Products

Ebil Tech

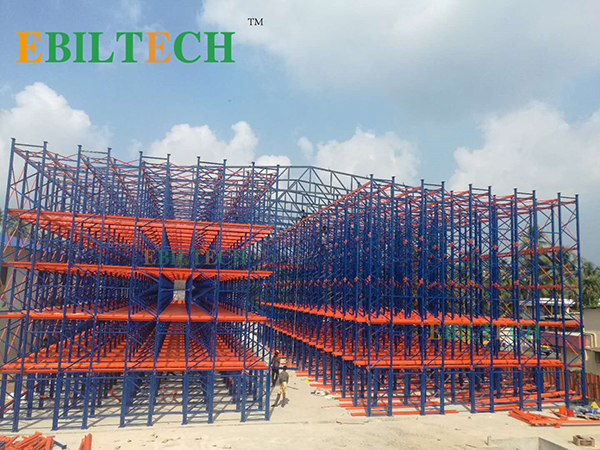

Heavy Duty Drive-In Pallet Rack

Heavy Duty Drive-In Pallet Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include Shuttle Robot, Multi Shuttle, Four Way Shuttle Rack, Mother Shuttle And Satellite Shuttle System, Adjustable cantilever rack, Industrial Radio Shuttle Racking, Heavy Duty Rack, Pallet Runner Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Guinea-Bissau, Switzerland, Miami (Florida, USA), Samoa, Sarajevo (Bosnia and Herzegovina), Nottingham (UK), and so on. We are looking forward to cooperate with you. If you are interested in Heavy Duty Drive-In Pallet Rack.

A Heavy Duty Drive-In Pallet Rack is a type of storage system designed for high-density storage of palletized goods. It is characterized by a configuration that allows forklifts or other material handling equipment to enter the rack structure and place pallets directly onto supporting rails, eliminating the need for individual beams or shelf levels. This design maximizes storage capacity by minimizing aisle space and is particularly useful for storing large quantities of the same SKU.

Here are the key features and applications of Heavy Duty Drive-In Pallet Racks:

Features of Heavy Duty Drive-In Pallet Rack:

1. Drive-In Design: Heavy Duty Drive-In Pallet Racks have a drive-in design, allowing forklifts to drive directly into the rack structure to deposit or retrieve pallets. This eliminates the need for aisles between racks, maximizing the use of available space.

2. LIFO Storage: The drive-in configuration follows a Last-In, First-Out (LIFO) storage method. This means that the last pallet loaded into the rack is the first one to be unloaded, making it suitable for goods that do not require strict chronological rotation.

3. Rail System: Instead of beams or shelves, Heavy Duty Drive-In Pallet Racks use horizontal rails or channels to support the pallets. These rails are typically designed to withstand heavy loads and are placed at different heights to accommodate multiple levels of pallet storage.

4. Load Capacity: Heavy Duty Drive-In Pallet Racks are designed to handle heavy loads. The load capacity depends on factors such as the strength of the rails, the upright frames, and the overall structural integrity of the rack system.

5. Customization: The configuration of Heavy Duty Drive-In Pallet Racks can be customized to accommodate specific pallet sizes and load capacities. The number of levels, the spacing between rails, and the depth of the rack structure can be tailored to fit the requirements of the stored goods.

6. Safety Measures: Safety measures such as guide rails, which help align the forklifts during entry and exit, can be installed to prevent accidental damage to the rack structure. Additionally, proper training and forklift operating procedures are crucial to ensure safe operation within the drive-in system.

Applications of Heavy Duty Drive-In Pallet Rack:

1. High-Density Storage: Heavy Duty Drive-In Pallet Racks are ideal for high-density storage of large quantities of the same product. By eliminating aisles, they maximize storage capacity and allow for efficient use of available space.

2. Cold Storage Facilities: Drive-in racks are commonly used in cold storage facilities, such as refrigerated warehouses or freezers. Their high-density design helps optimize space utilization in environments where temperature control is critical.

3. Bulk Storage: Drive-in racks are well-suited for storing bulk goods that are not time-sensitive and do not require frequent access. They are often used for storing seasonal items, raw materials, or finished products awaiting distribution.

4. Limited SKU: Heavy Duty Drive-In Pallet Racks are suitable when dealing with a limited number of SKUs. Since the LIFO storage method is used, it is important to consider the product's shelf life and inventory management requirements.

5. Manufacturing and Distribution: Drive-in racks are commonly utilized in manufacturing and distribution centers to store large quantities of raw materials, components, or finished goods. They facilitate efficient storage and retrieval of palletized items, reducing handling time and improving overall productivity.

It's essential to consider factors such as the weight and dimensions of the palletized goods, the available space, load capacity requirements, and any specific safety regulations when implementing Heavy Duty Drive-In Pallet Racking. Consulting with professionals experienced in drive-in rack design and installation is recommended to ensure a safe and efficient storage solution tailored to your specific needs.