solution.