Products

Ebil Tech

Pallet Storage Rack

Pallet Storage Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include High Density Mobile Shelving System, Warehouse Robot, long goods automated storage system, Warehouse Radio Shuttle, Miniload Stacker Crane, Pallet Flow Racking, Tear Drop Pallet Shelving, Drive In Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Quito (Ecuador), Malm? (Sweden), Kinshasa (Congo), Ethiopia, Bangalore (India), Kampala (Uganda), and so on. We are looking forward to cooperate with you. If you are interested in Pallet Storage Rack.

A Pallet Storage Rack, also known as a Pallet Racking System, is a type of storage system specifically designed for storing palletized goods. It provides a structured and efficient method of organizing and accessing large quantities of palletized products in a warehouse or distribution center.

Here are the types of Pallet Storage Racks commonly used in the industry:

1. Selective Pallet Racking: Selective Pallet Racking, as discussed earlier, allows for direct access to individual pallets. It is the most common type of pallet storage rack and provides high selectivity and flexibility in inventory management.

2. Drive-In and Drive-Through Racking: Drive-In and Drive-Through Racking systems are designed for high-density storage with fewer aisles. In these systems, pallets are stored on rails or beams that allow forklifts to drive directly into the rack structure. Drive-In Racking has a single entry point, while Drive-Through Racking has entry points on both ends, allowing for FIFO (First-In, First-Out) or LIFO (Last-In, First-Out) inventory rotation.

3. Push-Back Racking: Push-Back Racking systems are designed for high-density storage while maintaining selectivity. Pallets are stored on inclined carts or rails, and when a new pallet is loaded, it pushes the existing pallets back. When unloading, the pallets in the rear position are automatically moved forward for retrieval. This system allows for efficient use of space and provides greater selectivity compared to Drive-In Racking.

4. Pallet Flow Racking: Pallet Flow Racking systems are designed for high-density storage with FIFO inventory rotation. Pallets are loaded on one end of inclined roller tracks or wheels, and gravity moves them along the flow lanes to the unloading end. This system ensures automatic stock rotation and efficient order picking.

5. Cantilever Racking: Cantilever Racking is designed for the storage of long, bulky, or irregularly shaped items such as lumber, pipes, or furniture. It consists of vertical columns with horizontal arms that extend out to support the stored items. Cantilever Racking allows for easy access to individual items without the interference of vertical uprights.

6. Mobile Racking: Mobile Racking systems are mounted on mobile bases that can be moved laterally on tracks. This system maximizes storage capacity by eliminating the need for fixed aisles. Mobile Racking is suitable for operations where space is limited, and selectivity is not a primary concern.

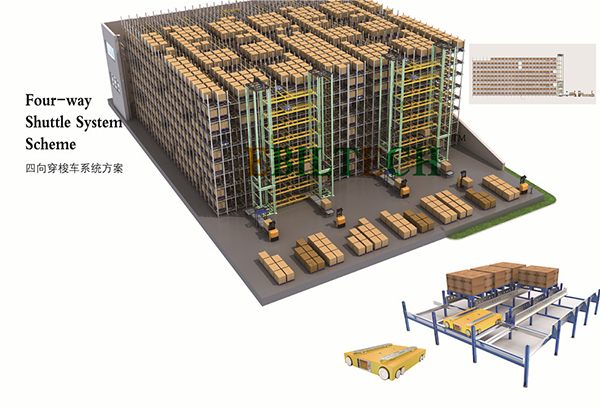

7. automated storage and retrieval systems (ASRS): ASRS combines a variety of automated technologies such as robotics, conveyors, and cranes to automatically store and retrieve pallets from designated locations. These systems are highly efficient and suitable for high-volume operations that require fast and precise handling.

Each type of Pallet Storage Rack offers unique advantages and is selected based on factors such as storage requirements, inventory rotation, available space, and handling equipment. The choice of the pallet storage rack system depends on the specific needs and goals of the operation.