Products

Ebil Tech

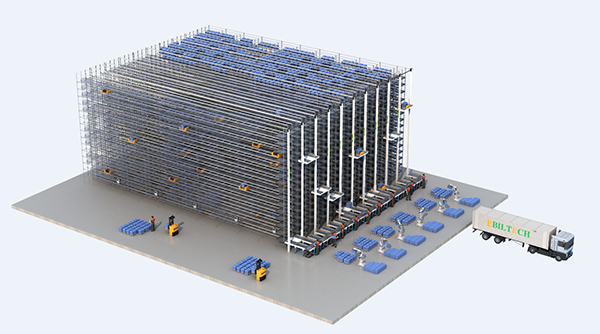

Box-Shuttle System

Box-Shuttle System is one of our products, we can provide one-stop storage system solutions and products, our products also include Industrial Steel Platform, Industrial Shuttle Car, Archive Shelving, Adjustable Arm Cantilever Rack, Goods Lift, Beam Racking System, Adjustable cantilever rack, Smart Rack System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Liverpool (UK), Oslo (Norway), Bristol (UK), Timor-Leste, Boston (Massachusetts, USA), Pridnestrovie, and so on. We are looking forward to cooperate with you. If you are interested in Box-Shuttle System.

A box-shuttle system, also known as a shuttle racking system, is a type of high-density storage system used in warehouses and distribution centers. It is designed to optimize space utilization and improve the efficiency of goods storage and retrieval. The configuration and capabilities of box-shuttle systems can vary depending on the specific manufacturer and system design. The shuttle devices may differ in size, weight capacity, and control mechanisms. It's recommended to consult with experts or system providers to determine the best box-shuttle system for a particular warehouse or distribution center.

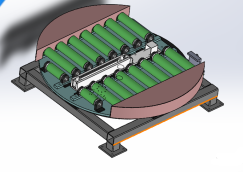

In a box-shuttle system, storage racks are equipped with specialized shuttle devices that move horizontally within the rack structure. The shuttle devices, also called shuttles or carriers, are battery-powered and controlled remotely. They can transport individual storage containers or pallets within the racking system, accessing different levels and positions.

Here's how a box-shuttle system typically works:

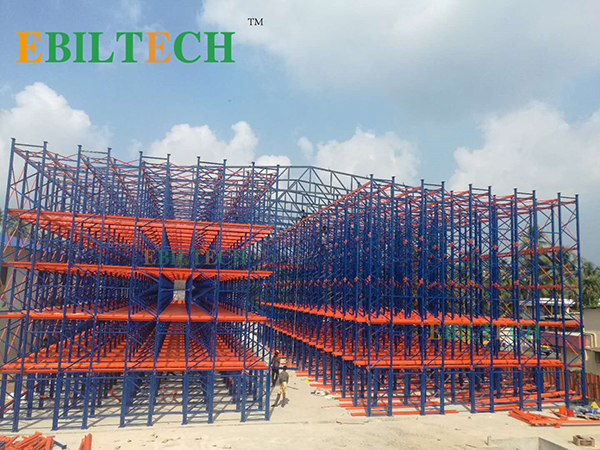

1. Rack Structure: The box-shuttle system consists of a series of racks with multiple levels. The racks are designed to accommodate storage containers or pallets, which are placed on the rack beams.

2. Shuttle Devices: Each level of the rack structure is equipped with shuttle devices. These shuttles are placed on the rack beams and can move horizontally along the length of the rack. They are controlled by an operator or an automated system.

3. Loading and Unloading: Goods are loaded onto the shuttles either manually or with the help of forklifts or conveyor systems. The shuttles then transport the goods to the designated storage location within the rack structure.

4. Storage and Retrieval: The shuttles store the goods in the designated position within the rack structure. When goods need to be retrieved, the shuttles locate the specific item and transport it to the retrieval point, where it can be picked up by an operator or another automated system.

Benefits of a box-shuttle system include:

1. Increased Storage Density: The shuttle system allows for high-density storage as it optimizes the use of vertical and horizontal space within the rack structure. It can accommodate a large number of storage containers or pallets in a compact area.

2. Efficient Goods Retrieval: The shuttles can quickly locate and retrieve specific items from the storage racks, reducing the time and effort required for order picking or inventory retrieval.

3. Flexibility and Scalability: Box-shuttle systems can be customized and adapted to meet specific storage requirements. They can be easily expanded or reconfigured based on changing business needs.

4. Improved Warehouse Operations: The automated nature of the box-shuttle system reduces labor requirements and minimizes the risk of errors associated with manual handling. It enhances overall warehouse efficiency and throughput.