Products

Ebil Tech

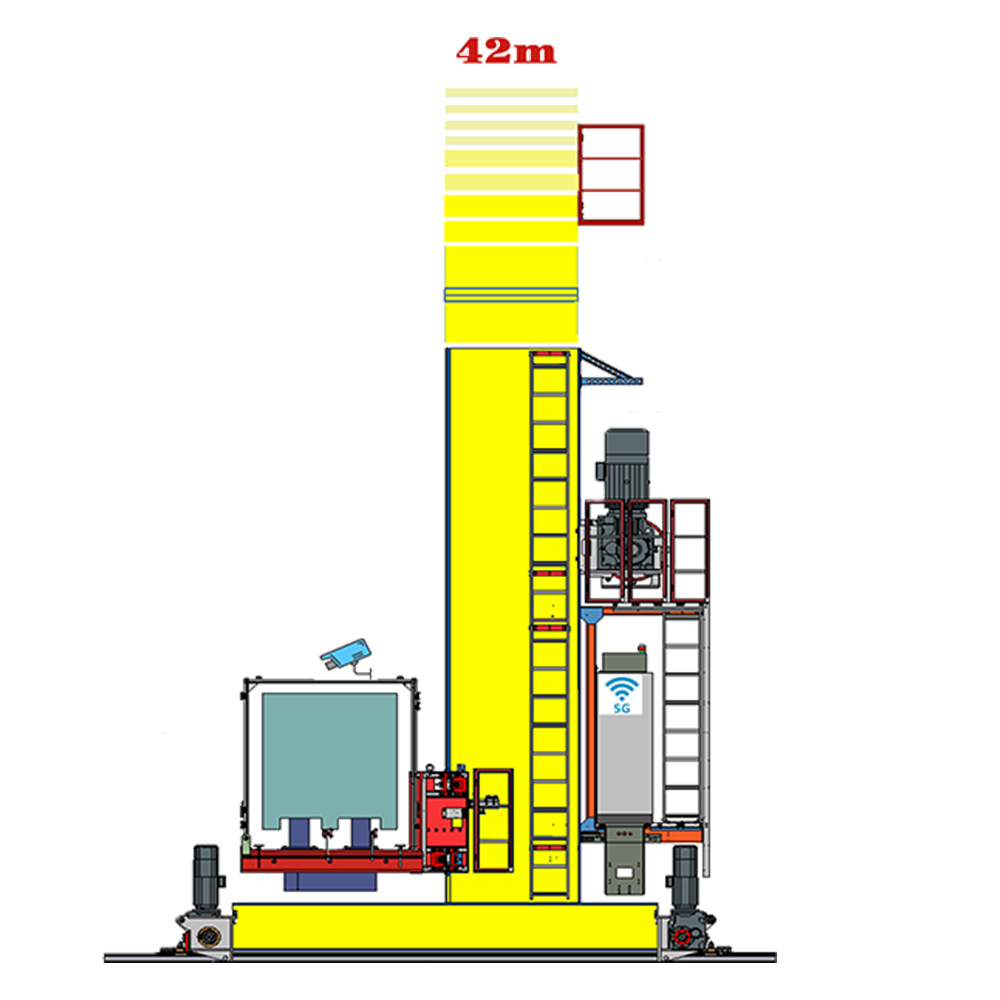

Shuttle Robot

Shuttle Robot is one of our products, we can provide one-stop storage system solutions and products, our products also include Warehouse Equipment, Telescoping Cantilever Racking System, Garment Storage Shelving, Electrically Operated Mobile Shelves, Automated Mobile Storage System, Extendable cantilever rack, Drive Through Rack, Multi-Directional Shuttle Car, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as South Sudan, Seattle (United States), Luanda (Angola), Orlando (United States), Kazakhstan, Colombo (Sri Lanka), and so on. We are looking forward to cooperate with you. If you are interested in Shuttle Robot.

A Shuttle Robot, also known as an Autonomous Mobile Robot (AMR) or Shuttle System, is a type of robotic technology used in warehouses and distribution centers for material handling and logistics operations. It is designed to autonomously transport goods or materials within a facility, eliminating the need for manual labor and increasing efficiency.

Shuttle Robots offer several benefits, including increased productivity, reduced labor requirements, improved accuracy, and optimized space utilization. By automating material transport tasks, they enable workers to focus on higher-value activities and contribute to smoother and more efficient warehouse operations.

That the specific design and capabilities of Shuttle Robots may vary among manufacturers and based on the intended application and requirements of the facility.

Here are the key features and components of a Shuttle Robot:

1. Autonomous Navigation: Shuttle Robots are equipped with advanced navigation and mapping technology that allows them to move autonomously throughout the facility. They use sensors, cameras, and laser scanners to perceive their surroundings, avoid obstacles, and navigate around the facility safely.

2. Lifting and Transporting Capability: Shuttle Robots are designed to lift and transport goods or materials within the facility. They typically feature a flat platform or shelving system on top where the items can be placed. Depending on the design, they may have adjustable shelves or attachments to accommodate different types of loads.

3. Software Control System: The Shuttle Robot is controlled by a software system that manages its movement, task assignments, and overall operation. The software can be integrated with warehouse management systems (WMS) or other control systems to coordinate and optimize material handling operations. It allows for efficient routing, task prioritization, and real-time monitoring of the robots' status.

4. Swappable Batteries: Shuttle Robots are powered by rechargeable batteries. To minimize downtime, the robots are often designed with swappable battery systems. When a robot's battery is depleted, it can automatically navigate to a designated charging station, swap its battery with a fully charged one, and continue its tasks without interruption.

5. Safety Features: Shuttle Robots incorporate safety features to ensure the safety of personnel and equipment. These features may include sensors to detect and avoid collisions, emergency stop buttons, and audible or visual warnings to alert nearby workers of their presence.

6. Integration with Warehouse Infrastructure: Shuttle Robots can be integrated with the existing infrastructure of a warehouse or distribution center. They can interface with conveyor systems, racks, or other automated equipment to seamlessly move goods between different areas of the facility. This integration improves overall efficiency and material flow.