Products

Ebil Tech

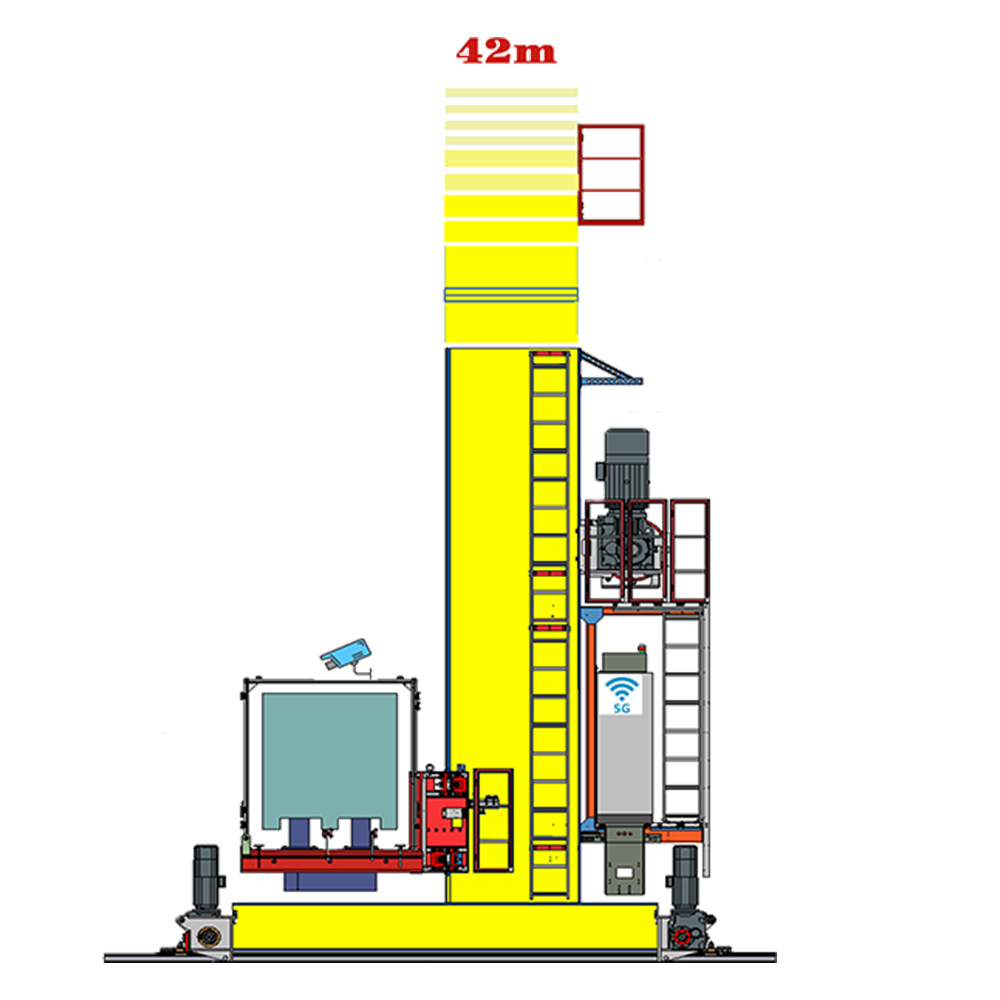

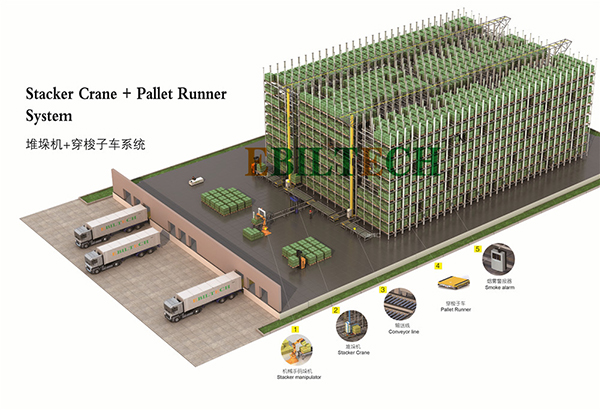

Storage Stacker

Storage Stacker is one of our products, we can provide one-stop storage system solutions and products, our products also include Tear Drop Pallet Rack, Tear Drop Pallet Shelving, Medium Duty Rack, RGV System, Racking Beam, Intelligent Radio Shuttle, High-Density Racking System, Shuttle Racking, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Sao Paulo (Sao Paulo State, Brazil), Haiti, Luxembourg City (Luxembourg), San Marino, Newcastle upon Tyne (UK), Papua New Guinea, and so on. We are looking forward to cooperate with you. If you are interested in Storage Stacker.

A Storage Stacker, also known as a Stacker Crane or Stacking Machine, is a type of automated material handling equipment used for the storage and retrieval of goods in high-rise storage systems, such as automated storage and retrieval systems (AS/RS) or pallet racking systems. It is designed to stack and retrieve items from various storage positions within a warehouse or distribution center.

The key features and characteristics of a Storage Stacker:

1. Vertical Movement: A Storage Stacker is capable of vertical movement along the height of the storage system. It can access multiple storage levels or tiers within the facility, allowing for efficient use of vertical space.

2. Load Handling: Storage Stackers are equipped with mechanisms, such as forks or platforms, to handle and transport goods. They can lift, lower, and position items, such as pallets or containers, within the storage positions.

3. Automated Operation: Storage Stackers are typically automated, operating under centralized control or following pre-programmed instructions. They can navigate through the storage system, locate specific storage positions, and perform storage or retrieval tasks autonomously.

4. Guidance System: To ensure precise movement and positioning, Storage Stackers utilize guidance systems. These systems can include rail tracks, guide wires, or optical sensors that help the stacker navigate and align with the storage positions.

5. Communication and Integration: Storage Stackers communicate with a central control system or warehouse management system (WMS). They receive instructions, provide real-time status updates, and integrate with other systems within the facility to optimize material flow and overall warehouse operations.

6. Safety Features: Safety is an important aspect of Storage Stackers. They are equipped with safety mechanisms, such as collision avoidance sensors, emergency stop buttons, and safety protocols, to ensure the safety of humans and goods in their vicinity.

Storage Stackers contribute to increased storage density, improved inventory management, and enhanced operational efficiency in warehouses or distribution centers. They can minimize manual labor requirements, reduce errors, and facilitate accurate and timely storage and retrieval of goods.

The specific features, capacities, and designs of Storage Stackers may vary among manufacturers and depend on the specific requirements and layout of the storage system.