Products

Ebil Tech

High-Density Storage Rack

High-Density Storage Rack is one of our products, we can provide one-stop storage system solutions and products, our products also include VNA Pallet Rack, Four-Way Shuttle Racking System, Warehouse Drive-In Pallet Rack, Medium Duty Shelving Units, Telescoping beam rack, Medium-Duty Storage Rack, Teardrop-Style Rack, Medium Duty Storage Racks, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as La Paz (Bolivia), Oman, Ukraine, Turks and Caicos Islands, Islamabad/Islamabad (Pakistan), Germany, and so on. We are looking forward to cooperate with you. If you are interested in High-Density Storage Rack.

High-density storage racks are designed to optimize warehouse space utilization by maximizing storage capacity in a given area. These rack systems are specifically engineered to store a large volume of products or materials while minimizing aisle space. Here's some information about high-density storage racks:

1. Types of High-Density Storage Racks:

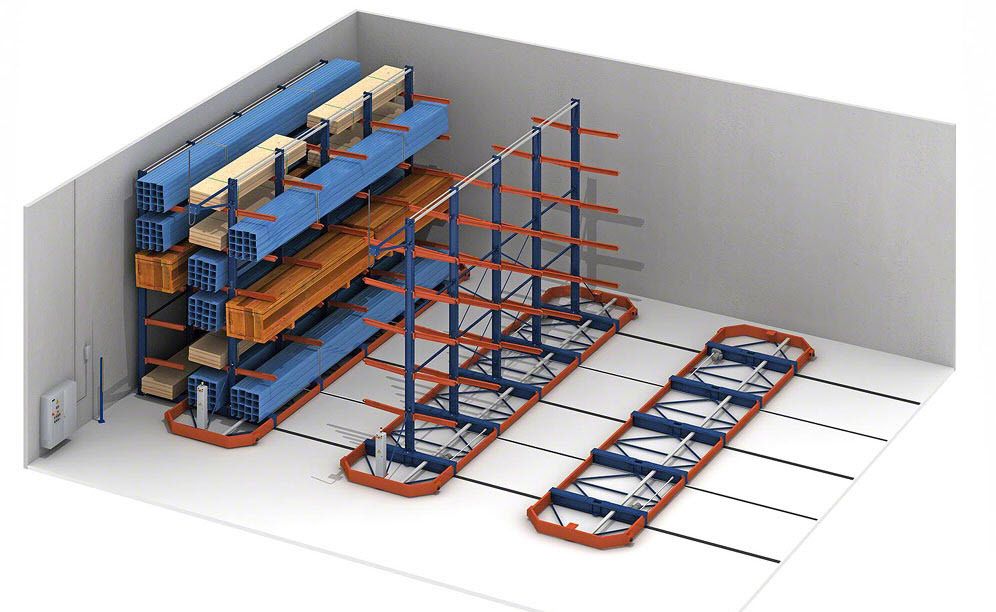

- Push Back Racking: Push back racks feature a series of nested carts or trays that are pushed back along inclined rails. When a new pallet is loaded onto the front cart, it pushes the existing pallets toward the back of the rack. This system allows for multiple pallets to be stored in a single lane, with each lane containing several levels of carts.

- Pallet Flow Racking: Pallet flow racks utilize inclined roller or wheel tracks, allowing pallets to flow from the loading end to the unloading end through gravity. The rear pallets are automatically pushed forward as the front pallets are removed, ensuring a continuous flow. This system is ideal for first-in, first-out (FIFO) inventory management.

- Drive-in/Drive-through Racking: Drive-in and drive-through racks are designed for high-density storage of homogeneous products with limited stock-keeping units (SKUs). Forklifts can drive directly into the rack structure to load and retrieve pallets. Drive-in racks have a single entry and exit point, while drive-through racks have entry points on both ends, allowing for a last-in, first-out (LIFO) inventory management system.

