Products

Ebil Tech

Shuttle System

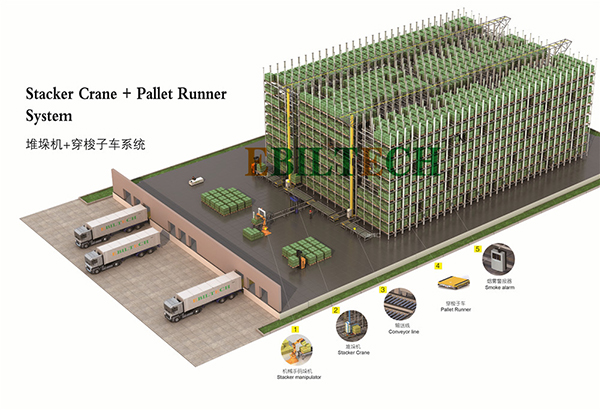

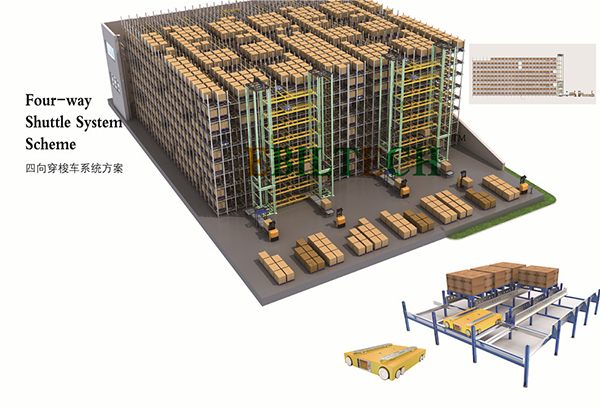

Shuttle System is one of our products, we can provide one-stop storage system solutions and products, our products also include Single Column Stacker, Drive In Racking System, Multi-Level Shuttle Rack, Miniload Stacker Crane, Automatic Radio Shuttle, Teardrop Style Rack, Adjustable cantilever rack, Mobile Shelving System, and so on. EBILTECH providing the automated and intelligent products of logistics system, such as pallet shuttle, stacker crane, cargo elevator, automatic transport system, other electrical automation and software of the logistics system. We have many main markets in the world, such as Malaga (Spain), Vancouver (British Columbia, Canada), Vienna (Austria), Canberra (Australia), Milwaukee (United States), Gambia, and so on. We are looking forward to cooperate with you. If you are interested in Shuttle System.

A shuttle system, also known as a pallet shuttle system or a shuttle racking system, is a type of automated storage and retrieval system (AS/RS) used for high-density storage of palletized goods in warehouses or distribution centers. It utilizes specialized shuttle vehicles to transport and position pallets within the racking system.

Here are the key components and features of a shuttle system:

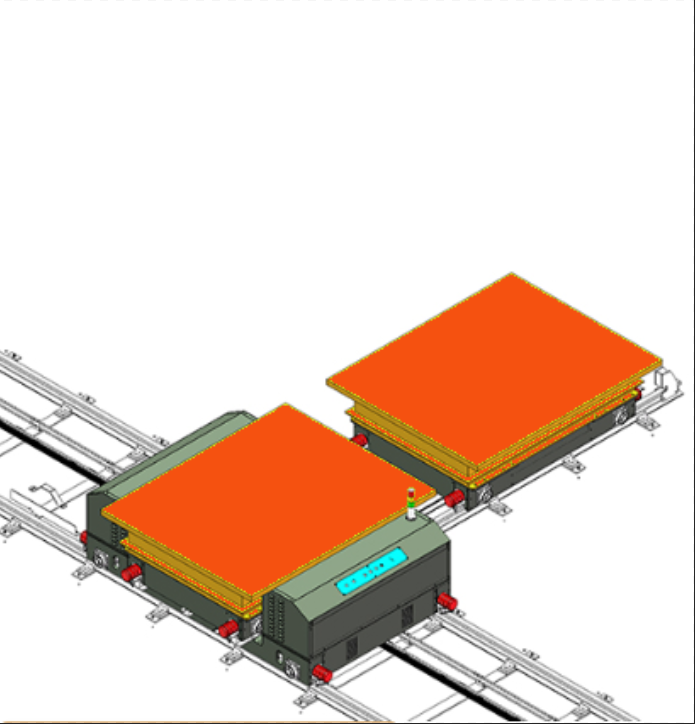

1. Shuttle Vehicles: The shuttle system consists of autonomous shuttle vehicles that operate within the storage lanes of the racking system. These shuttle vehicles are designed to travel horizontally along the depth of the racking system, carrying and handling the pallets. They are equipped with sensors, motors, and control systems that allow them to navigate through the lanes and perform the required tasks.

2. Racking System: The racking system in a shuttle system is designed with specific considerations for shuttle operations. It typically features a series of deep lanes with storage positions on both sides. The shuttle vehicles move within the lanes, accessing and retrieving the pallets from the designated storage positions.

3. Load Handling: Shuttle vehicles are equipped with mechanisms, such as forks or platforms, to handle and transport the pallets. They can lift and lower the pallets, position them in the storage locations, and retrieve them when needed.

4. Control System: The shuttle system is controlled by a centralized control system that manages the movement and operations of the shuttle vehicles. It coordinates the tasks, assigns priorities, and optimizes the workflow within the system. The control system can be integrated with other warehouse management systems (WMS) to ensure seamless coordination and efficient operations.

5. High Storage Density: Shuttle systems are known for their high storage density. By utilizing the depth of the storage lanes and allowing shuttle vehicles to access multiple levels, they maximize the storage capacity of the warehouse. This enables efficient utilization of the available space and allows for a large number of pallets to be stored in a relatively small footprint.

Shuttle systems offer benefits such as increased storage capacity, improved inventory management, faster order picking, and reduced labor requirements. They are particularly suitable for warehouses with a high volume of palletized goods and a need for efficient storage and retrieval operations.

It's important to note that there can be variations in shuttle system designs and features depending on the specific manufacturer and the requirements of the warehouse or distribution center.