Products

Ebil Tech

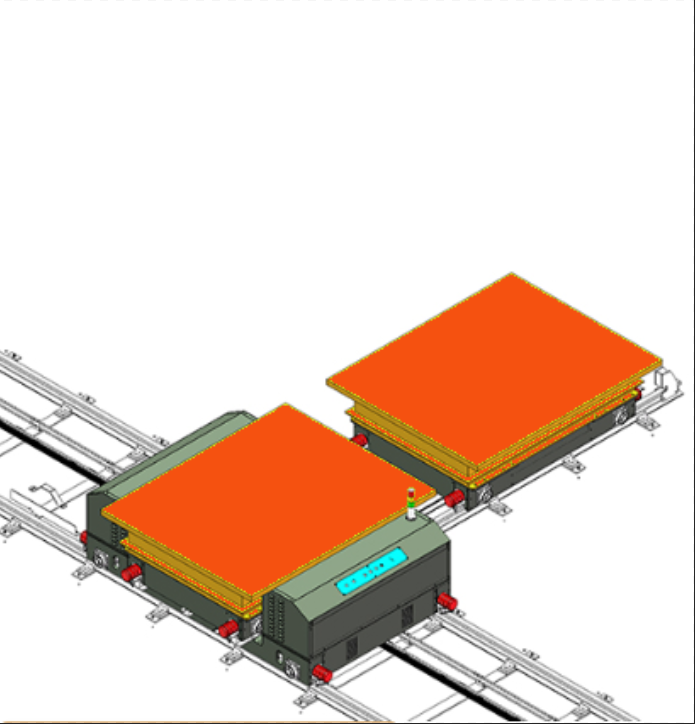

Automatic Radio Shuttle

Automatic Radio Shuttle is one of our products, we can provide one-stop storage system solutions and products, our products also include Medium-Duty Racking System, Intelligent Stacker, RGV System, Pallet Shuttle System, Cargo Elevator, Drawer Rack for Sheets, Shuttle Racking Solution, Telescoping Beam Rack, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Armenia, Norway, Birmingham (UK), Maltese Knights, Altay, Strasbourg (France), and so on. We are looking forward to cooperate with you. If you are interested in Automatic Radio Shuttle.

An Automatic Radio Shuttle, also known as an Automated Radio Shuttle System, is a type of Automated Storage And Retrieval System (AS/RS) that utilizes radio-controlled shuttle vehicles to handle the movement and storage of goods within a racking system. It is designed to optimize storage density and streamline material handling operations in warehouses or distribution centers.

The features and components of an Automatic Radio Shuttle system:

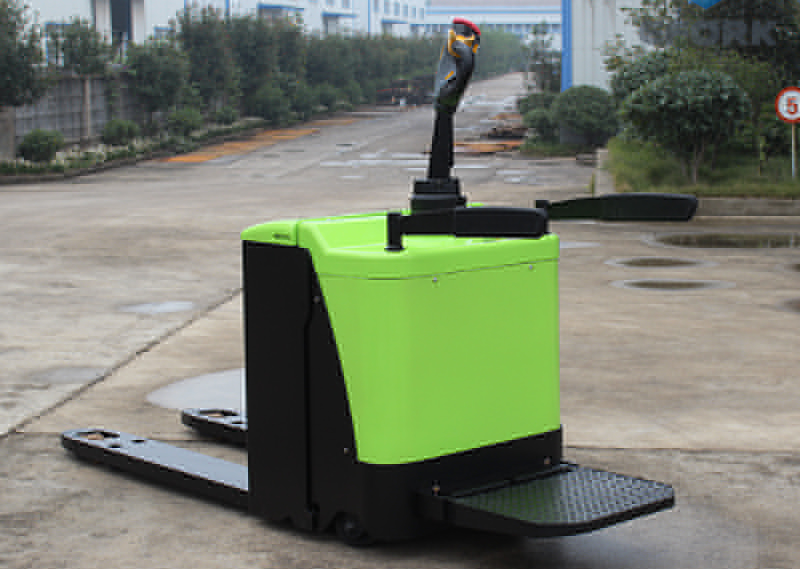

1. Radio-Controlled Shuttle Vehicles: The system employs autonomous shuttle vehicles that are radio-controlled and battery-powered. These shuttle vehicles operate within the storage lanes of the racking system, shuttling back and forth to transport and position pallets.

2. Racking System: The racking system in an Automatic Radio Shuttle system is designed to accommodate the shuttle vehicles and facilitate efficient storage and retrieval operations. It typically consists of deep lanes with storage positions on both sides, allowing the shuttle vehicles to access and handle pallets.

3. Radio Communication: The shuttle vehicles communicate wirelessly with a central control system via radio signals. The control system manages and coordinates the movements of the shuttle vehicles, ensuring efficient flow and optimization of material handling tasks.

4. Load Handling: The shuttle vehicles are equipped with mechanisms, such as forks or platforms, to handle and transport the pallets. They can lift, lower, and position the pallets within the storage locations. Some shuttle systems also have the ability to automatically transfer pallets between the shuttle vehicle and conveyor systems or other material handling equipment.

5. Control System: The control system acts as the brain of the Automatic Radio Shuttle system. It oversees and manages the operations of the shuttle vehicles, assigns tasks, optimizes retrieval and storage sequences, and interfaces with other warehouse management systems (WMS) or inventory control systems.

6. High Storage Density: Automatic Radio Shuttle systems are known for their high storage density. By utilizing the depth of the storage lanes and allowing shuttle vehicles to access multiple levels, they maximize the storage capacity of the warehouse. This enables efficient space utilization and can significantly increase the number of pallet positions available.

Automatic Radio Shuttle systems offer benefits such as increased storage capacity, improved efficiency, reduced labor requirements, and enhanced inventory management. They are particularly suitable for high-density storage environments with a high volume of palletized goods.

The specific features and functionalities of Automatic Radio Shuttle systems can vary among manufacturers and depend on the specific requirements of the facility.