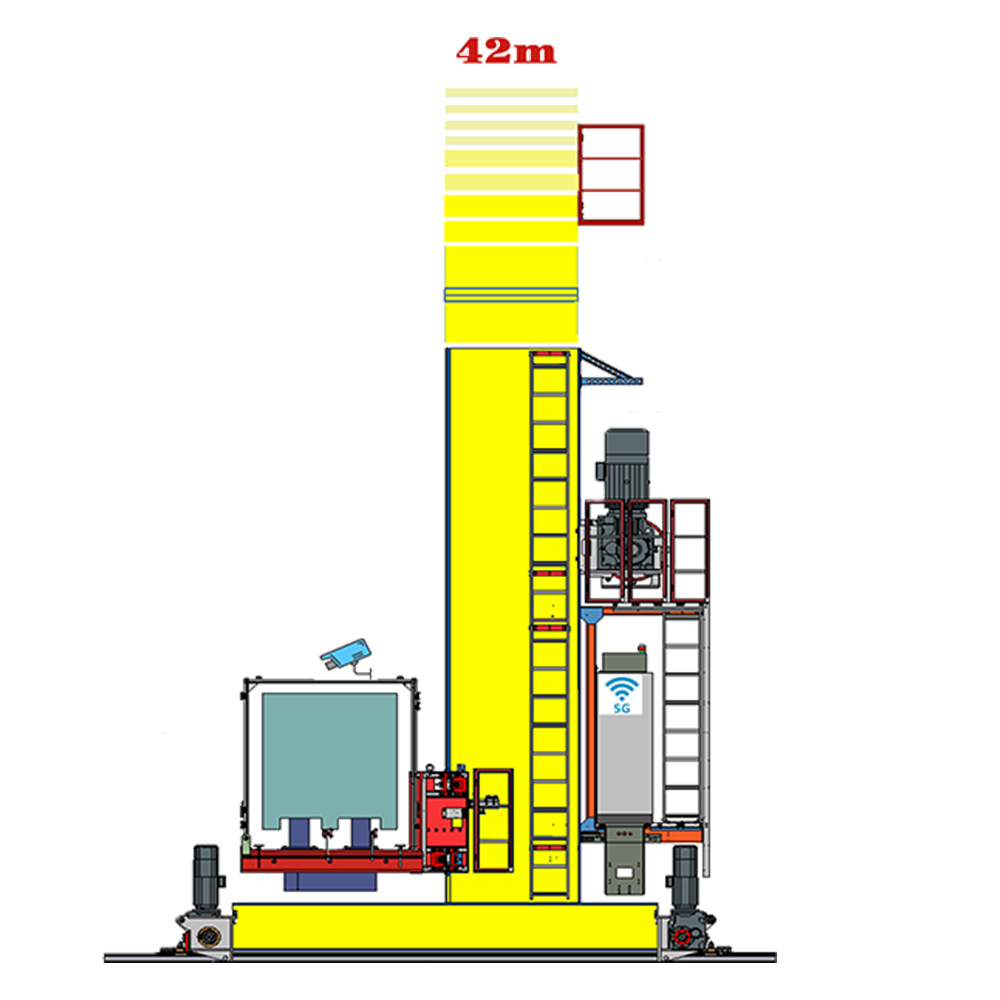

- automated storage and retrieval systems (AS/RS): AS/RS systems are highly automated and use robotic shuttles or cranes to handle pallets within the rack structure. These systems can operate in various configurations, such as single deep, double deep, or multi-deep storage, depending on the specific requirements.

2. Advantages of High-Density Storage Racks:

- Maximized Storage Capacity: High-density racks make efficient use of vertical and horizontal space, increasing storage capacity compared to traditional racking systems.

- Improved Space Utilization: By reducing the number of aisles required, high-density racks can free up valuable floor space for other operations or additional storage.

- Selectivity and Accessibility: Depending on the system, high-density racks can offer selectivity to individual pallets or provide a continuous flow of products for efficient picking and replenishment.

- Efficient Inventory Management: Certain high-density rack systems, such as push back or pallet flow racks, support FIFO inventory rotation, ensuring proper stock rotation and minimizing product spoilage.

3. Considerations:

- Load Characteristics: It is essential to consider the weight, size, and stability of the stored products when selecting a high-density storage rack system.

- Inventory Flow: Different high-density rack systems offer different inventory management methods, such as FIFO or LIFO. Choose a system that aligns with your inventory flow requirements.

- Equipment Compatibility: High-density rack systems may require specific handling equipment, such as forklifts or automated machinery. Ensure compatibility and consider any additional equipment costs.

The pricing for high-density storage rack systems can vary based on factors such as the type of system, dimensions, load capacity, customization requirements, and supplier or manufacturer. It is recommended to consult with suppliers or racking manufacturers to obtain accurate pricing based on your specific needs and project details. They can provide detailed quotations and assist in designing the most suitable high-density storage rack system for your warehouse.