Products

Ebil Tech

Drive In Pallet Racking

Drive In Pallet Racking is one of our products, we can provide one-stop storage system solutions and products, our products also include Pallet Racking System, Single Column Stacker Crane, Drive Through Racking, Teardrop Rack, Medium-Duty Racking System, Shuttle System, American Style Rack, Gravity Pallet Rack System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as India, Turin (Italy), Lusaka (Zambia), Baghdad (Iraq), Mali, Angola, and so on. We are looking forward to cooperate with you. If you are interested in Drive In Pallet Racking.

Drive-in pallet racking is a high-density storage system designed for the storage of homogeneous products that are stored on pallets and not time-sensitive, as it operates on a Last-In, First-Out (LIFO) principle. It is characterized by fewer aisles and deep lanes for the efficient utilization of available warehouse space.

Here are the key features and characteristics of drive-in pallet racking:

1. Structure: Drive-in pallet racking consists of upright frames and horizontal load beams that create deep lanes. The frames are placed close together, eliminating the need for individual aisles between each rack. The pallets are stored on rails or rails and guide channels within the racking structure.

2. LIFO Principle: Drive-in pallet racking operates on the Last-In, First-Out principle, meaning the last pallet loaded into a lane will be the first one retrieved. This makes it suitable for products with low turnover rates or when stock rotation is not a critical factor.

3. Deep Lane Storage: Drive-in racking allows for the storage of multiple pallets deep within each lane. Forklifts or reach trucks can drive directly into the lanes to place or retrieve the pallets. This deep lane storage maximizes the use of available space, as it eliminates the need for aisles between each rack.

4. High Storage Density: By eliminating individual aisles, drive-in pallet racking achieves high storage density. It optimizes the use of vertical space and allows for the storage of large quantities of the same SKU in a smaller footprint.

5. Load Considerations: Drive-in racking is suitable for products with a large quantity of the same SKU and a low number of different SKUs. It is important to consider the weight and stability of the loads, as the pallets in the rear may need to support the weight of the pallets in front.

6. Increased Space Utilization: Drive-in racking maximizes the use of space by minimizing unused areas. It is particularly useful in cold storage environments, where space is valuable and temperature control is critical.

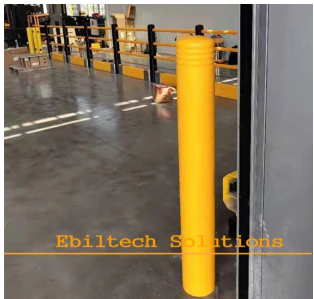

7. Safety Considerations: Safety measures such as floor guides, bumper rails, and column protectors are necessary to ensure safe operation and prevent damage to the racking system. Proper training for forklift operators is also essential to prevent accidents during pallet handling.

Drive-in pallet racking is commonly used in warehouses and distribution centers where stock rotation is not a priority and high-density storage is required. It offers efficient utilization of space, reduced operating costs, and increased storage capacity for homogeneous products. However, it may not be suitable for applications that require frequent access to individual pallets or necessitate a First-In, First-Out (FIFO) inventory management approach.